Process for preparing gelatin through enzyme method

An enzymatic preparation and gelatin technology, applied in biochemical equipment and methods, enzymology/microbiology devices, enzyme production/bioreactors, etc., can solve the problems of high fluctuation, high cost, material leakage, etc. The effect of reducing, reducing the number of labor, and reducing the cost of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The technical scheme of the present invention will be described in detail below with reference to the drawings and specific embodiments.

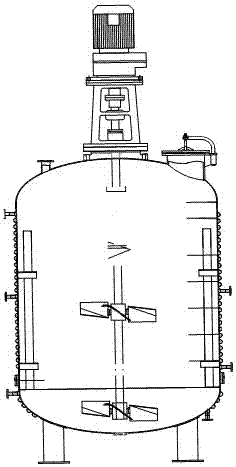

[0025] Such as figure 1 As shown, the gelatin extraction process for the industrial production of gelatin used in the production of capsules by the biological enzyme method, after the bone meal is put into the gelatin extraction pot, add water to raise the temperature to 40-70°C (the ratio of water to material to liquid is 1:3.5), and the pH value is adjusted to 2-11 , Add enzyme for 1-10 hours to extract the gum solution, then adjust the PH value to 2-10, after 1-3 hours, adjust the pH value of the gum solution to 5.5-6.5, and then coarsely filter the gelatin liquid and solid residue , Fine filtration, concentration, sterilization, drying and crushing to obtain gelatin products.

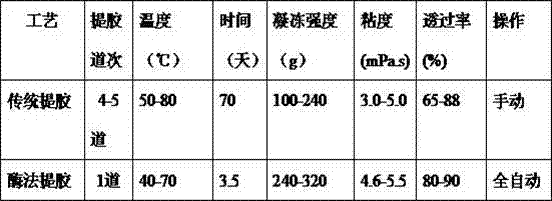

[0026] Comparison table of traditional crafts and new crafts

[0027]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap