Bionic adhesion-reducing resistance-reducing kneading machine

A technology of reducing viscosity and resistance, kneading machine, applied in the structural parts of mixing/kneading machinery, dough mixers, mixing/kneading with vertical installation tools, etc. Good, the effect is not obvious, the cost increases, etc., to reduce the adhesion quality, the effect is obvious, and the effect of reducing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

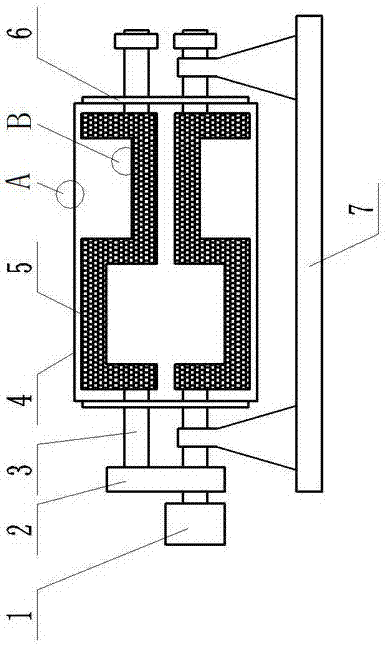

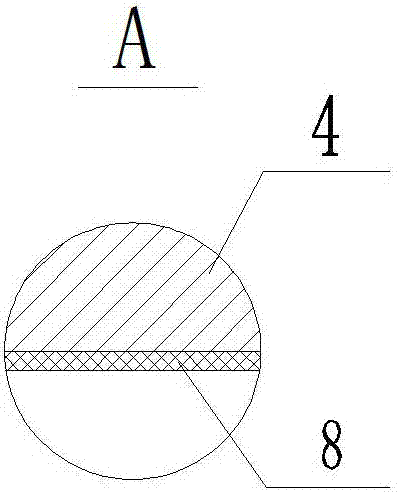

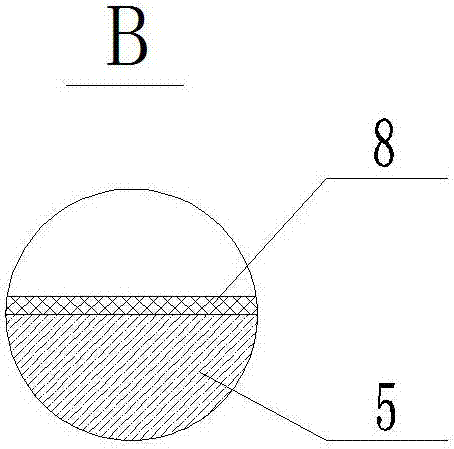

[0016] see figure 1 , figure 2 and image 3 shown. The present invention is composed of motor 1, transmission 2, kneading roller 3, mixing barrel 4, kneading paddle 5, end cover 6, machine base 7 and grid structure 8, the surface of the inner wall of mixing bucket 4 and the surface of kneading paddle 5 are all belted There is a uniform grid-like structure8.

[0017] The grid-like structure 8 is composed of interlaced horizontal ridges and vertical ridges, and the tops of the horizontal ridges and the vertical ridges have wave-shaped semicircular convex structures. The transverse ridges and the longitudinal ridges are arranged vertically to each other, have the same size and the same spacing.

[0018] The width of the horizontal and vertical ridges is 300 μm, the net height is 500 μm, the distance between the horizontal ridges and the vertical ridges is 600 μm, and the distance between the vertical ridges is 600 μm.

[0019] The diameter of the wavy semicircular protrusion i

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap