Folding mechanism of scooter

A folding mechanism and scooter technology, applied in the field of machinery, can solve the problem of large space occupied by the scooter, and achieve the effects of simple structure, low manufacturing cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

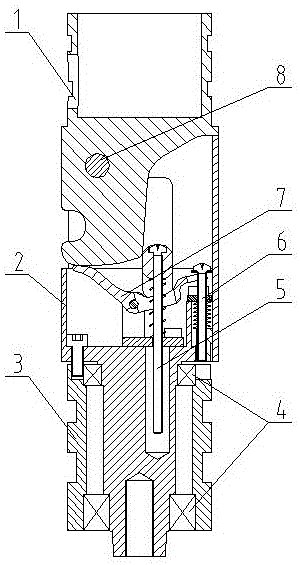

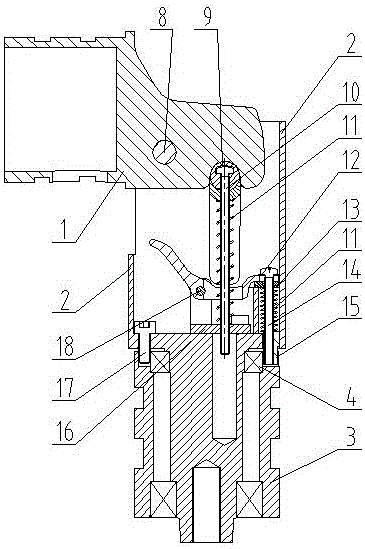

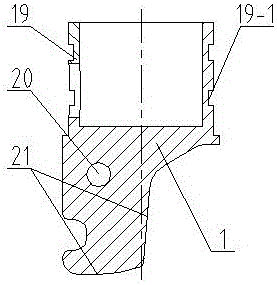

[0060] In the folding mechanism of the scooter of the present invention, the upper folding part 1 and the folding main body 2 are hinged by a pin 8, and the upper folding part 1 is provided with a limiting slope 21 and an elliptical half-length groove, and the folding main rod 10 The upper end is connected with the folding shaft 9, and the lower end is fixed on the folding main body 2 through the bracket 16. In order to make the scooter unfold and fold quickly and reliably, the folding main rod 10 and the limiting main rod 14 are also equipped with respective The spring 11 that main rod is suitable for. The two ends of the folding shaft 9 are assembled in the guide groove 23 of the folding main body 2, and the middle section can slide up and down in the limit slope 21 and the elliptical half-length groove to control the unfolding or folding of the folding mechanism. The folding main body 2 A bearing 4 is provided between the lower folding part 3, so that the lower folding part 3

Embodiment 2

[0062] In the folding mechanism of the scooter of the present invention, the upper folding part 1 and the folding main body 2 are hinged by a pin 8, and the upper folding part 1 is provided with a limiting slope 21 and an elliptical half-length groove, and the folding main rod 10 The upper end is connected with the folding shaft 9, and the lower end is fixed on the folding main body 2 through the bracket 16. In order to make the scooter unfold and fold quickly and reliably, the folding main rod 10 and the limiting main rod 14 are also equipped with respective The spring 11 that main rod is suitable for. The two ends of the folding shaft 9 are assembled in the guide groove 23 of the folding main body 2, and the middle section can slide up and down in the limit slope 21 and the elliptical half-length groove to control the unfolding or folding of the folding mechanism. The folding main body 2 A bearing 4 is provided between the lower folding part 3, so that the lower folding part 3

Embodiment 3

[0064] In the folding mechanism of the scooter of the present invention, the upper folding part 1 and the folding main body 2 are hinged by a pin 8, and the upper folding part 1 is provided with a limiting slope 21 and an elliptical half-length groove, and the folding main rod 10 The upper end is connected with the folding shaft 9, and the lower end is fixed on the folding main body 2 through the bracket 16. In order to make the scooter unfold and fold quickly and reliably, the folding main rod 10 and the limiting main rod 14 are also equipped with respective The spring 11 that main rod is suitable for. The two ends of the folding shaft 9 are assembled in the guide groove 23 of the folding main body 2, and the middle section can slide up and down in the limit slope 21 and the elliptical half-length groove to control the unfolding or folding of the folding mechanism. The folding main body 2 A bearing 4 is provided between the lower folding part 3, so that the lower folding part 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap