Connection device and lifting mechanism

A technology of connecting device and lifting shaft, which is applied in the directions of conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of the maximum height of the lifting shaft being not adjustable, and achieve the effect of improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

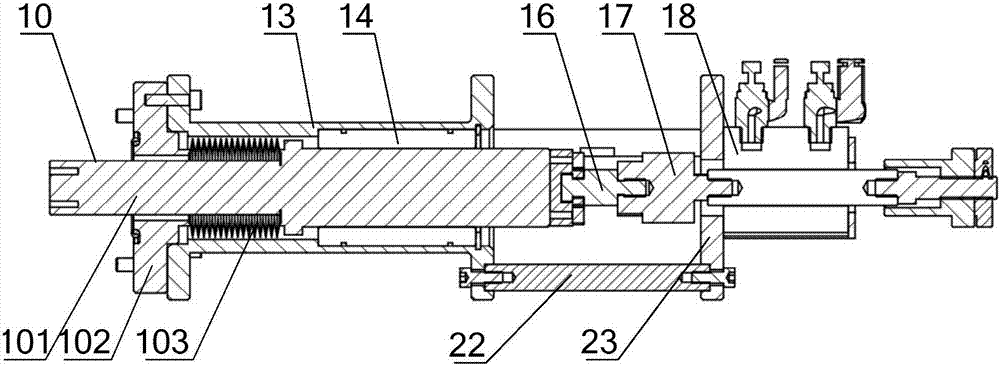

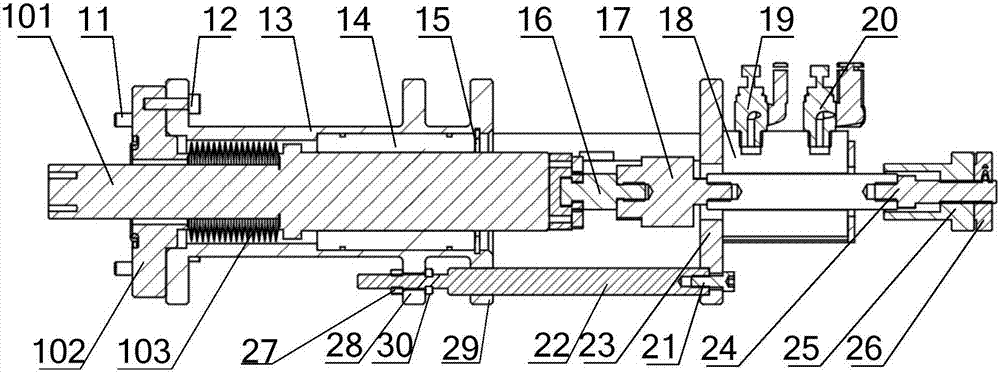

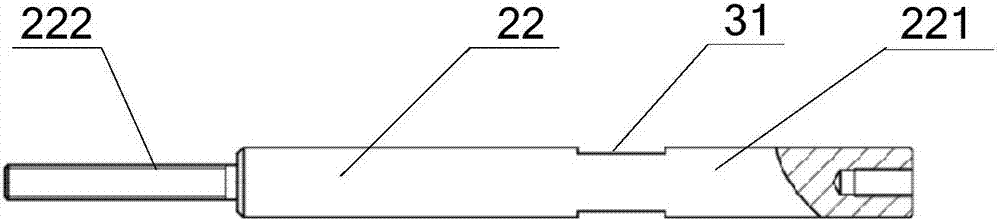

[0039] The technical solutions in the present invention will be clearly and completely described below with reference to the accompanying drawings of the present invention. Obviously, the described embodiments are a part of the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

[0040] By improving the structure and connection of the connecting column and the linear bearing sleeve, the invention realizes that the use length of the connecting column can be flexibly adjusted, can overcome the errors introduced by the processing and assembly of parts, and realize the pick-and-place process position and the degassing or annealing process position. accurate positioning, and can be used with different types of heating components to improve the extensive use.

[0041] Combi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap