Novel composite structure screen printing plate

A composite structure, screen technology, applied in screen printing, screen printing machine, rotary printing machine and other directions, can solve the problems of different degrees of stretching, easy fatigue cracking, broken pulp and other problems, to improve the service life, The effect of reducing production costs and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments will be clearly and completely described below with reference to the drawings in the embodiments. Obviously, the described embodiments are only a part of the present application. examples, but not all examples. Based on the given embodiments, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present application.

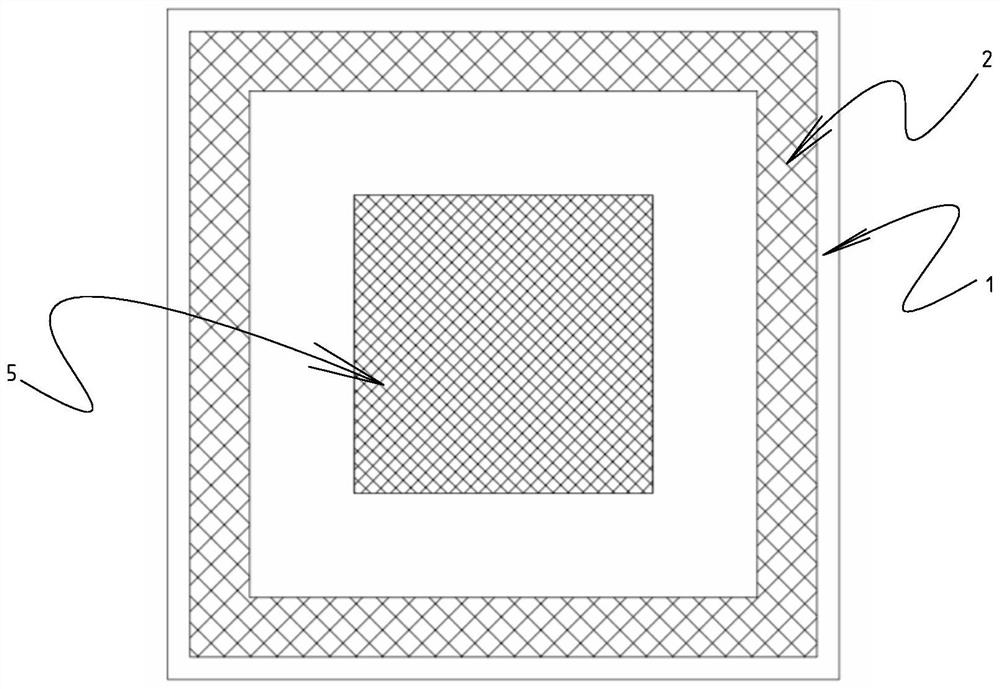

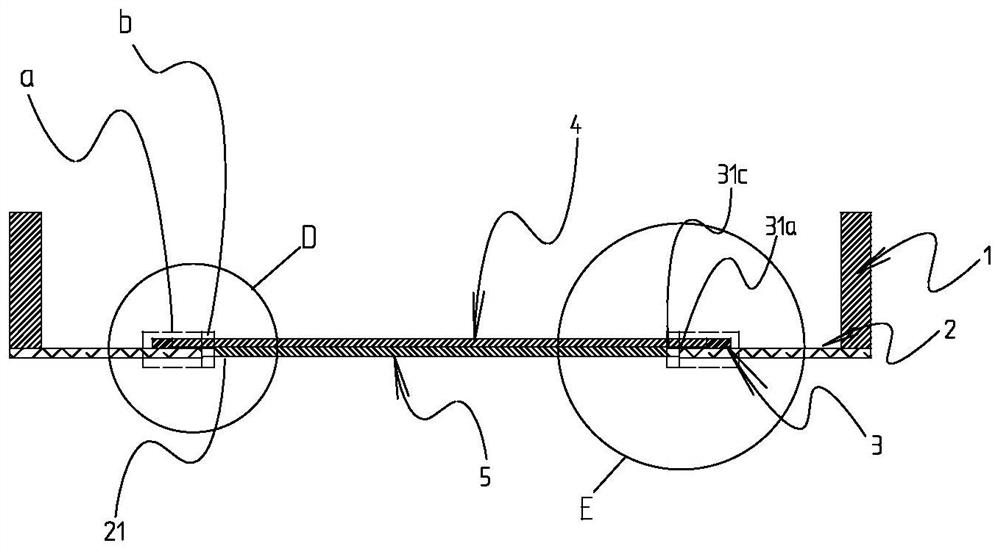

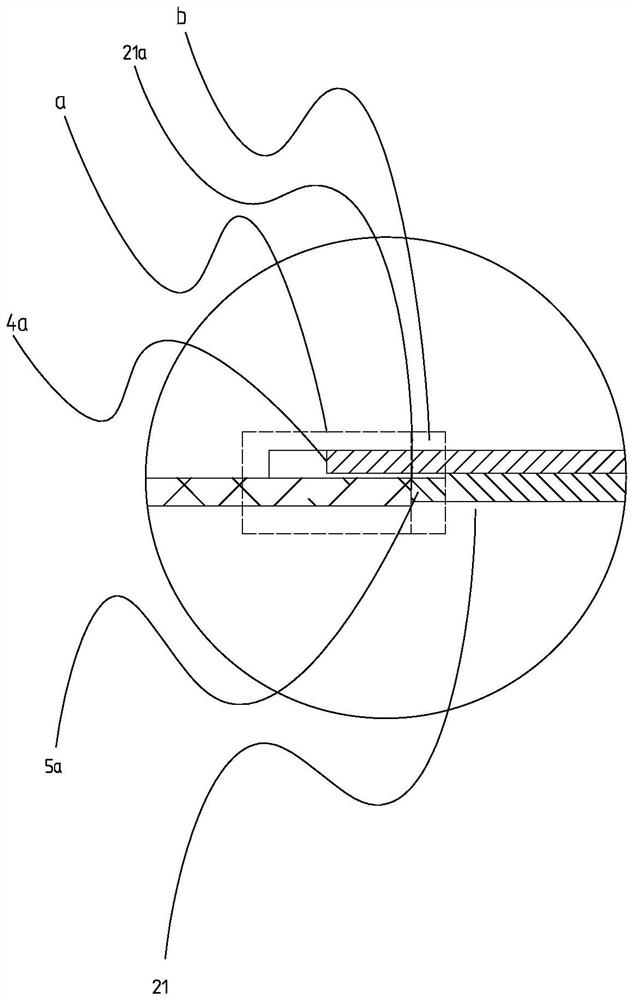

[0018] A new type of composite structure screen plate, comprising a metal mesh frame 1, polyester mesh cloth 2, metal mesh cloth 4 and graphic carrier polymer film 5; also includes a hot-melt polymer film 3; polyester mesh cloth 2 stretched After reaching the predetermined tension value, the edge is fixedly connected to the metal mesh frame 1. In this embodiment, the polyester mesh cloth 2 is preferably fixedly connected to the metal mesh fra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap