High performance fiber composite guardrail

A high-performance fiber and guardrail technology, applied in roads, road safety devices, roads, etc., can solve the problems of insufficiently advanced and perfect test methods and equipment, no theoretical basis and practical experience, and no breakthrough in better materials. The effect of avoiding ignition of fuel deflagration, reducing manpower and financial resources, and low comprehensive investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] The high-performance fiber composite guardrail provided in this embodiment includes the following components in parts by weight: 85 parts of ultra-high molecular weight polyethylene fiber; 80 parts of vinyl ester resin (VER).

[0027] The preparation method is as follows:

[0028] Weave ultra-high molecular weight polyethylene fibers into plain or twill cloth; dilute the silane coupling agent with ethanol (the volume ratio of silane coupling agent and ethanol is 1:4), and coat ultra-high molecular weight polyethylene with a soft roller After soaking the surface of the fiber cloth, heat the ultra-high molecular weight polyethylene fiber cloth to 80 degrees to remove ethanol, use a soft roller to evenly coat the vinyl ester resin (VER) mixture on the UHMWPE cloth, and then Hot press molding under the conditions of 100°C and pressure of 2.4MPa to prepare a thin layer of composite material, and then put the multi-layer material into a wave-shaped mold at a temperature of 110-1

example 2

[0030] The high-performance fiber composite guardrail provided in this embodiment includes the following components in parts by weight: 90 parts of ultra-high molecular weight polyethylene fiber; 85 parts of vinyl ester resin (VER).

[0031] The preparation method is as follows:

[0032] Weave ultra-high molecular weight polyethylene fibers into plain or twill cloth; weave various patterns of cloth made of multi-layer ultra-high molecular weight polyethylene fibers treated with the same coupling agent as in Example 1, and pour vinyl into them through a winding machine. In the trough of the ester resin (VER) mixture, it is evenly spread by multiple soft rollers, and then drawn into the wave-shaped shaping mold with a length of more than 15 meters by a drafting machine. The mold temperature is 110-130 ° C, and the mold pressure is 2 -3Mpa, the pulling speed is 3m / min. After the mold is released, it is cut by a fixed-length cutting saw, and it is automatically turned over and unlo

example 3

[0034] The high-performance fiber composite guardrail provided in this embodiment includes the following components in parts by weight: 75 parts of ultra-high molecular weight polyethylene fiber, and 100 parts of polymethyl methacrylate (PMMA).

[0035] The preparation method is as follows:

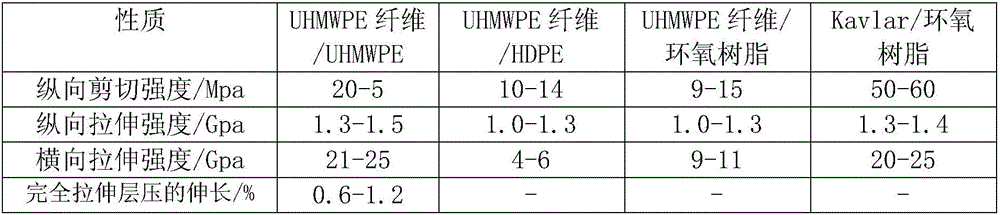

[0036] The ultra-high molecular weight polyethylene fibers are woven into plain or twill cloth; the multilayer ultra-high molecular weight polyethylene fiber cloth and polymethyl methacrylate (PMMA ) with a ratio of 75:100, put the fiber (or cloth) and resin into the wave-shaped mold and pressurize it. The mold temperature is 110-130°C, the pressure is 2.5-4Mpa, and the time is 2-6 minutes. After demoulding, it is the finished product. The longitudinal shear strength of the finished product is 12-17Mpa, and the longitudinal tensile strength is 1.0-1.3Gpa.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap