Method for maintaining bearings of crane span structures of cutter suction dredgers

A cutter suction dredger and bearing technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of high unknown costs and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

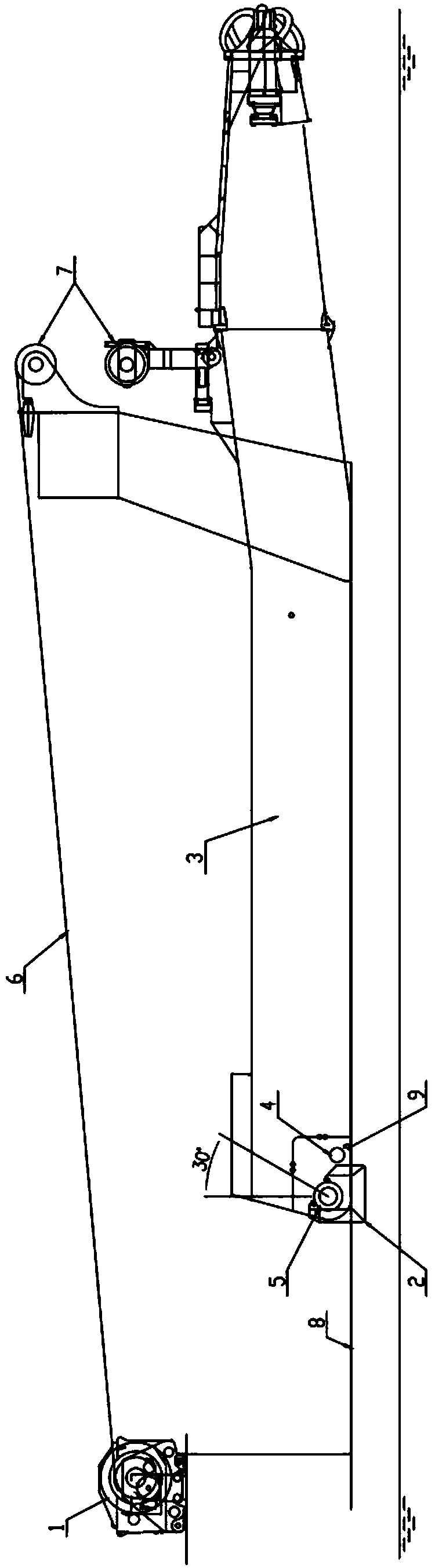

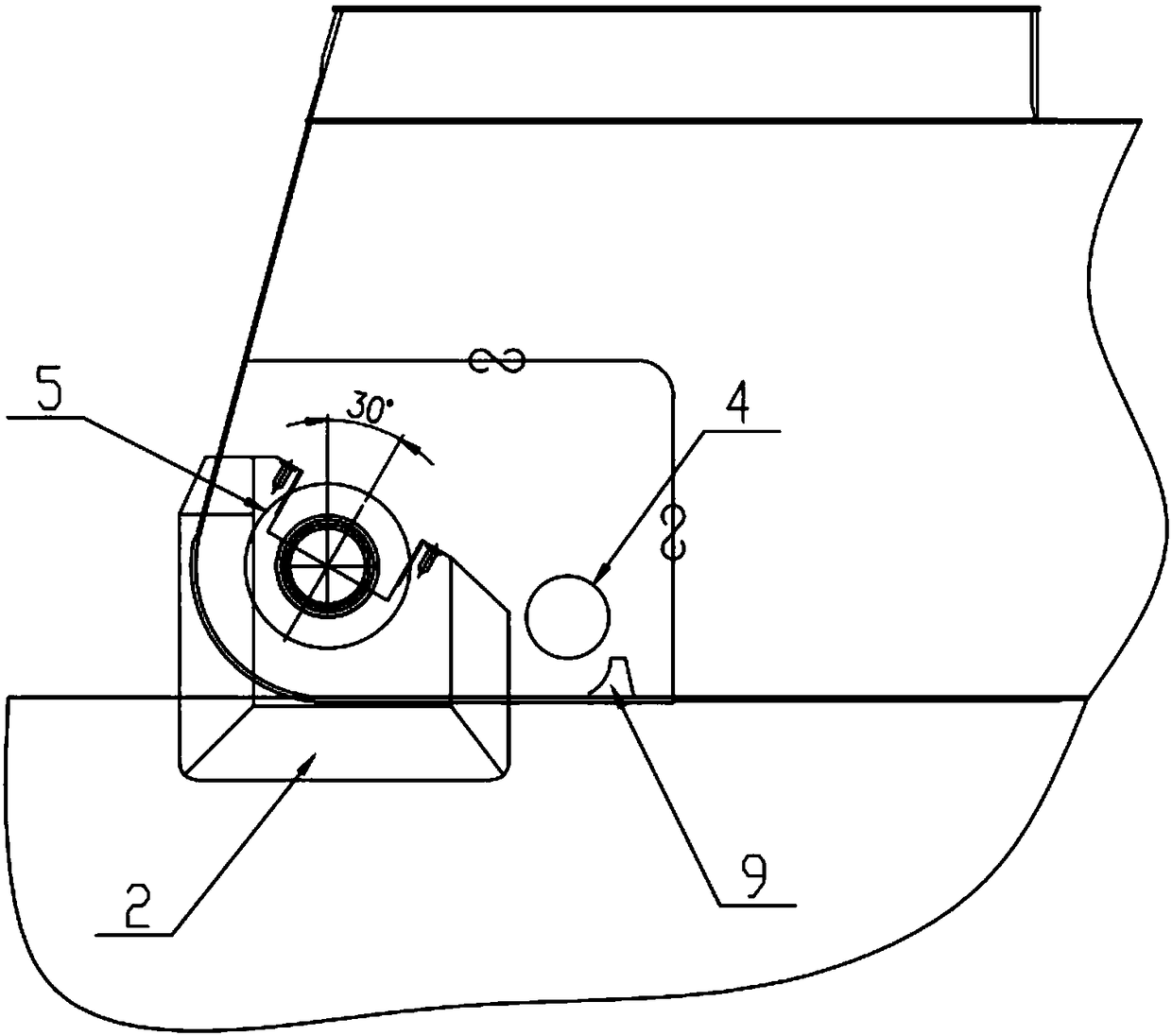

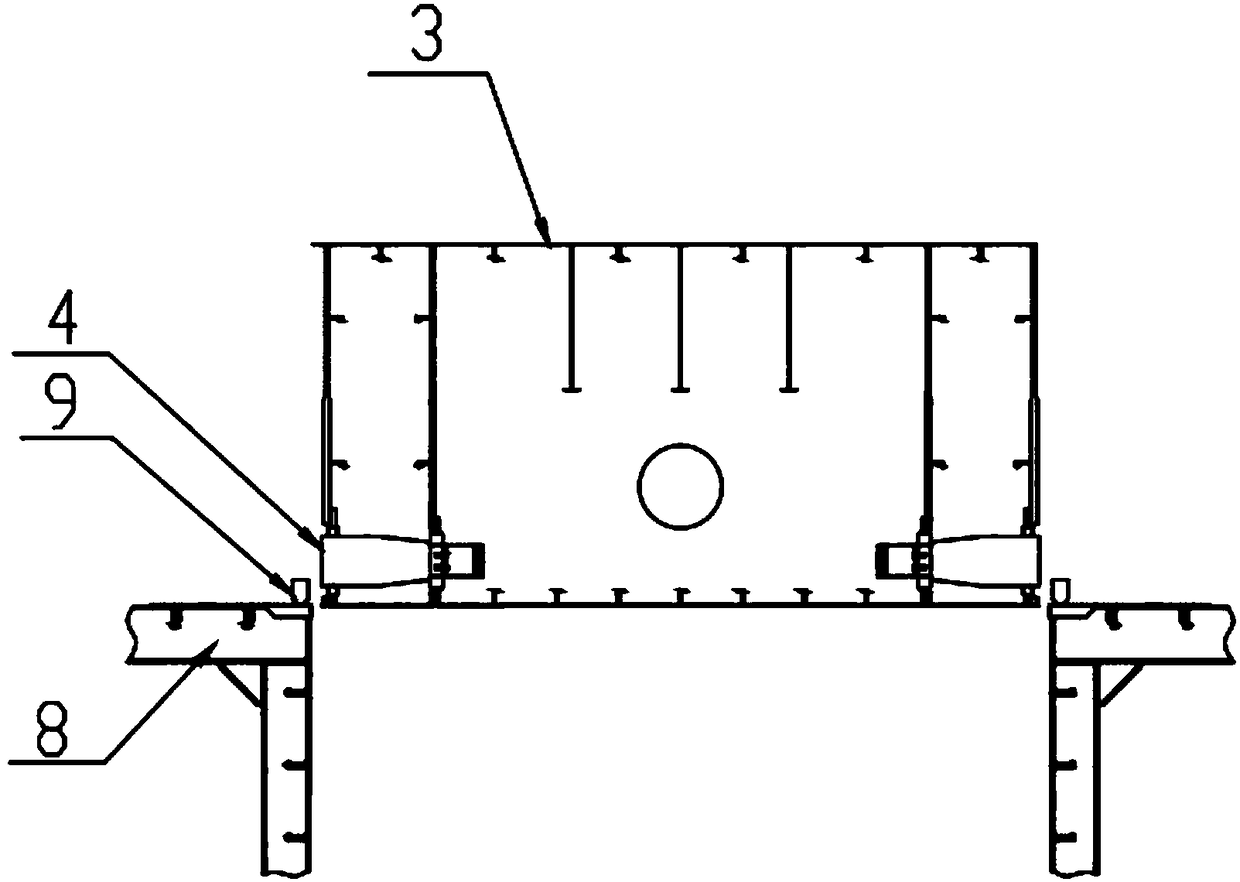

[0030] The embodiment of the present invention discloses a method for maintaining the bridge bearing of a cutter suction dredger. As shown in the figure, a bearing maintenance device (4) is installed on the original reamer bridge (3), and the bearing maintenance device (4) is cylindrical Shaped structure, with self-locking rotation function, the locking rotation adopts the form of installing a stopper at an appropriate position of the bearing maintenance device and fixing it with bolts; when it needs to be locked, install the stopper and fix it with bolts; when it needs to be removed, remove the bolt and fix it with bolts remove the block;

[0031] The bearing maintenance device (4) plays the role of supporting the reamer bridge (3)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap