Vehicle with switched supplemental energy storage system for engine cranking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

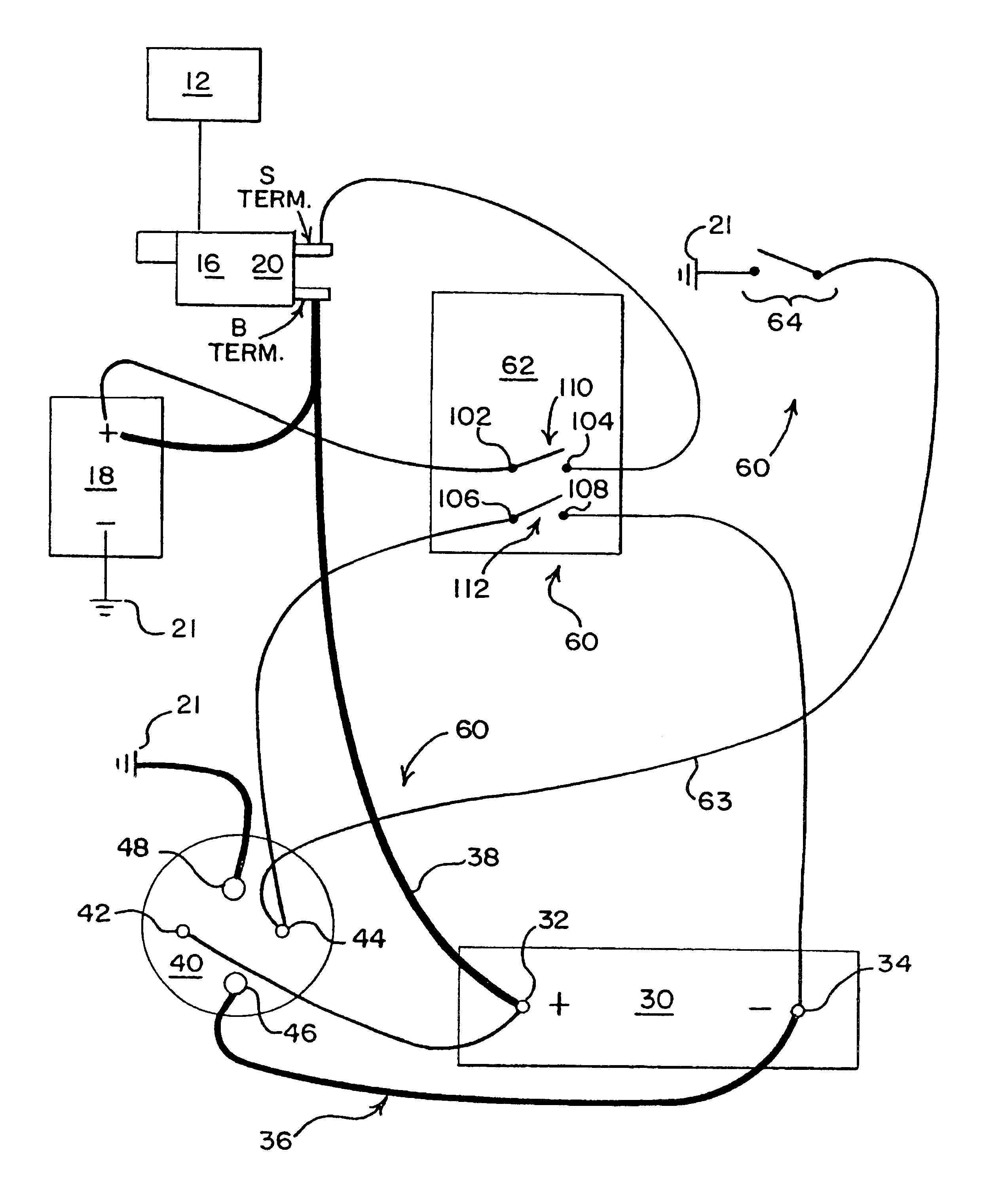

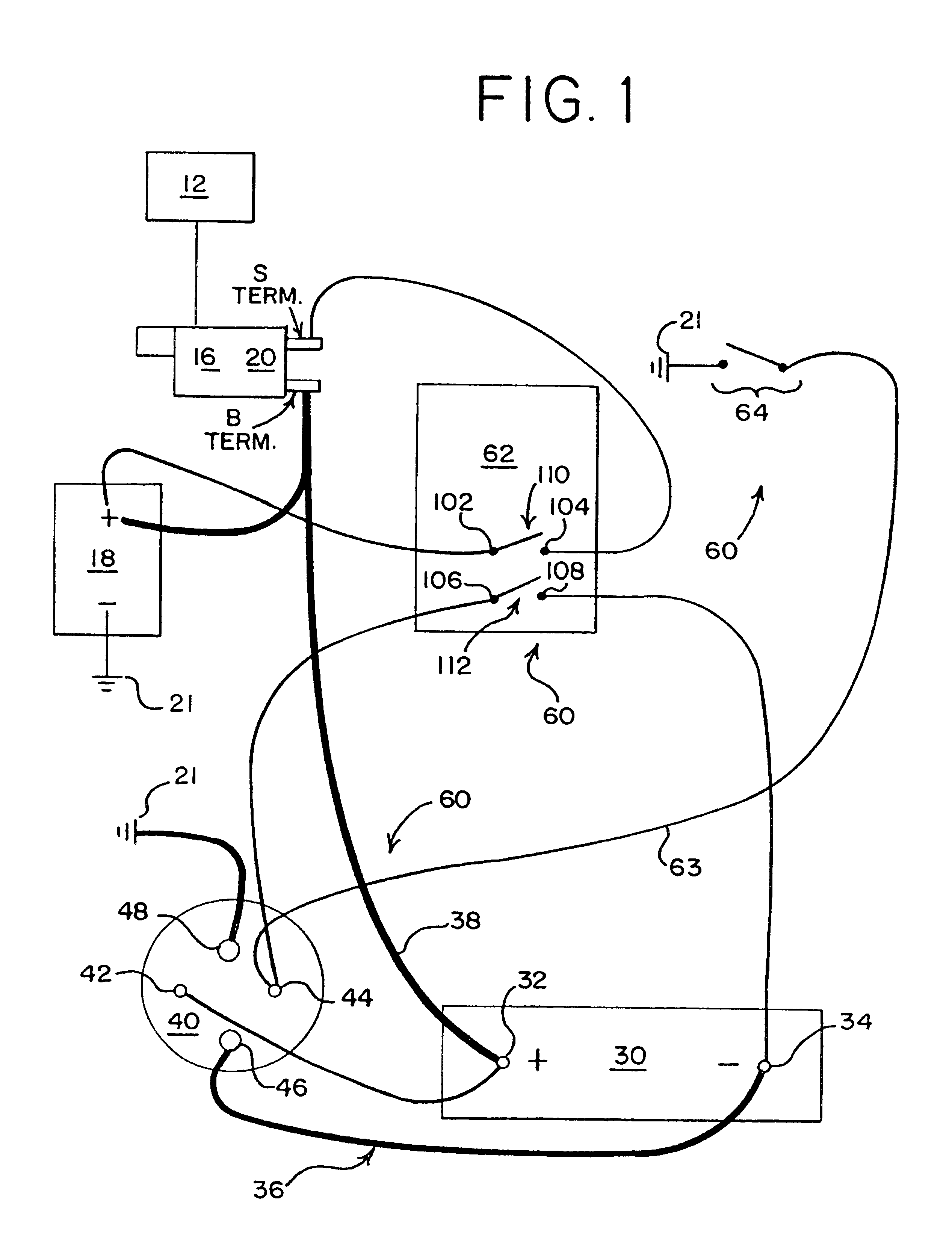

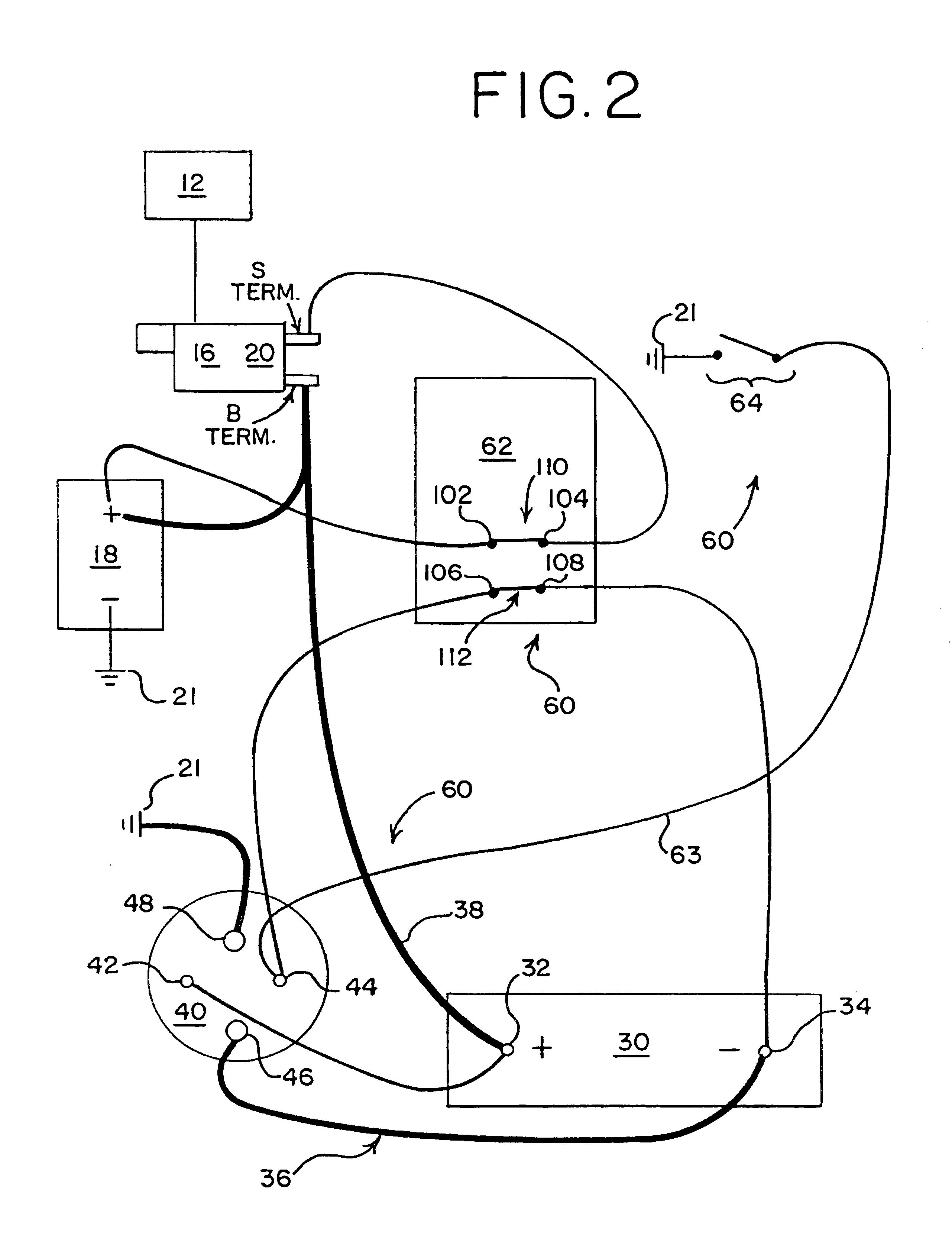

Turning down to the drawings, FIGS. 1-4 show an electrical system of a vehicle (not shown) that includes an internal combustion engine 12. The engine 12 can take any suitable form, and may for example be a conventional diesel or gasoline engine. The engine 12 is mechanically coupled to a cranking motor 16. The cranking motor 16 can take any suitable form, and it is conventionally an electrical motor that is powered during cranking conditions by current from one or more storage batteries 18 such as conventional lead-acid batteries. Current from the batteries 18 is switched to the cranking motor 16 via a switch such as a conventional solenoid switch 20. In operation, the engine is operably moved between a running condition and an off condition.

All of the elements 12 through 20 described above may be entirely conventional, and are well-known to those skilled in the art. The present invention is well adapted for use with the widest variety of alternative embodiments of these elements.

In ad

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap