CTS, CTP and die-cutting sample-making three-in-one plate-making machine

A three-in-one, plate-making machine technology, applied in the direction of printing plate preparation, printing, etc., can solve the problems of large tolerance, long time-consuming, low precision, etc., to achieve the effect of improving work efficiency and versatility, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] The main solution of the present invention is: the three-in-one plate-making machine of CTS, CTP, die-cutting proofing that the present invention proposes is mainly by installing one or more of the CTS laser head, CTP laser head, and die-cutting laser head Several types of laser head components, select the corresponding CTS laser head, CTP laser head, or die-cutting laser head according to the plate material, thereby improving the work efficiency and versatility of plate making and printing, and reducing production costs.

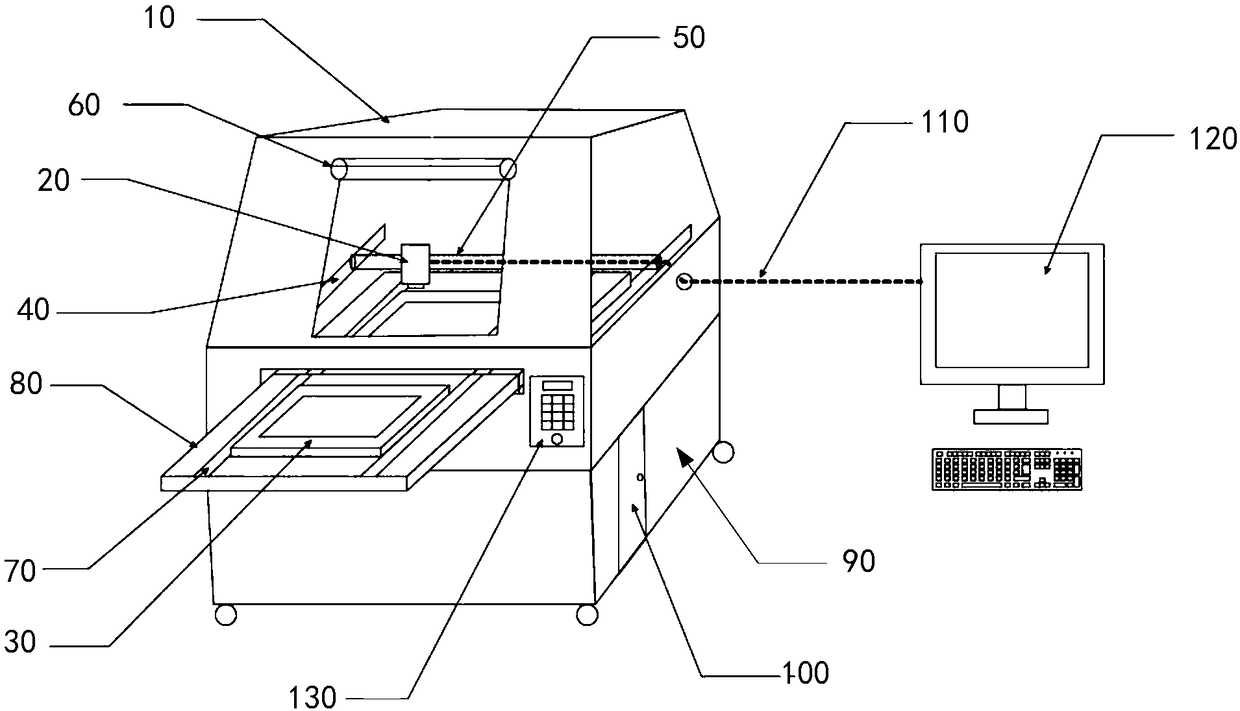

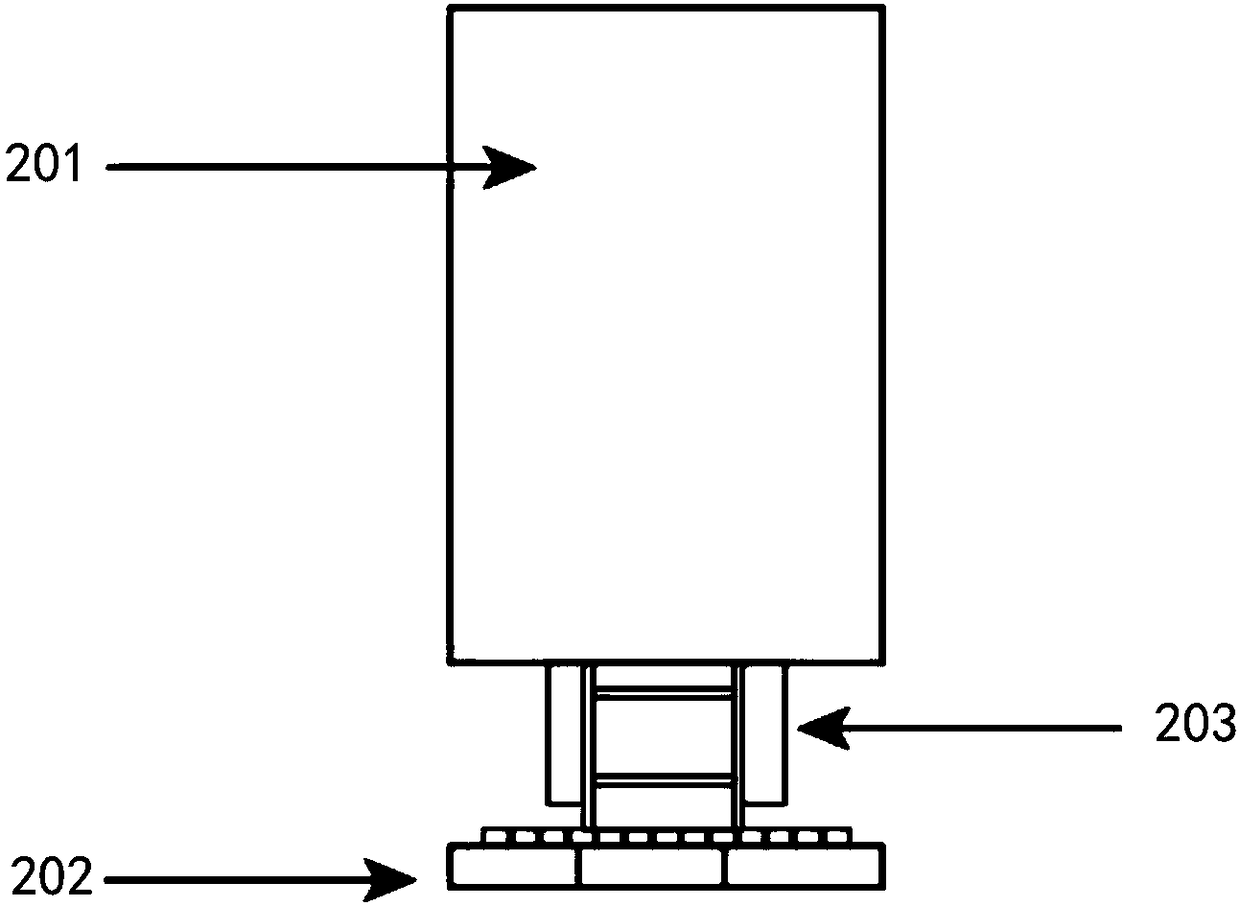

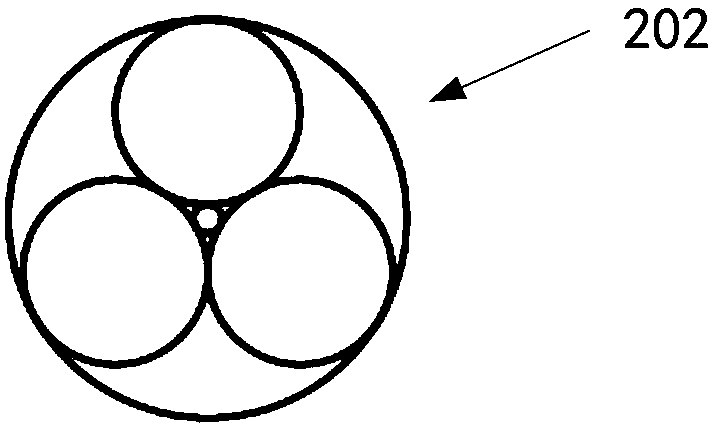

[0026] Specifically, please refer to Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the overall structure of a preferred embodiment of the CTS, CTP, die-cutting and proofing three-in-one plate-making machine of the present invention; figure 2 It is a structural schematic diagr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap