Method for replacing oil inlet pipe of crane

A replacement method and crane technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the joint body 1 is difficult to unscrew, reduce the replacement efficiency of the oil inlet pipe 4, and affect the replacement efficiency of the oil inlet pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

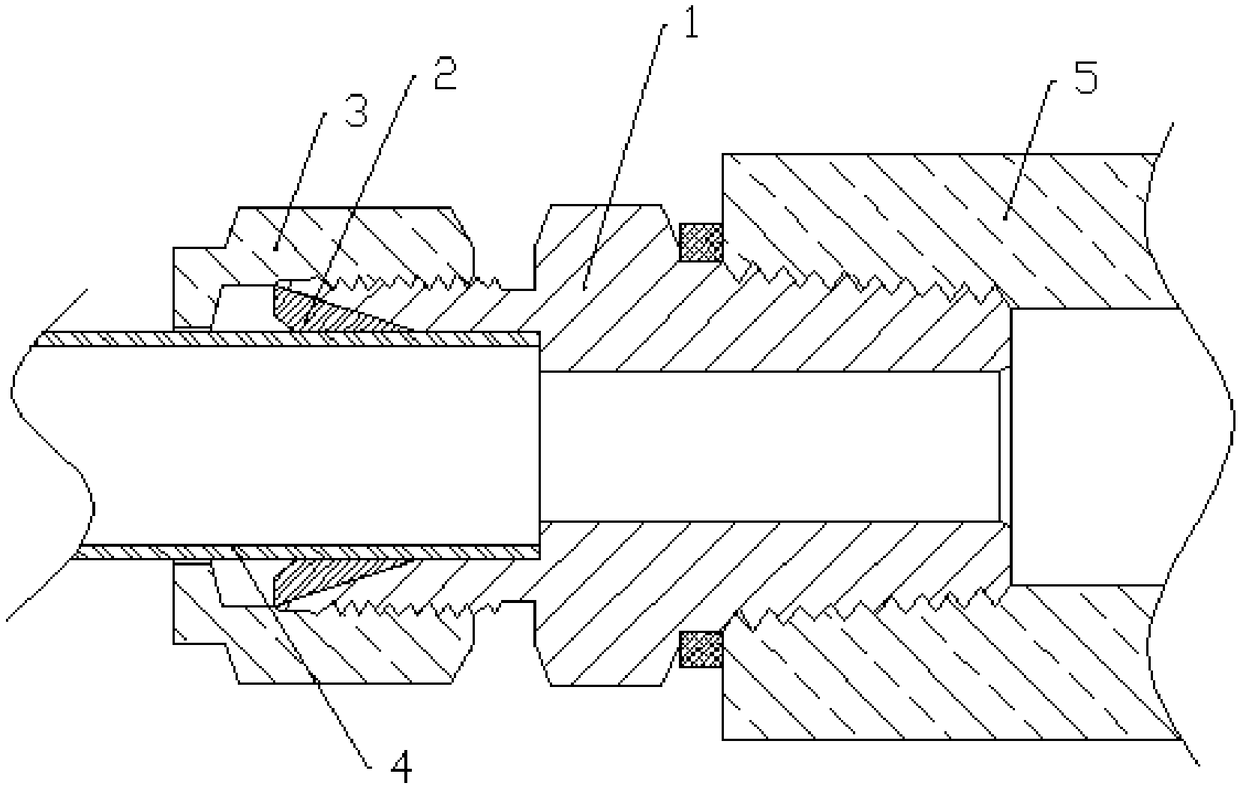

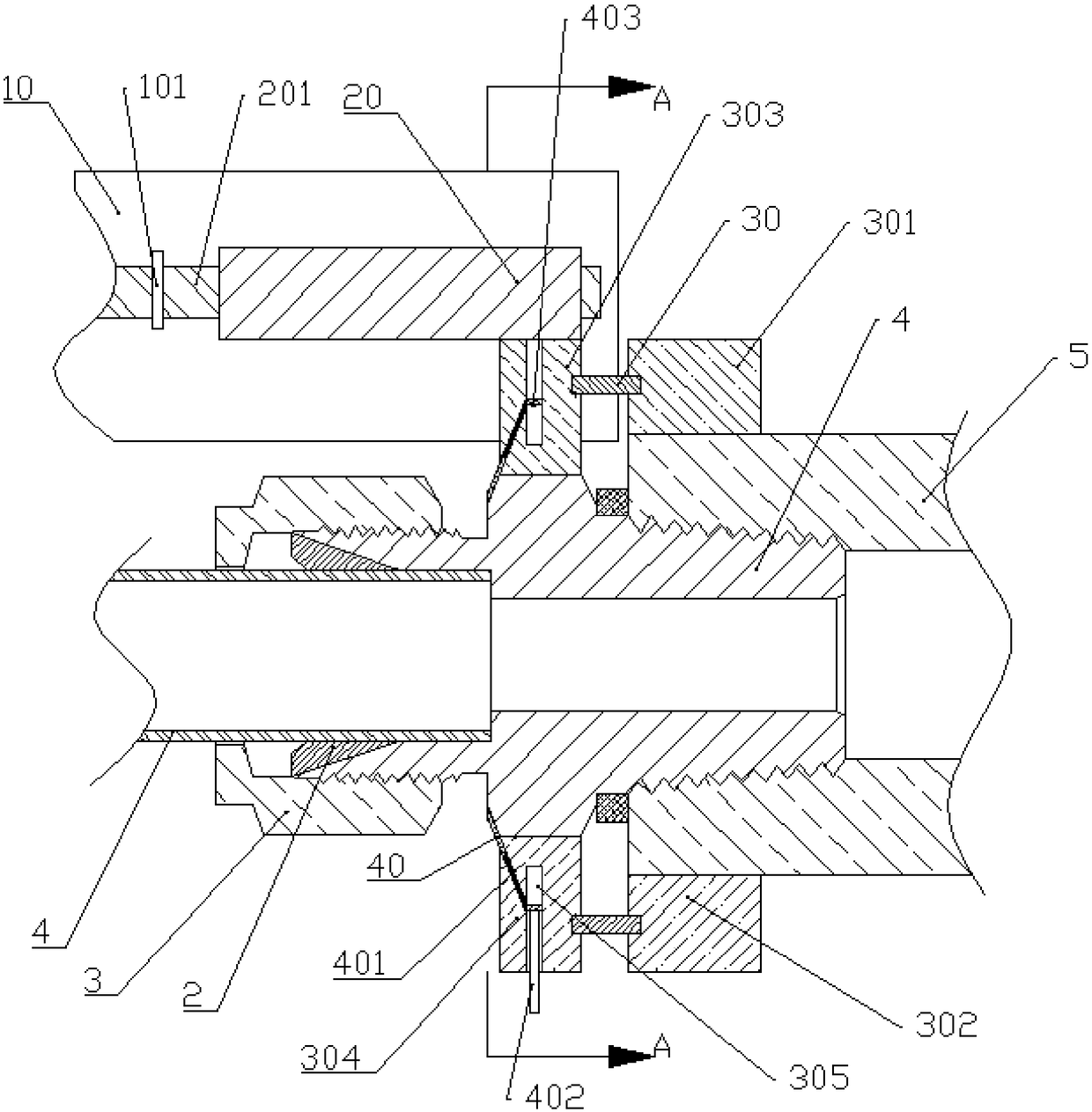

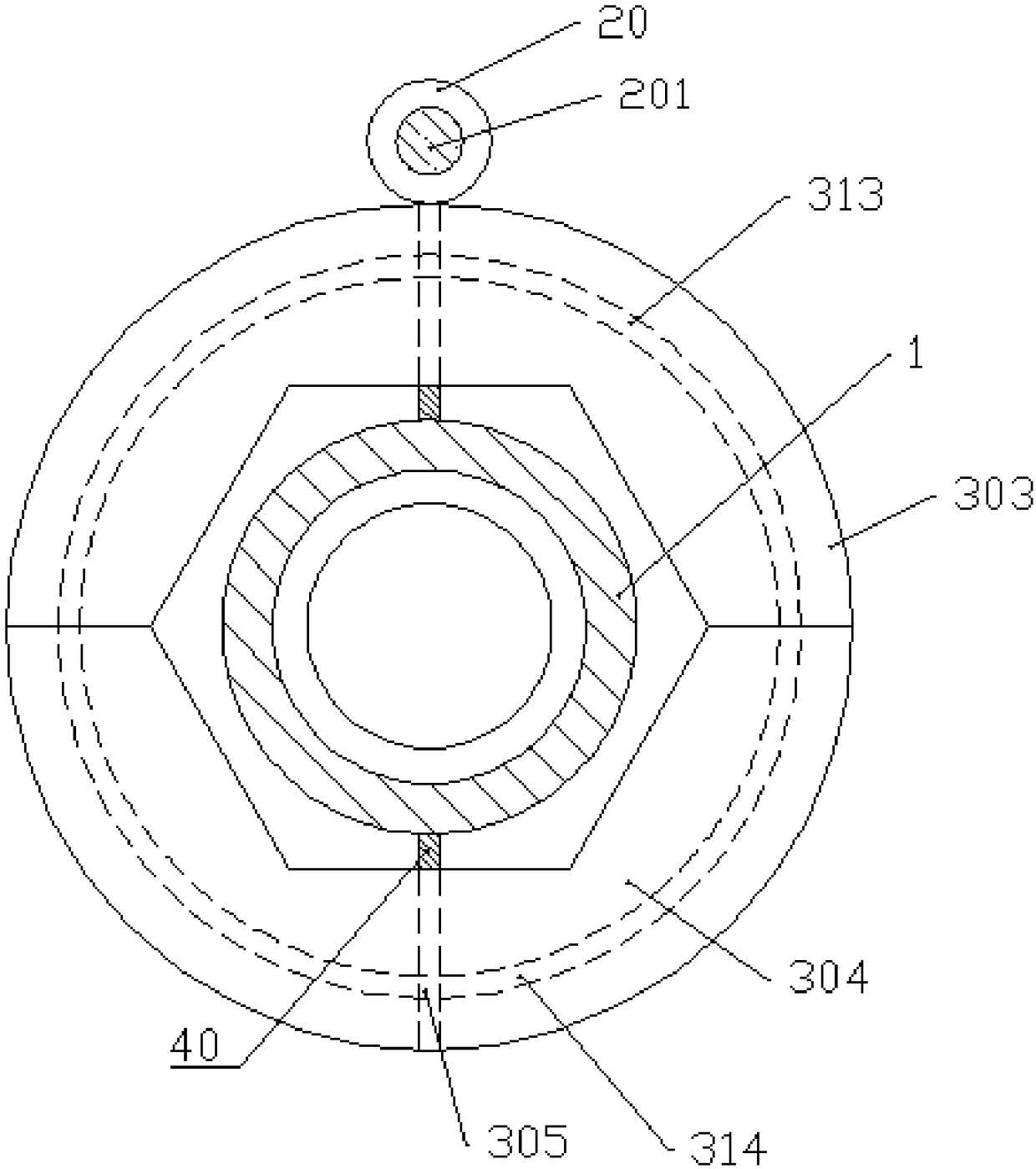

[0021] The reference signs in the accompanying drawings of the specification include: joint body 1, joint head 5, support frame 10, support ring 101, stud 20, screw rod 201, spring rod 30, first fixed block 301, first annular groove 311, second Two fixed blocks 302, the second annular groove 312, the first rotating block 303, the third annular groove 313, the second rotating block 304, the fourth annular groove 314, the vertical groove 305, the baffle plate 40, the pull bar 401, the insertion rod 402 . Skateboard 403 .

[0022] This method comprises the following steps:

[0023] Step 1: mark the joint body to be replaced on the crane as the first joint body 1; mark the joint body on the new oil inlet assembly as the second joint body 1.

[0024] Step 2: Prepare the replacement unit, basically as attached figure 2 , attached image 3 And attached Figure 4 As shown, it includes a support frame

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap