Converter for converting oil heating into water heating

A technology of heat converter and heat energy conversion, which is applied in household heating, heating fuel, heating methods, etc. It can solve the problems of energy waste, single energy sharing, and inability to make full use of heat energy resources, etc., and achieves wide application range, production and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

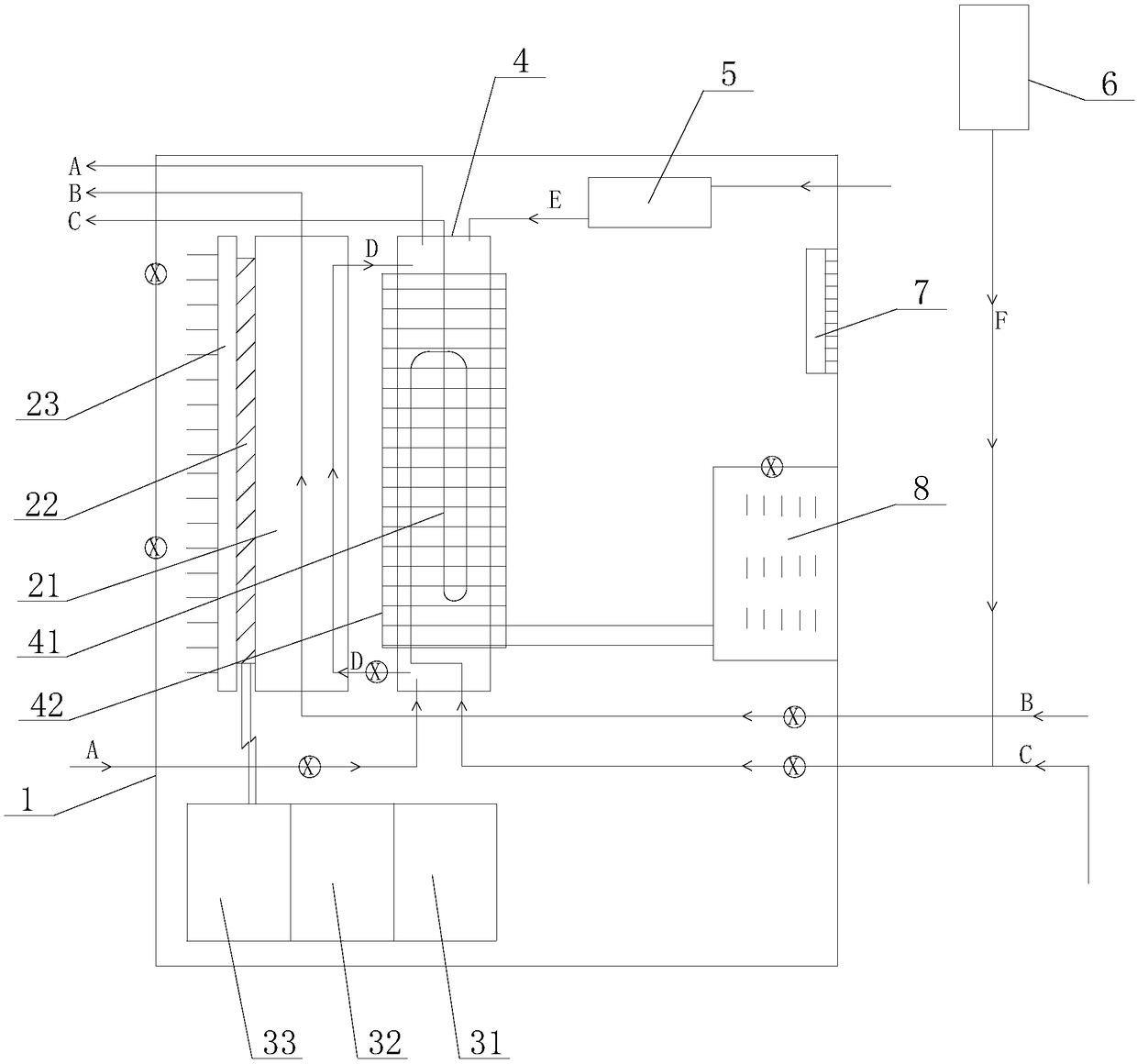

[0015] Reference figure 1 , The oil-heat-to-water heating and heating converter of this embodiment includes a box-shaped housing 1 and an electromagnetic heating device 8 arranged in the housing 1, a thermal energy conversion device, a waste heat power generation device and a device for controlling the electromagnetic heating 8 working smart controller 7.

[0016] The thermal energy conversion device includes a closed heat conduction oil heating box 4, a heat exchange coil 41 arranged in the heat conduction oil heating box 4, and an electromagnetic coil 42 wound on the outer wall of the heat conduction oil heating box 4. The electromagnetic coil 42 is connected and Controlled by the electromagnetic heating device 8; the waste heat power generation device includes an oil heat conversion box 21, a power generation module 21 fixed on the outer side wall of the oil heat conversion box 21, a rectifier module 33 electrically connected to the power generation module, and a conversion boost

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap