Battery test clamp

A battery test and battery technology, applied in the field of fixture tooling, can solve the problems of unable to collect temperature signals, invisible installation positions, and unable to install batteries, etc., to improve test safety and reliability, facilitate line tracking and inspection, and clear wiring organized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

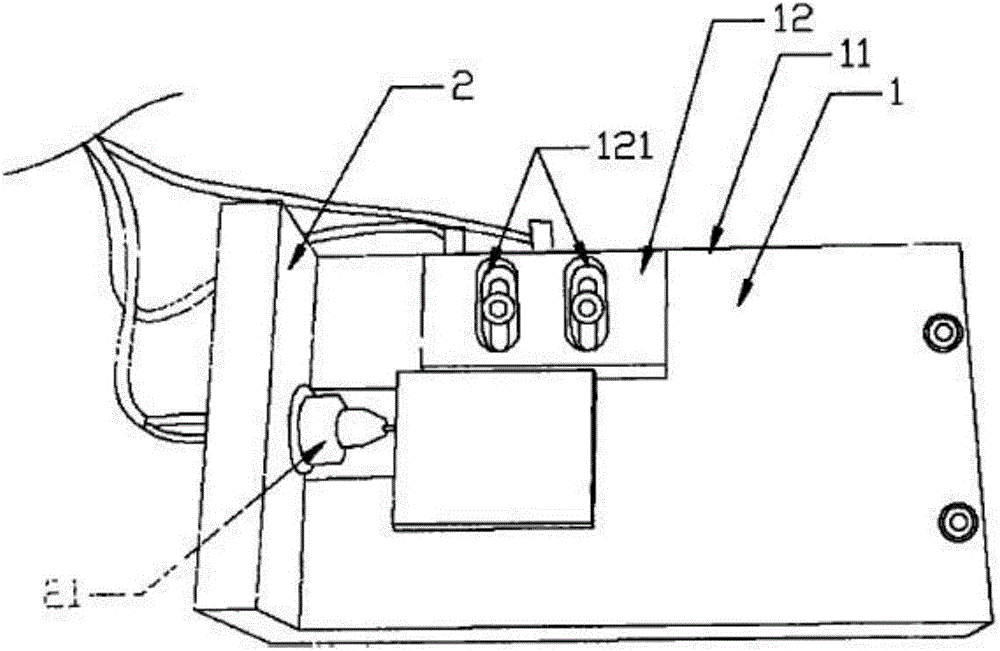

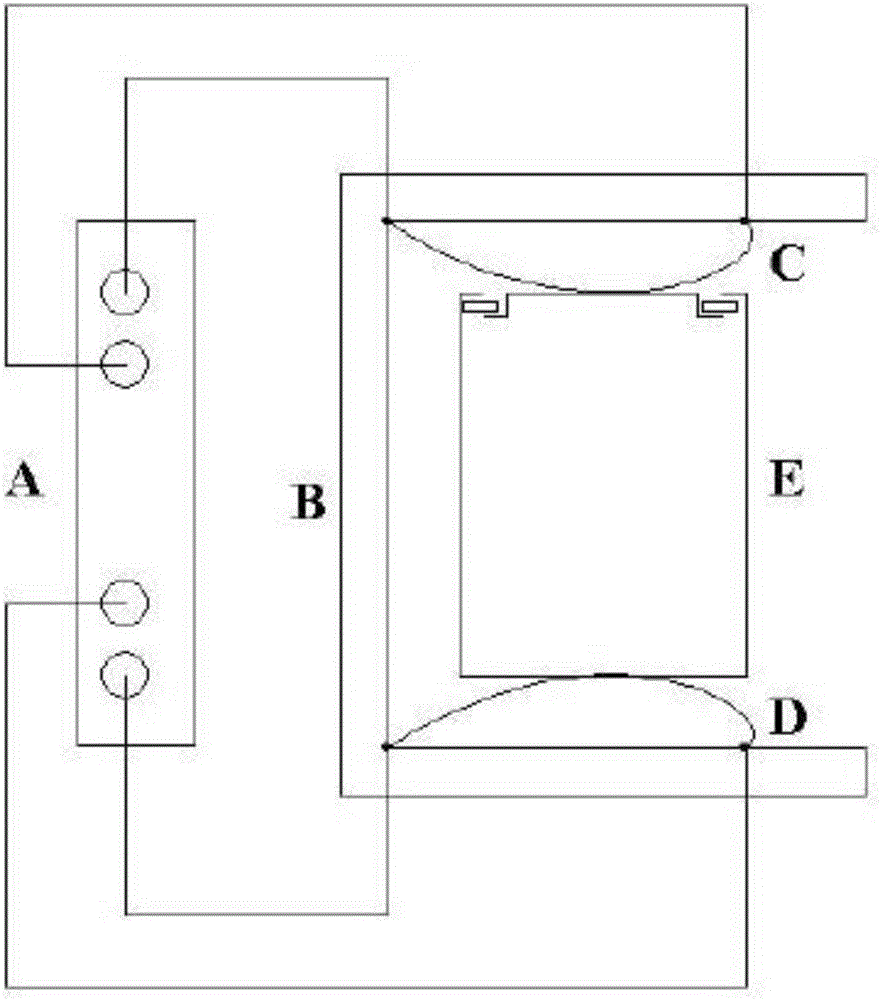

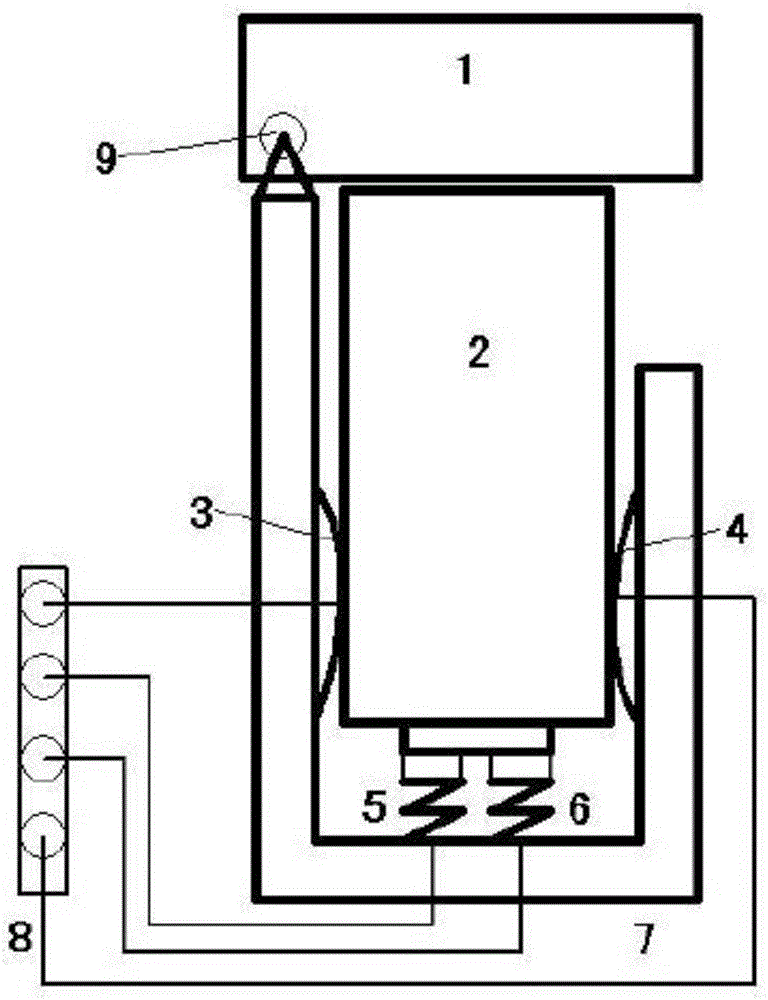

[0037] Figure 5 It is a structural schematic diagram of the present invention after installation. Figure 6 It is a schematic diagram of the disassembled structure of the present invention. The present invention includes a test base 1 and a battery clamping assembly 2, which are connected by screws 3 with pads. The test fixture of the present invention can be used in a constant temperature and humidity chamber (hereinafter referred to as a constant temperature chamber) or not in a constant temperature chamber, and the usage methods in the two cases are different. Firstly, the method of using the fixture in the incubator is introduced in detail. After the test base 1 is assembled first, it is f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap