Plant community assimilation box with built-in light source

A plant community and built-in light source technology, applied in the field of plant assimilation boxes, can solve the problems of decreasing the reliability of measurement results, raising the condensation water on the inner wall of the box, changing the light transmittance, etc., to avoid the greenhouse effect, ensure uniformity, enhance The effect of light reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

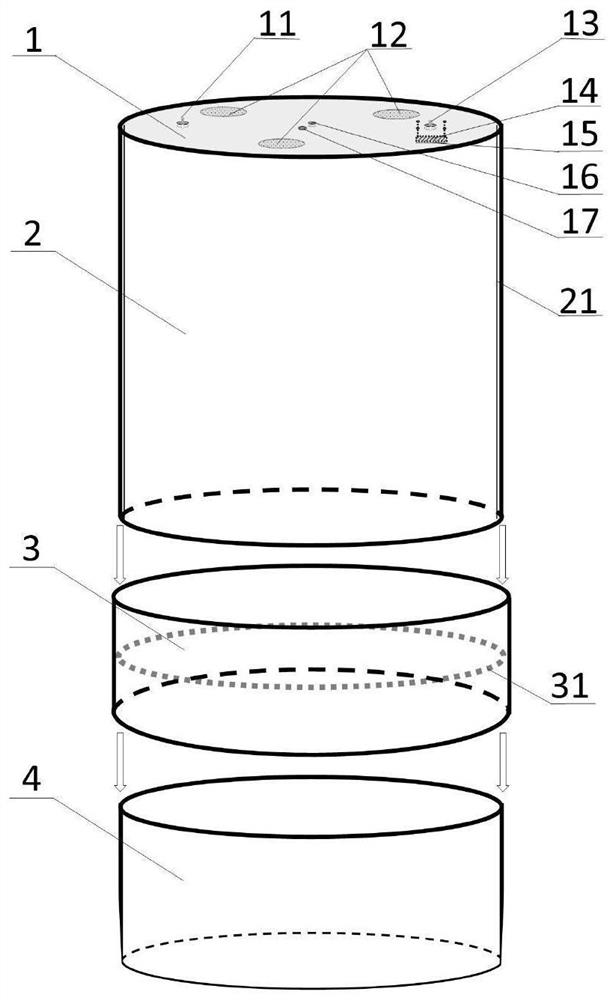

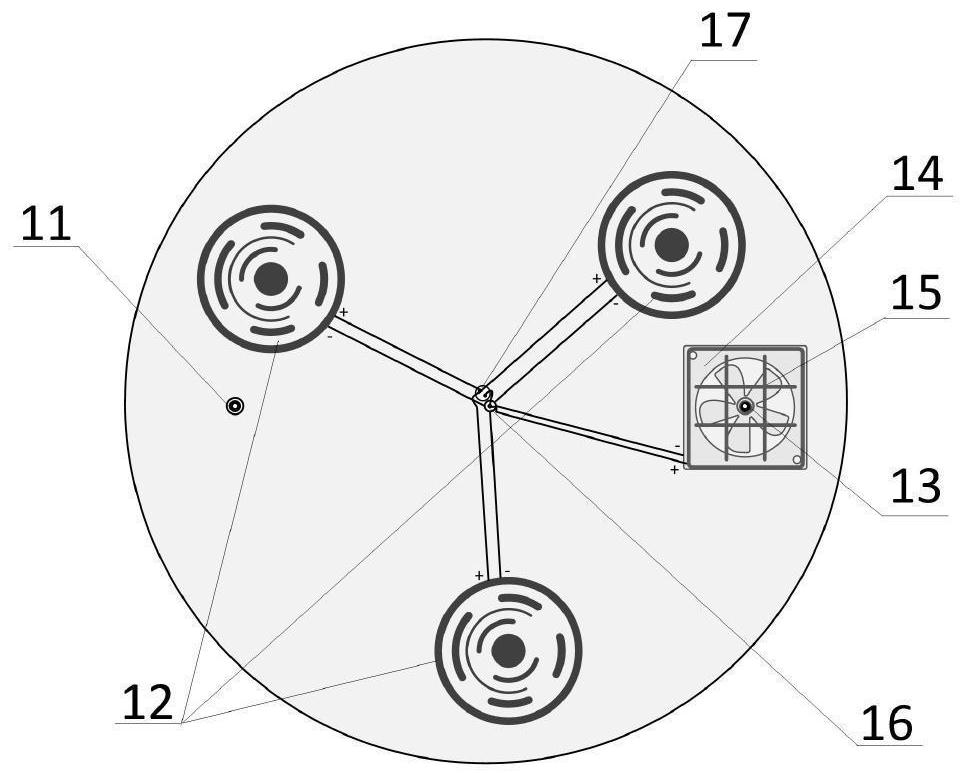

[0020] A plant community assimilation box with a built-in light source, comprising an aluminum top cover 1, an assimilation box body 2, a direct connector 3 and an assimilation box base 4, the aluminum top cover 1 is sealed and fixed on the top of the assimilation box body 2 The main body of the assimilation box is formed, and the main body of the assimilation box is sealed and connected with the base 4 of the assimilation box through a direct connection piece 3. The aluminum top cover 1 is equipped with a gas outlet quick-plug connector 11, a light source 12, and a gas inlet quick connector. Plug connector 13, mixing fan 14, fan metal mesh 15, DC power supply DC connector 16, light source switch 17, the light source 12 adopts LED constant current drive light source module, according to the measurement needs and the size of the assimilation box 2 select different

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap