Condensed purple sweet potato milk

A purple potato and condensed milk technology, applied in dairy products, applications, milk preparations, etc., can solve the problems of single type and taste, and achieve the effect of high sensory score, short production cycle and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

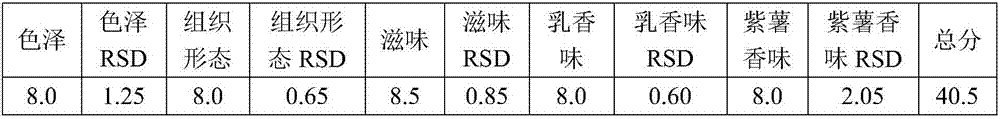

Examples

Example Embodiment

[0028] Example 1

[0029] A kind of purple potato condensed milk is prepared according to the following method:

[0030] (1) Preparation of Purple Potato Additives

[0031] Take purple potato, carry out crushing, beating, and solid-liquid separation treatment to obtain purple potato slurry and purple potato residue, add purple potato residue to 3.5 times the amount of dilute hydrochloric acid solution with pH value of 3.5, and at 42 ° C temperature Ultrasonic extraction was carried out for 25 minutes, and then filtered to obtain an extract. The pH value of the extract was adjusted to 5.5 with 0.1 mol / L potassium hydroxide solution, dried into powder, mixed with purple potato slurry, stirred evenly, and passed through a 100-mesh sieve. Filter, and finally add tea polyphenols, sodium guanylate and malic acid, the addition amount of tea polyphenols is 0.005%, the addition amount of sodium guanylate is 0.15%, and the addition amount of malic acid is 0.13%, all by weight , the sam

Example Embodiment

[0041] Example 2

[0042] A kind of purple potato condensed milk is prepared according to the following method:

[0043] (1) Preparation of Purple Potato Additives

[0044] Take purple potato, carry out crushing, beating, and solid-liquid separation treatment to obtain purple potato slurry and purple potato residue, add purple potato residue to 3 times the amount of dilute hydrochloric acid solution with pH value of 4, and at 40 ° C temperature Ultrasonic extraction was carried out for 30 minutes, and then filtered to obtain an extract. The pH value of the extract was adjusted to 5 with 0.1 mol / L potassium hydroxide solution, dried into powder, mixed with purple potato slurry, stirred evenly, and passed through a 100-mesh sieve. Filter, and finally add tea polyphenols, sodium guanylate and malic acid, the addition amount of tea polyphenols is 0.003%, the addition amount of sodium guanylate is 0.1%, the addition amount of malic acid is 0.1%, and the temperature is 40 ℃. Let st

Example Embodiment

[0054] Example 3

[0055] A kind of purple potato condensed milk is prepared according to the following method:

[0056] (1) Preparation of Purple Potato Additives

[0057] Take purple potato, carry out crushing, beating, and solid-liquid separation treatment to obtain purple potato slurry and purple potato residue, add purple potato residue to 4 times the amount of dilute hydrochloric acid solution with pH value of 3, and at 45 ° C temperature Ultrasonic extraction was carried out for 20 minutes, and then filtered to obtain an extract. The pH value of the extract was adjusted to 6 with 0.1 mol / L potassium hydroxide solution, dried into powder, mixed with purple potato slurry, stirred evenly, and passed through a 100-mesh sieve. Filter, finally add tea polyphenols, sodium guanylate and malic acid, the addition amount of tea polyphenols is 0.008%, the addition amount of sodium guanylate is 0.2%, the addition amount of malic acid is 0.15%, and the temperature is 30 ℃. Let stand f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap