Offshore installation buffer device

A buffer device and buffer pad technology are applied in the field of offshore installation of buffer devices and soft landing systems, which can solve the problems of self-heavy wind turbine body, economic loss, wind turbine damage, etc., and achieve the effects of simple structure, smooth and soft landing, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

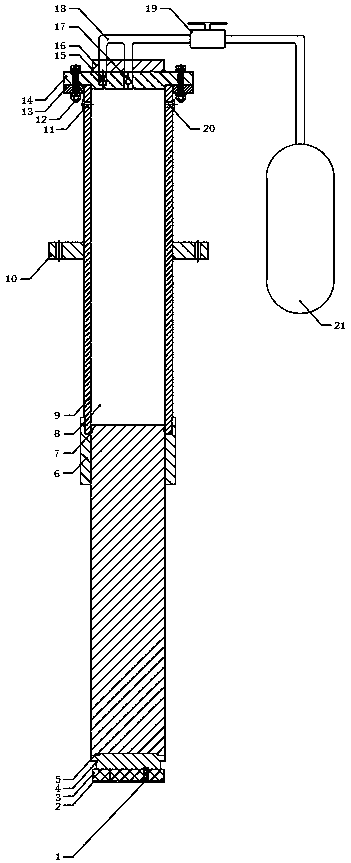

[0025] Example 1: see figure 1 , The buffer device installed on the offshore wind power generator includes three parts: a plunger assembly, a cylinder block assembly and an energy storage assembly. The cylinder assembly is sleeved on the outside of the plunger assembly to form an inner cavity, the plunger inner cavity communicates with the external oil pipe through the speed regulating valve and the one-way valve, and the energy storage assembly is connected to the oil pipeline in the cylinder through the interface of the upper end cover of the cylinder. The accumulator is charged with an inert gas (such as nitrogen) with a certain pressure.

[0026] Plunger assembly: Nylon pad and buffer pad are at the bottom of the structure, which is the contact surface with the offshore foundation platform; the buffer pad is connected to the lower end cover of the plunger through bolts; the lower end cover is welded to the inner surface of the cylinder to achieve closure; the two sides of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap