Method for recovery of tail pulp by delivering tail pulp into spherical boiler

A tailing pulp and pulp pump technology, applied in the field of papermaking, can solve the problems of inability to reuse in time, secondary pollution, and inability to reuse, and achieve the effect of saving drying and manual sorting costs and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be further described below in conjunction with embodiments.

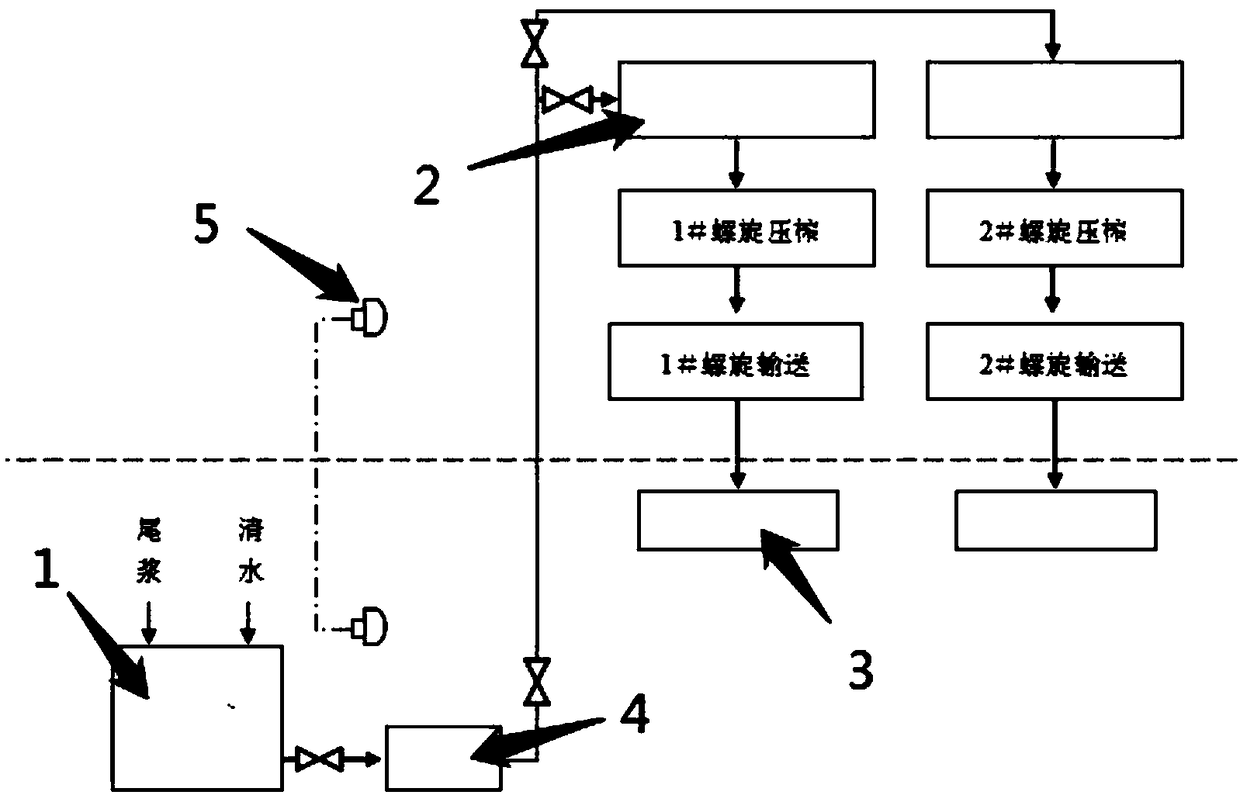

[0016] Such as figure 1 The tail slurry recycling method shown includes a tail slurry collection point for collecting tail slurry. The tail slurry collection point is the tail slurry collection point on the microfilter. The tail slurry collection point is installed at the tail slurry collection point to dilute the tail slurry. Tail slurry dilution tank 1. Connect the clear water inlet to the tail slurry dilution tank 1. The water inlet can be directly connected to tap water. The collected tail slurry is diluted with clean water. The dilution can be controlled as required. The dilution tank is equipped with a stirring device, manual stirring or machine stirring, there will be no precipitation after stirring, and it is more convenient when the slurry pump 4 transports the diluted tail slurry to the cyclone separator 2 through the slurry pump 4, and is separated by the cyclone The device 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap