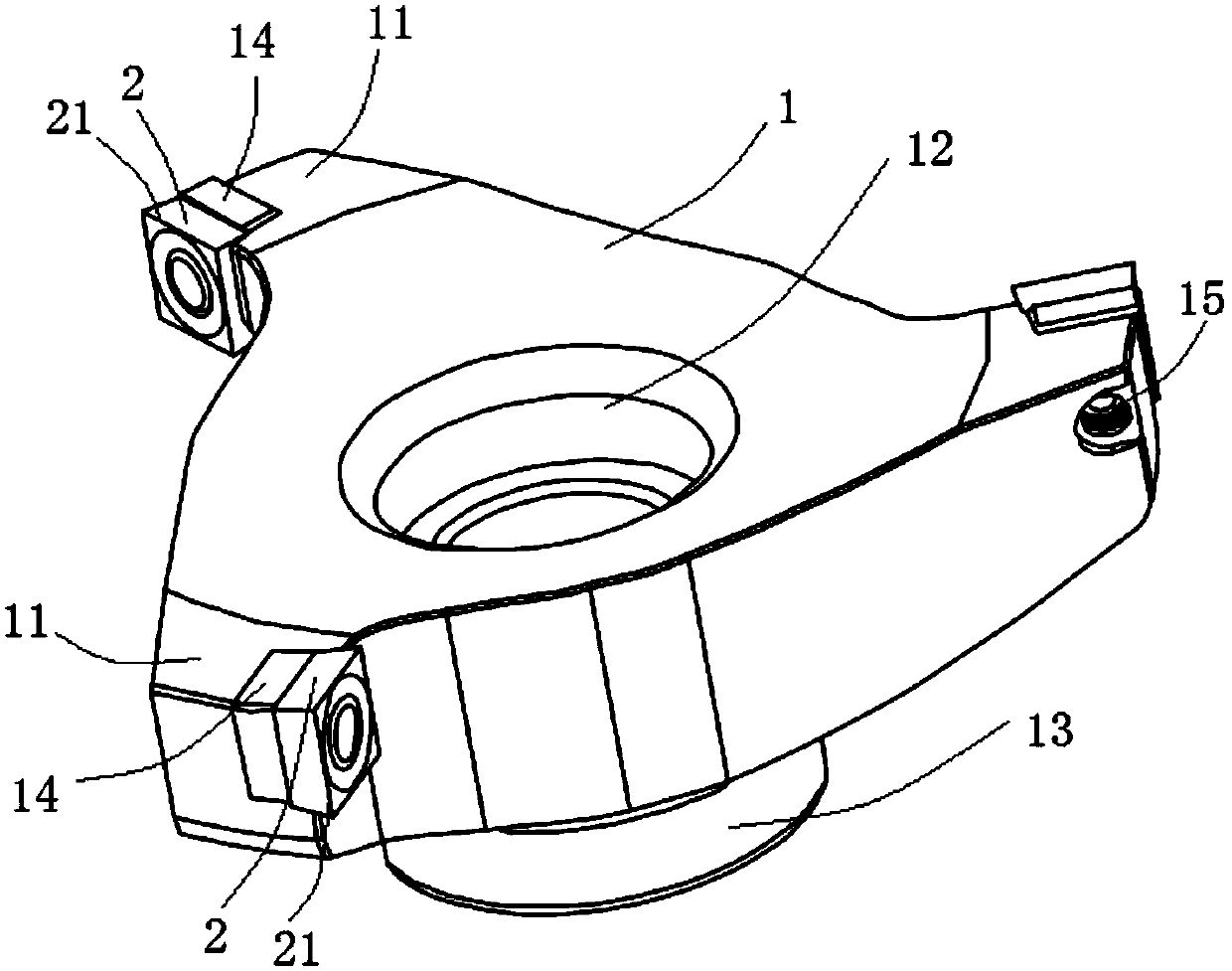

Three-claw cutter head

A technology of cutter head and cutter holder, which is applied to milling cutters, attachments of cutter holders, tools for lathes, etc., can solve problems such as troubles, and achieve the effect of convenient clamping and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The following will be attached figure 1 The present invention is described in detail: the present invention includes a knife holder 1 and a blade 2. The knife holder 1 is a revolving structure. The edge of the knife holder 1 is protruded with three equally distributed brackets 11, and the three The bracket 11 is inclined counterclockwise around the tool holder 1; the center of the tool holder 1 is provided with a mounting hole 12, and a clamping body 13 penetrating the mounting hole 12 is installed on one side of the tool holder 1, through which The clamping body 13 and the mounting hole 12 install the tool holder 1 on the processing equipment; the blade 2 is fixed on the mounting frame 14 provided by the three brackets 11, and arranged in a counterclockwise direction, and the blade 2 The knife edge 21 is higher than the upper plane and the outer side of the tool holder 1; the protruding size of the bracket 11 of the three-jaw cutter head can be set according to the diamete

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap