Wood grain machine and control method thereof

A wood grain machine and wood grain technology, applied in the field of imprinting machines, can solve the problems of slow imprinting operation speed and poor positioning, and achieve the effect of increasing line speed and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

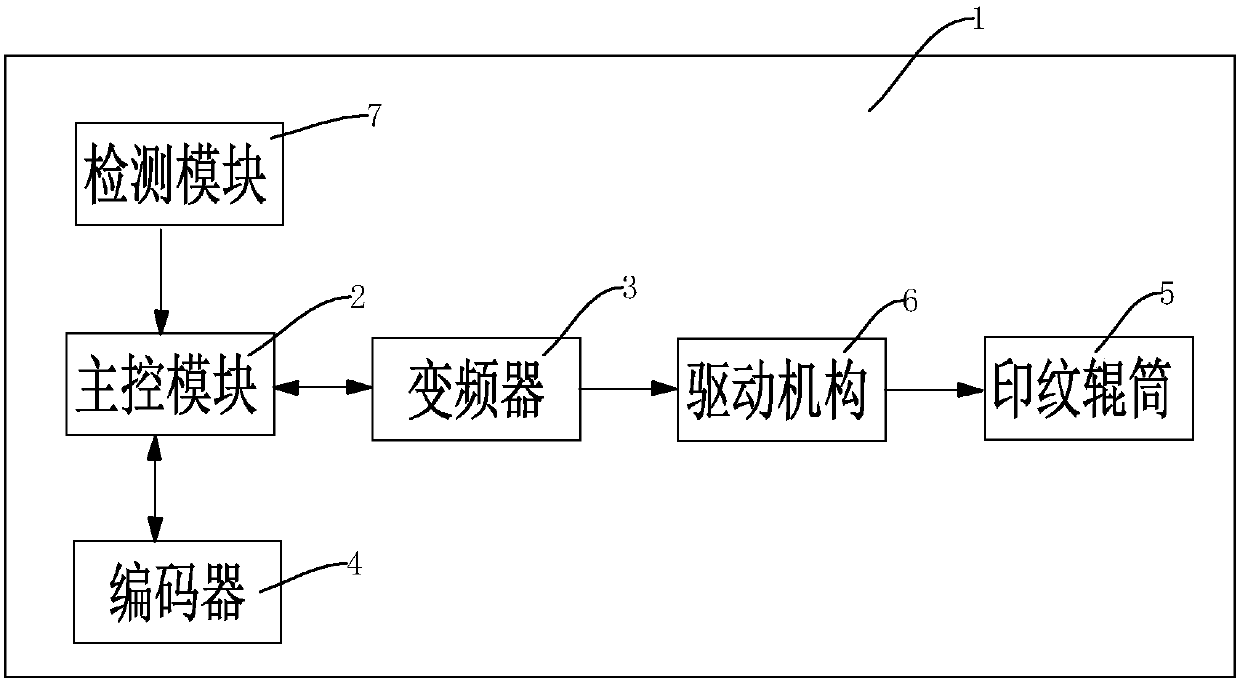

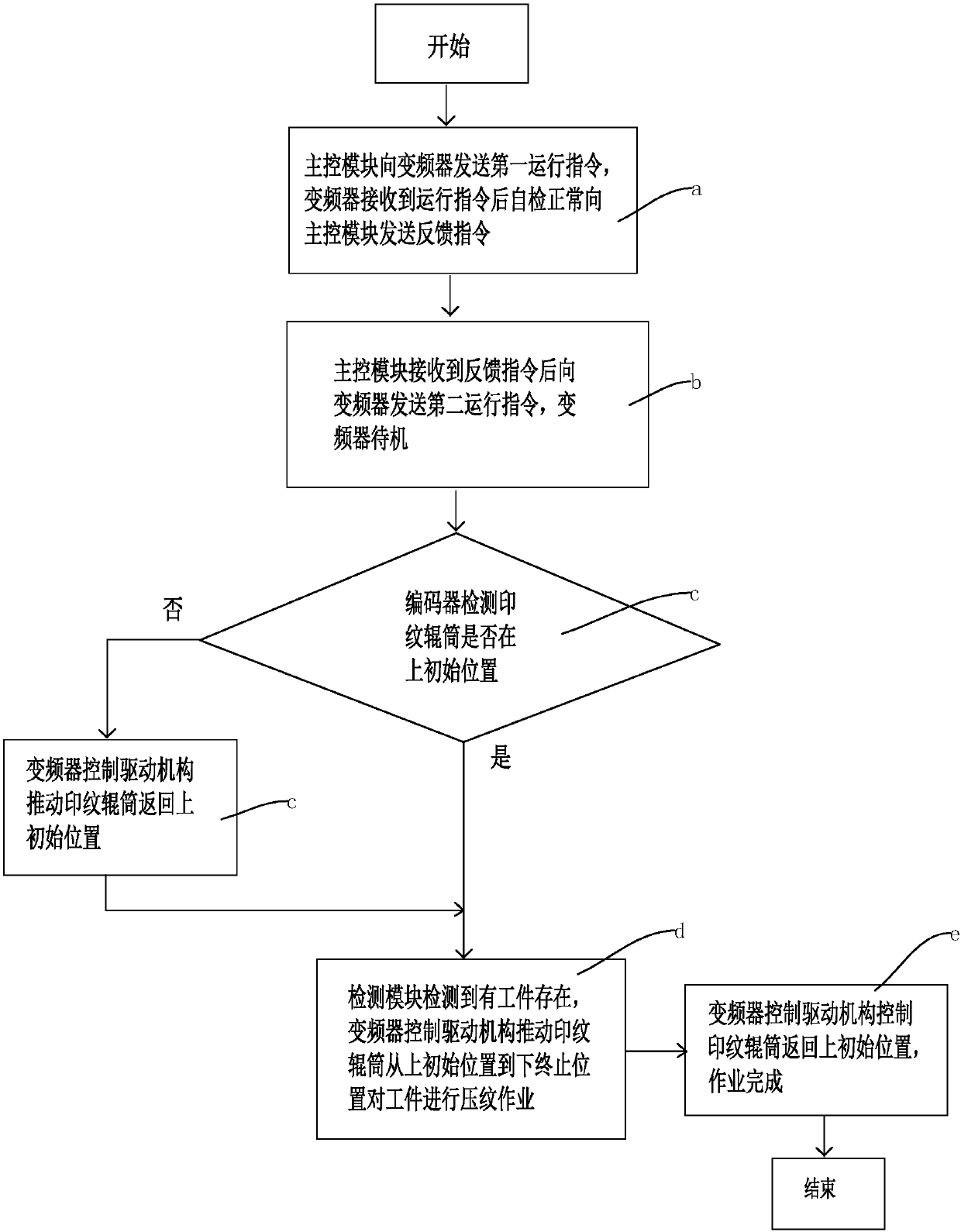

[0018] Such as figure 1 As shown, a wood grain machine includes a wood grain machine body 1, and the wood grain machine body 1 is provided with a main control module 2, a frequency converter 3, an encoder 4, an embossing roller 5 and a driving embossing roller 5 The driving mechanism 6 that moves up and down, the frequency converter 3 is electrically connected with the main control module 2 and the driving mechanism 6 respectively, and the encoder 4 is electrically connected with the main control module 2 for setting the printing cylinder 5 up and down The upper initial position and the lower end position of the motion. The present invention can perform precise positioning through the encoder 4, so that the embossing roller 5 can position and emboss the workpiece of any profile. The embossing process of this design is from top to bottom, and the vertical embossing method is adopted, which improves the embossing operation. Line speed, improve work efficiency.

[0019] The wood g

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap