Door hinge fixing plate connecting structure

A technology for connecting structure and fixing plate, applied in the direction of folding plate, door/window fittings, building structure, etc., can solve the problem of door hinge fixing screw holes being easily damaged, and achieves easy falling off, simple installation, and guaranteed stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

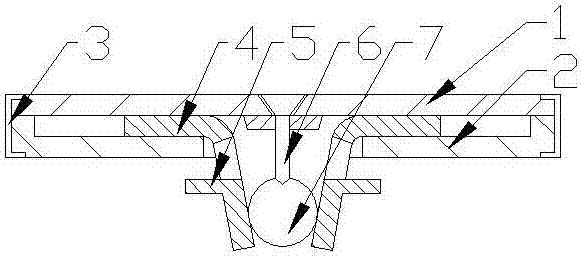

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] Such as figure 1 As shown, the present invention is a door hinge fixed plate connection structure, including an upper splint and a lower splint fixedly connected to each other, a fixed interlayer is arranged between the upper splint and the lower splint, and two mirror-symmetrical arrangements are arranged in the fixed interlayer. Clamping plate, the clamping plate is arc-shaped, one end of the clamping plate is clamped in the fixed interlayer, an opening is arranged in the middle of the lower clamping plate, and the other end of the clamping plate extends to the outside of the fixed interlayer through the opening ; A number of turning protrusions are arr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap