Mining method for dunn-bass-containing steeply-inclined thin ore vein groups

A mining method and technology for thin ore veins, which are applied in the mining field of steeply inclined thin ore vein groups/groups with rock inclusions, can solve the problems of difficulty in multi-layered rock-incorporation mining, the shape of steeply inclined thin ore veins, etc., so as to avoid the mixing of waste rock. , the effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A tungsten deposit in Northwest China is a black tungsten deposit. The ore body is re-existed in the quartzite. The boundary of the ore rock can be distinguished with the naked eye (the ore body is black and the quartzite is white). The ore body is a steeply inclined ore body with a dip angle of 55°-75°; The ore body is produced in layers with complex thickness variations. Part of the interlayer-containing vein group adopts the mining method of a kind of steeply inclined thin-vein group / group containing interlayer rock according to the present invention, and the production capacity of the stope is about 45-55t / d.

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

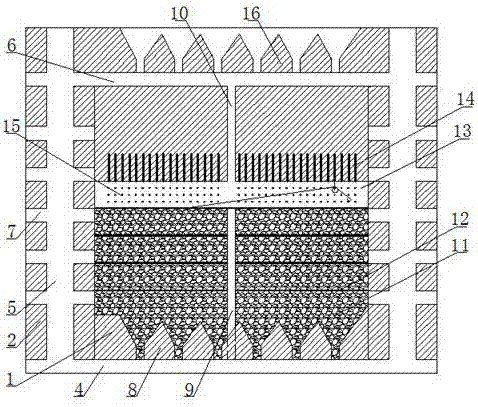

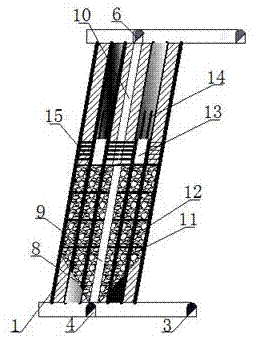

[0018] Such as Figure 1-2 Shown, the mining method of the present invention's steeply inclined thin vein group / group containing intercalated stones is implemented in this mine as follows:

[0019] Structural parameters o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap