Mie resonance anti-counterfeiting product based on hollow structure blue TiO2 and anti-counterfeiting method of Mie resonance anti-counterfeiting product

A hollow structure and product technology, applied in the direction of nanotechnology, titanium oxide/hydroxide, instruments, etc., can solve the problems that users are not easy to identify, cannot distinguish the authenticity, and the anti-counterfeiting marks are easy to be counterfeited, so as to meet the anti-counterfeiting requirements and easily Resolve and overcome the effect of complex preparation and small scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

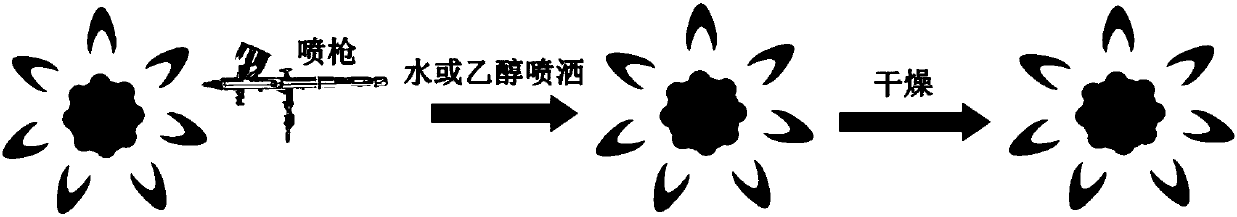

Method used

Image

Examples

Embodiment 1

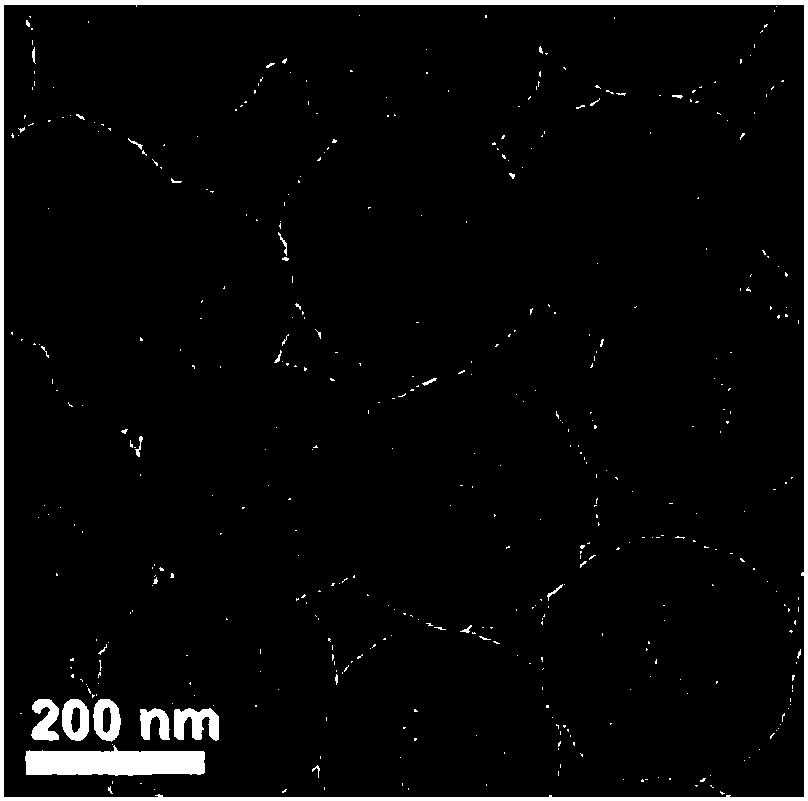

[0034] A monodisperse blue TiO with hollow structure 2 The preparation method of material comprises the following steps:

[0035] Step 1, a certain amount of tetraethyl orthosilicate is mixed with absolute ethanol and deionized water and stirred evenly, the volume ratio of ethanol to tetraethyl orthosilicate is 26:1, deionized water and tetraethyl orthosilicate The volume ratio is 5:1;

[0036] Step 2, add a certain amount of concentrated ammonia water (concentration 26-28wt%) to step 1, the volume ratio of concentrated ammonia water to tetraethyl orthosilicate is 0.75:1, and centrifuge, wash and separate after stirring for 4 hours;

[0037] Step 3, the SiO obtained in step 2 2 Dispersed in an appropriate amount of absolute ethanol for subsequent use, the volume ratio of the volume of absolute ethanol to tetraethyl orthosilicate described in step 1 is 23:1;

[0038] Step 4, to the SiO in step 3 2 Add a certain volume of acetonitrile and an appropriate amount of hydroxypropyl

Embodiment 2

[0046]A monodisperse blue TiO with hollow structure 2 The preparation method of material comprises the following steps:

[0047] Step 1, mix and stir a certain amount of tetraethyl orthosilicate with absolute ethanol and deionized water, the volume ratio of ethanol to tetraethyl orthosilicate is 20:1, deionized water and tetraethyl orthosilicate The volume ratio is 4:1;

[0048] Step 2, add a certain amount of concentrated ammonia water (concentration 26-28%) to step 1, the volume ratio of concentrated ammonia water to tetraethyl orthosilicate is 0.77:1, centrifuge and wash and separate after stirring for 4 hours;

[0049] Step 3, the SiO obtained in step 2 2 Dispersed in an appropriate amount of absolute ethanol for subsequent use, the volume ratio of the volume of absolute ethanol to tetraethyl orthosilicate described in step 1 is 23:1;

[0050] Step 4, to the SiO in step 3 2 Add a certain volume of acetonitrile and an appropriate amount of hydroxypropyl cellulose to the su

Embodiment 3

[0058] A monodisperse blue TiO with hollow structure 2 The preparation method of material comprises the following steps:

[0059] Step 1, mix and stir a certain amount of tetraethyl orthosilicate with absolute ethanol and deionized water, the volume ratio of ethanol to tetraethyl orthosilicate is 25:1, deionized water and tetraethyl orthosilicate The volume ratio is 6:1;

[0060] Step 2, add a certain amount of concentrated ammonia water (concentration 26-28%) to step 1, the volume ratio of concentrated ammonia water to tetraethyl orthosilicate is 0.73:1, centrifuge and wash and separate after stirring for 4 hours;

[0061] Step 3, the SiO obtained in step 2 2 Dispersed in an appropriate amount of absolute ethanol for subsequent use, the volume ratio of the volume of absolute ethanol to tetraethyl orthosilicate described in step 1 is 23:1;

[0062] Step 4, to the SiO in step 3 2 Add a certain volume of acetonitrile and an appropriate amount of hydroxypropyl cellulose to the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap