Transposition unit of brake pump sealing ring loading machine

A sealing ring and brake pump technology, applied in the direction of conveyor objects, metal processing, metal processing equipment, etc., can solve the problems of low work efficiency and complex structure, and achieve the effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0010] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

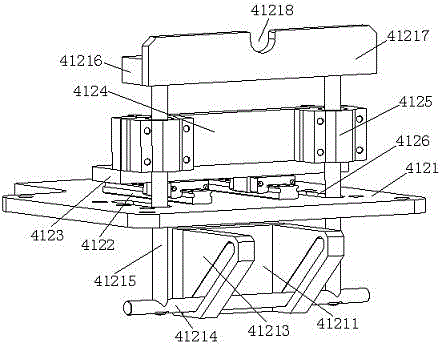

[0011] A transposition unit of a brake pump sealing ring feeder, the transposition unit of the brake pump seal ring feeder includes a transposition mounting plate 40, the lower plane of the transposition mounting plate 40 is fixed with a linear guide rail mounting plate 4121 through a pillar , the upper plane of the linear guide rail mounting plate 4121 is fixed with two horizontal linear guide rails 4122, the sliders of the two linear guide rails 4122 are fixed with a slide plate 4123, and the upper plane of the slide plate 4123 is fixed with a lifting bearing seat perpe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap