Cooking vessel for induction hobs and a method for making the cooking vessel

A technology for cooking utensils and induction furnaces, applied in the field of cooking utensils for induction furnaces and for manufacturing the cooking utensils, capable of solving problems such as negative impact on food quality, impact on production costs, long production time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

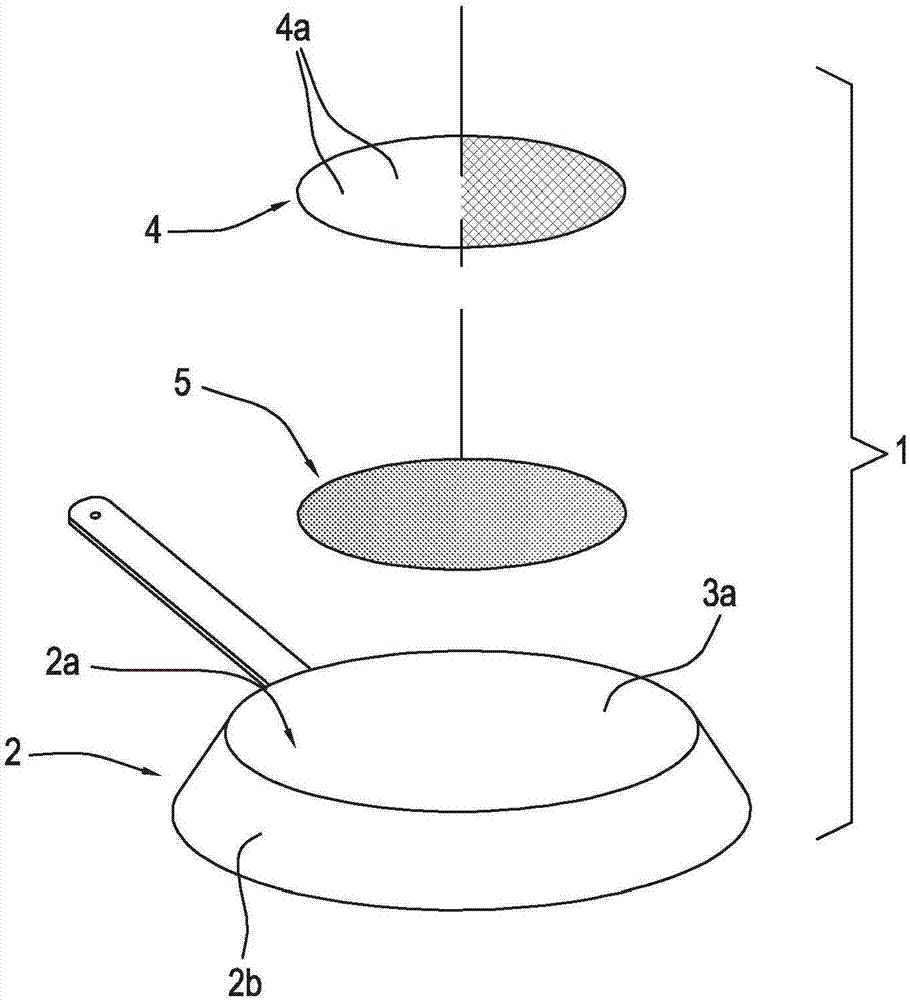

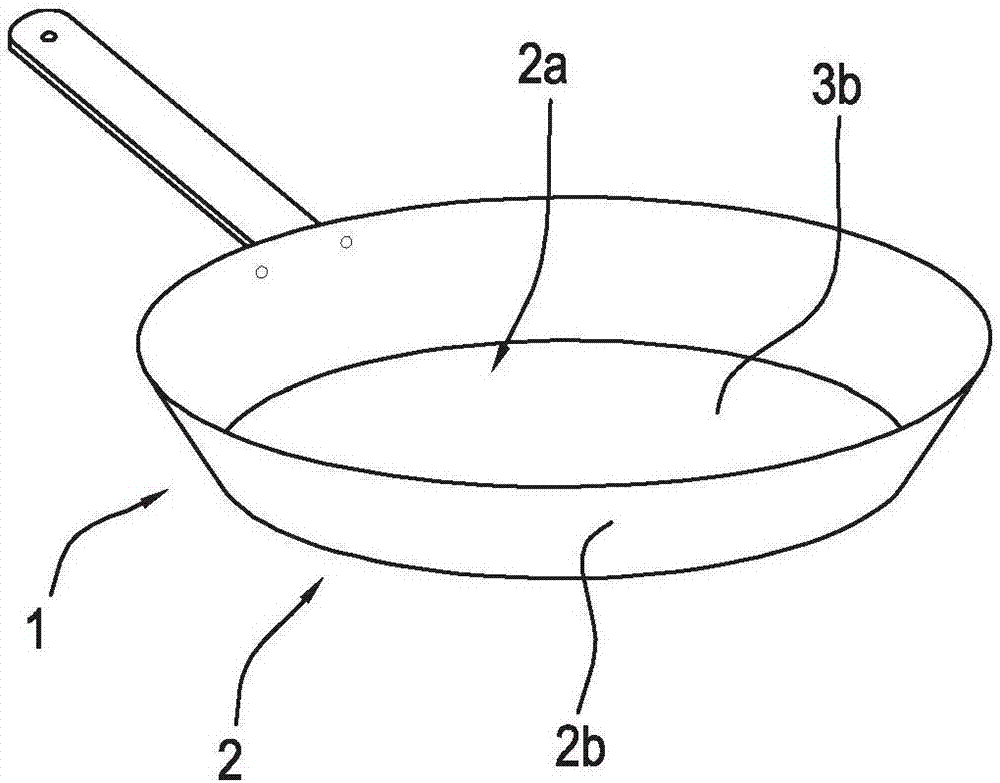

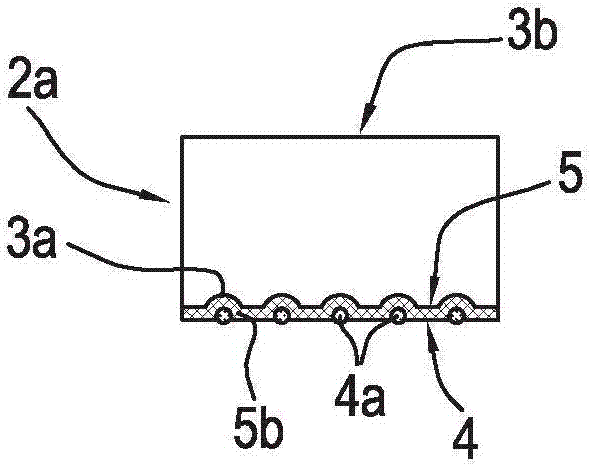

[0040] Referring to the drawings, numeral 1 denotes a cooking vessel for an induction stove according to the present invention.

[0041] As is well known, induction type cookers apply the principle of electromagnetic induction to heat vessels for cooking food.

[0042] The cooking vessel 1 according to the invention can therefore have any shape and size, provided that it is equipped with at least one ferromagnetic part.

[0043] For example, cooking utensils can be:

[0044] - small saucepan;

[0045] - cauldron;

[0046] - pans;

[0047] - Frying pan;

[0048] -pot;

[0049] - pressure cooker;

[0050] - Fish cooking pot;

[0051] - A platter or other vessel.

[0052] In the illustrated embodiment specific reference is made to a frying pan, but this is not intended to limit the scope of the invention.

[0053] The cooking vessel 1 comprises a concave receiving body 2 for receiving, which is provided with at least a bottom wall 2a and a side wall 2b.

[0054] Thus, the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap