Pyrolysis experiment device monitoring system

A technology of a test device and a monitoring system, which is applied in the field of hardware implementation of the monitoring system, can solve the problems of inconvenient unified operation, single function, and inability to record and save historical data of temperature and humidity, so as to avoid repeated design and facilitate industrial promotion , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

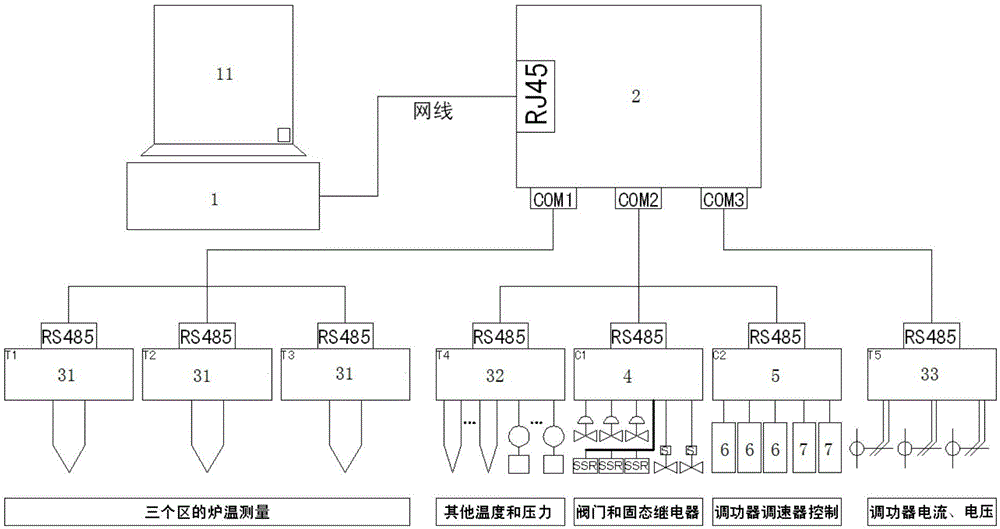

[0037] The specific implementations of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments, so as to better understand the solutions of the present invention and the advantages of various aspects thereof. However, the specific embodiments and examples described below are for illustrative purposes only, and are not intended to limit the present invention.

[0038] To better describe the present invention, first introduce the pyrolysis test device. The pyrolysis test device is composed of a pyrolysis furnace, a feeding part, a heating and conveying part, a slag discharge part, an oil gas discharge part, an auxiliary nitrogen gas and a steam part. The main body of the pyrolysis furnace is composed of three heating pipes wound by resistance wires, forming three temperature zones of the furnace body; feeding and heating are mainly composed of two screw conveyors. The temperature in the pyrolysis furnace is provided by

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap