PVC film raw material composition and PVC automobile waterproof film

A raw material composition and waterproof membrane technology, applied in the field of PVC film, can solve the problems of heavy odor, achieve the effect of improving environmental performance and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

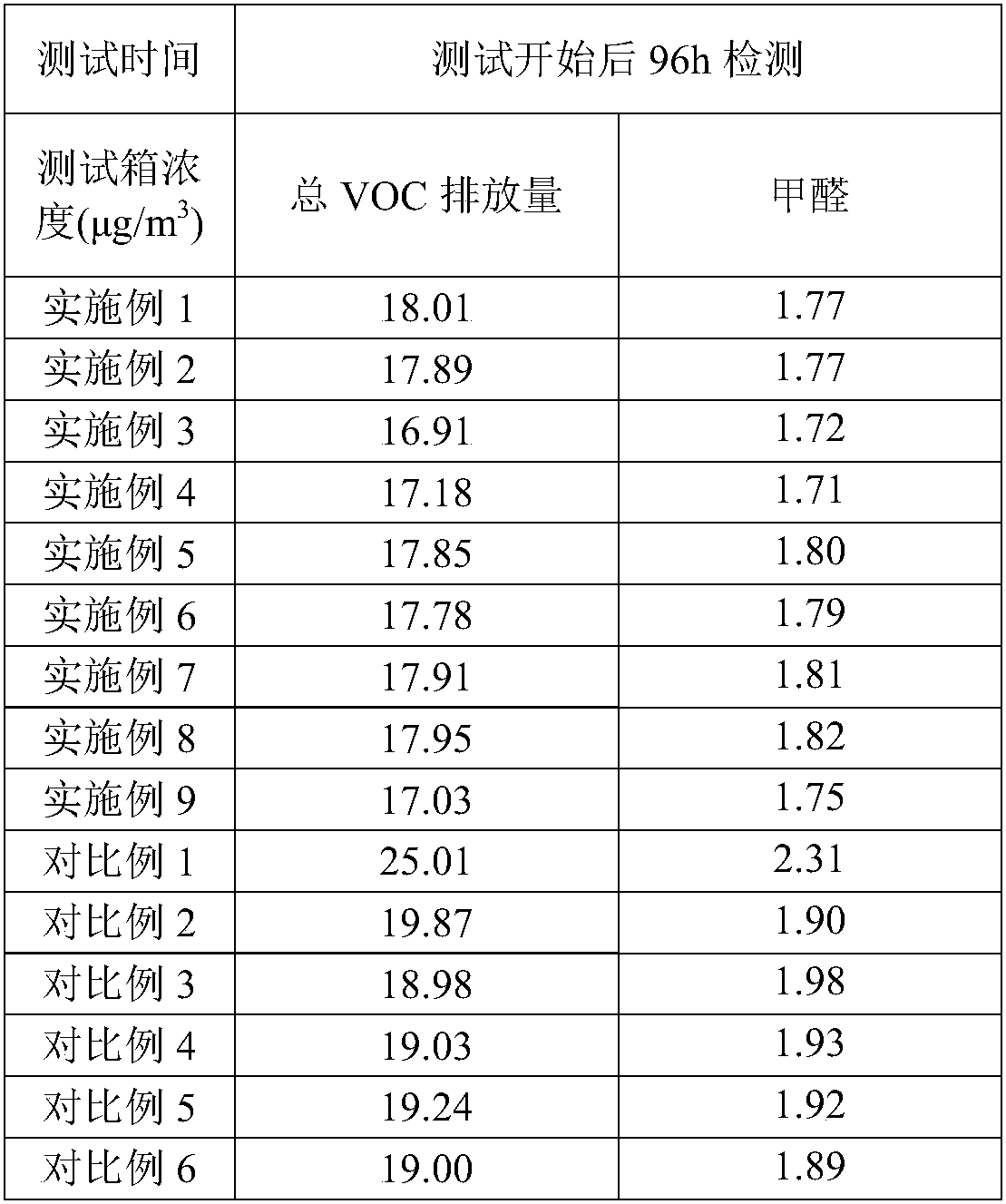

[0025] The preparation method of the above-mentioned PVC automobile waterproof membrane adopts the above-mentioned improved PVC automobile waterproof membrane formula that replaces the liquid flame retardant with a powder flame retardant and reduces the amount of flame retardant, and adds a powder flame retardant at a specific time In combination, after the initial mixing at a relatively low speed, and then high-speed stirring for a specific time, then add the flame retardant for mixing, so that the flame retardant can be evenly mixed with other raw materials, so that the prepared The odor of PVC automotive waterproofing film is greatly reduced, and the environmental protection performance is improved.

[0026] In the above preparation method, the first stirring speed and the second stirring speed can be obtained by using the existing stirring speed of mixing and stirring, or can be obtained by improving the existing stirring speed. In a preferred embodiment of the present applic

Embodiment 1

[0040] Put 100 parts of PVC, 30 parts of DIDP plasticizer and 1 part of powdered calcium-zinc stabilizer in a mixer for mixing, and first mix at a speed of 200rpm for 30s to obtain an initial mixture; then increase the speed to Mix at 700rpm for 220s, then add 0.1 part of powder flame retardant (model: LM-NPP8081) to the mixture, and continue mixing at this speed for 400s to obtain a remix;

[0041] Let the remixed material pass through the internal mixer and rolling mill in turn, and control the plasticizing temperature in the rolling mill to 165°C to obtain a plastic compound;

[0042] The plastic compound is sent to a five-roll calender for calendering to obtain a PVC automotive waterproof film; among them, the temperature of the first three rollers is set to 175°C, the temperature of the fourth roller is 170°C, and the temperature of the fifth roller is 170°C. The temperature of the wheel was 150°C.

Embodiment 2

[0044] Put 100 parts of PVC, 50 parts of DIDP plasticizer and 6 parts of powdered calcium-zinc stabilizer in a mixer for mixing, and first mix at a speed of 500rpm for 10s to obtain a preliminary mixture; then increase the speed to Mix at 1000rpm for 180s. At this time, add 1.5 parts of powder flame retardant (model LM-NPP8081) to the mixture, and continue mixing at this speed for 300s to obtain a remix;

[0045] Let the remixed mixture pass through the internal mixer and rolling mill in turn, and control the plasticizing temperature in the rolling mill to 185°C to obtain a plastic compound;

[0046] Send the plastic compound into a five-roll calender for calendering to obtain a PVC automotive waterproof film; among them, the temperature of the first three rollers is set at 185°C, the temperature of the fourth roller is 178°C, and the temperature of the fifth roller The temperature of the wheel was 160°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap