Continuous extraction separator

A separation device and extraction technology are applied in the direction of carboxylic acid nitrile purification/separation, extraction water/sewage treatment, liquid solution solvent extraction, etc. Less dosage, high extraction efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

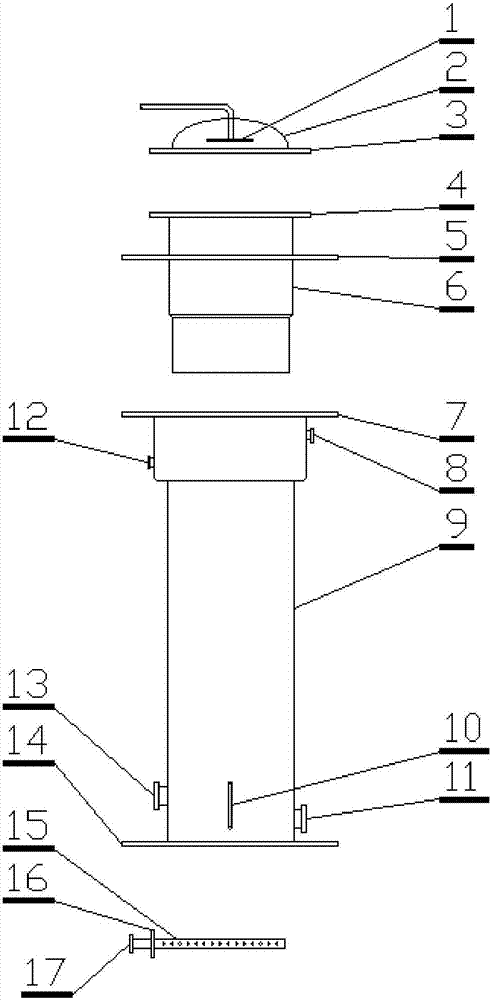

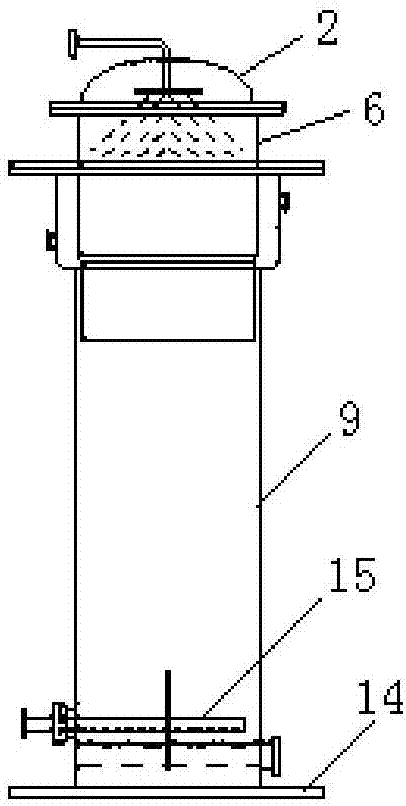

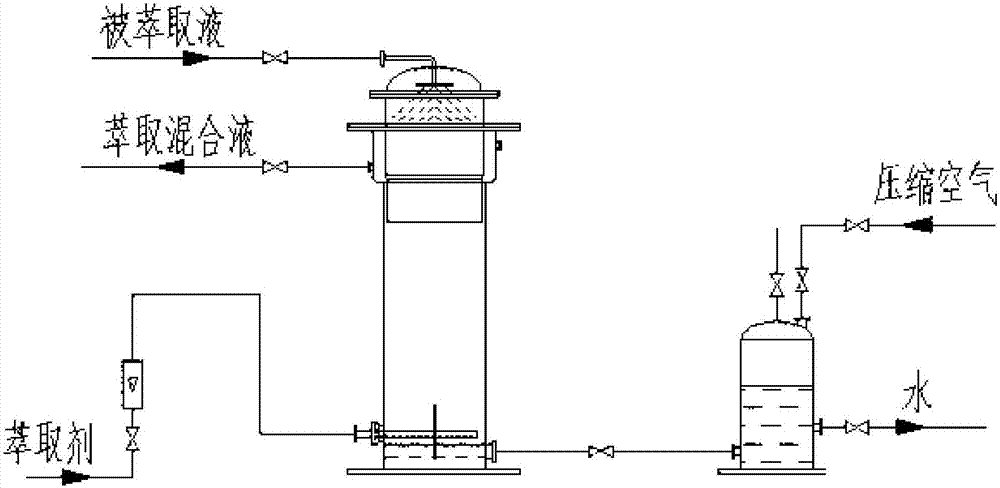

[0022] The present invention will be further described below in conjunction with the drawings:

[0023] As shown in the drawings, the present invention provides a continuous extraction and separation device, specifically a device that uses a hydrophobic organic solvent to extract the organic solvent in the water phase. The device includes a spray component and an extraction guide component. 6. The cylinder assembly 9 and the extraction agent distribution assembly 15, the spray assembly, the extraction guide assembly 6, the cylinder assembly 9, and the extraction agent distribution assembly 15 are connected in sequence from top to bottom. The spray assembly is connected by the shower head 1 and the sealing The spray head 1 is connected to the top of the head 2, and the bottom of the head 2 is provided with a flange 3. The extraction and diversion assembly 6 includes a diversion sleeve one and two diversion sleeves arranged up and down. The first sleeve is connected with the second gu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap