Rearview mirror special for truck and capable of being adjusted in a lifting mode

A technology for lifting and adjusting rearview mirrors, which is applied in the field of automobile rearview mirrors, can solve the problems of rearview mirrors' dead angle field of vision and easy accidents, and achieve the effects of convenient use, simple structure, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

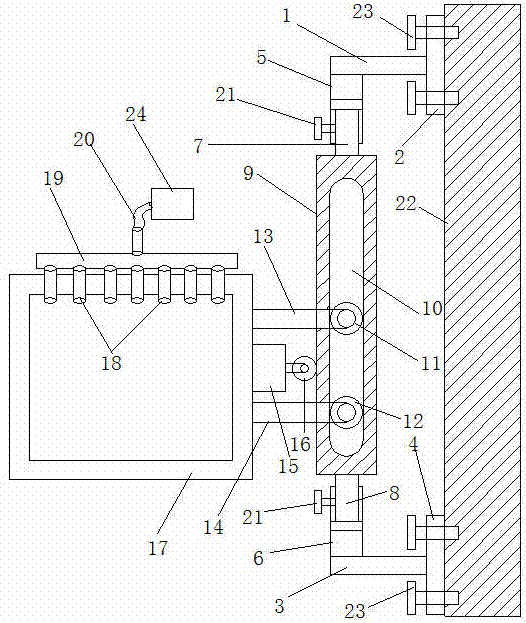

[0011] Such as figure 1 As shown, a special rearview mirror for large trucks that can be lifted and adjusted, its structure includes: an upper connecting column 1, an upper mounting plate 2, a lower connecting column 3, a lower mounting plate 4, an upper rotating cylinder 5, a lower rotating cylinder 6, Upper rotating column 7, lower rotating column 8, lifting adjustment plate 9, sliding hole 10, upper roller 11, lower roller 12, upper supporting column 13, lowe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap