Automatic ore screening machine

A screening machine and ore technology, applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve problems such as insufficient processing capacity, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

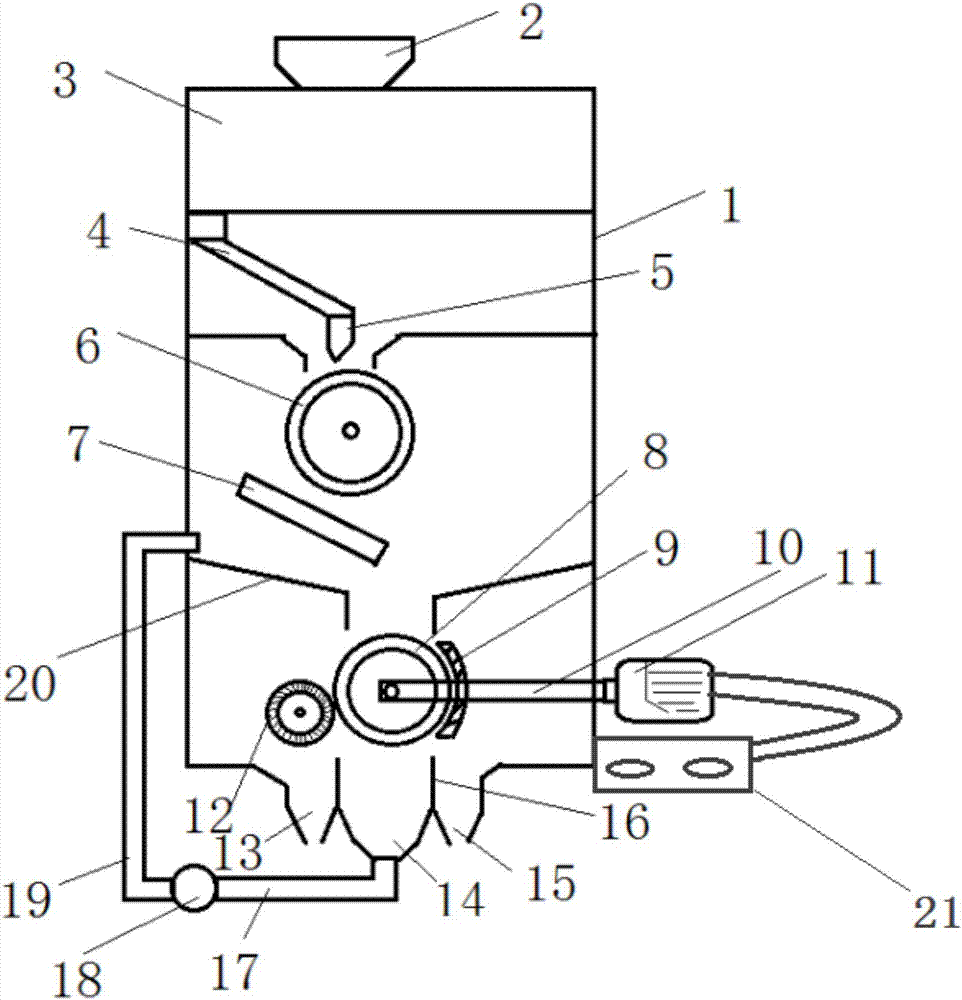

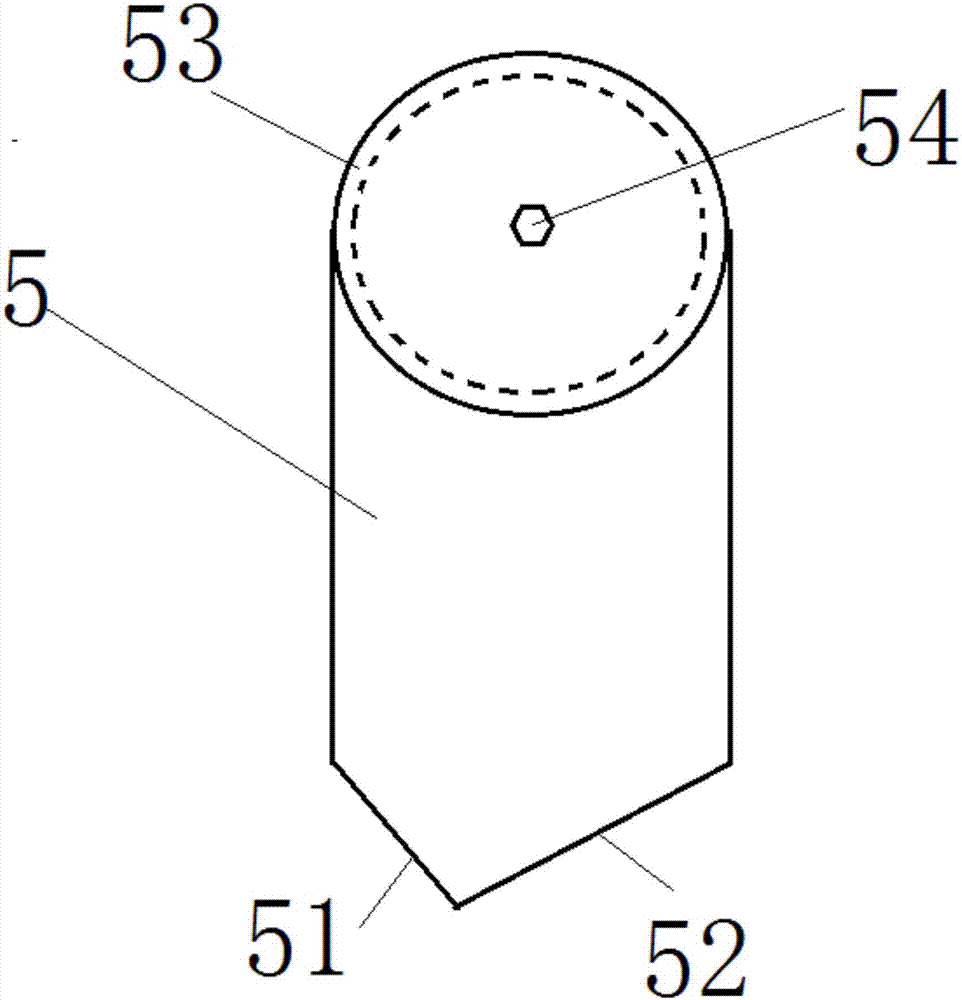

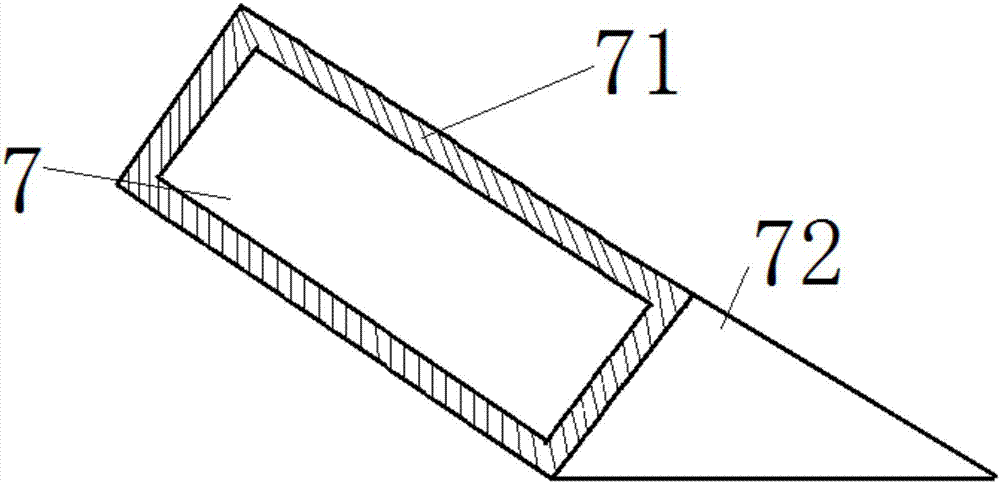

[0016] see Figure 1-4 , an automatic ore screening machine, including a casing 1, a feed hopper 2, a feed bin 3, a splitter 4, an adjustment member 5, a first drum 6, a heating bin 7, a second drum 8, a corona compound Electrode 9, driving motor 11 and solid particle conveying pump 18, described feeding bin 3 is positioned at the top of casing 1, and feeding hopper 2 is arranged at the top of feeding bin 3, and the outlet of feeding bin 3 is connected with splitter 4 , the adjusting part 5 is arranged below the splitter 4, and the adjusting part 5 includes a fixed nozzle 51, an adjusting nozzle 52, an eccentric knob 53 and a fixed shaft 54, the fixed nozzle 51 is fixed under the splitter 4, and the eccentric knob 53 is fixed by The shaft 54 is rotatably arranged at the lower end of the fixed nozzle 51, the regulating nozzle 52 is connected with th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap