Two-color mold sliding block taking-out mechanism

A technology of withdrawing mechanism and two-color mold, which is applied in the field of mold mechanism, and can solve problems affecting product appearance quality, product scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

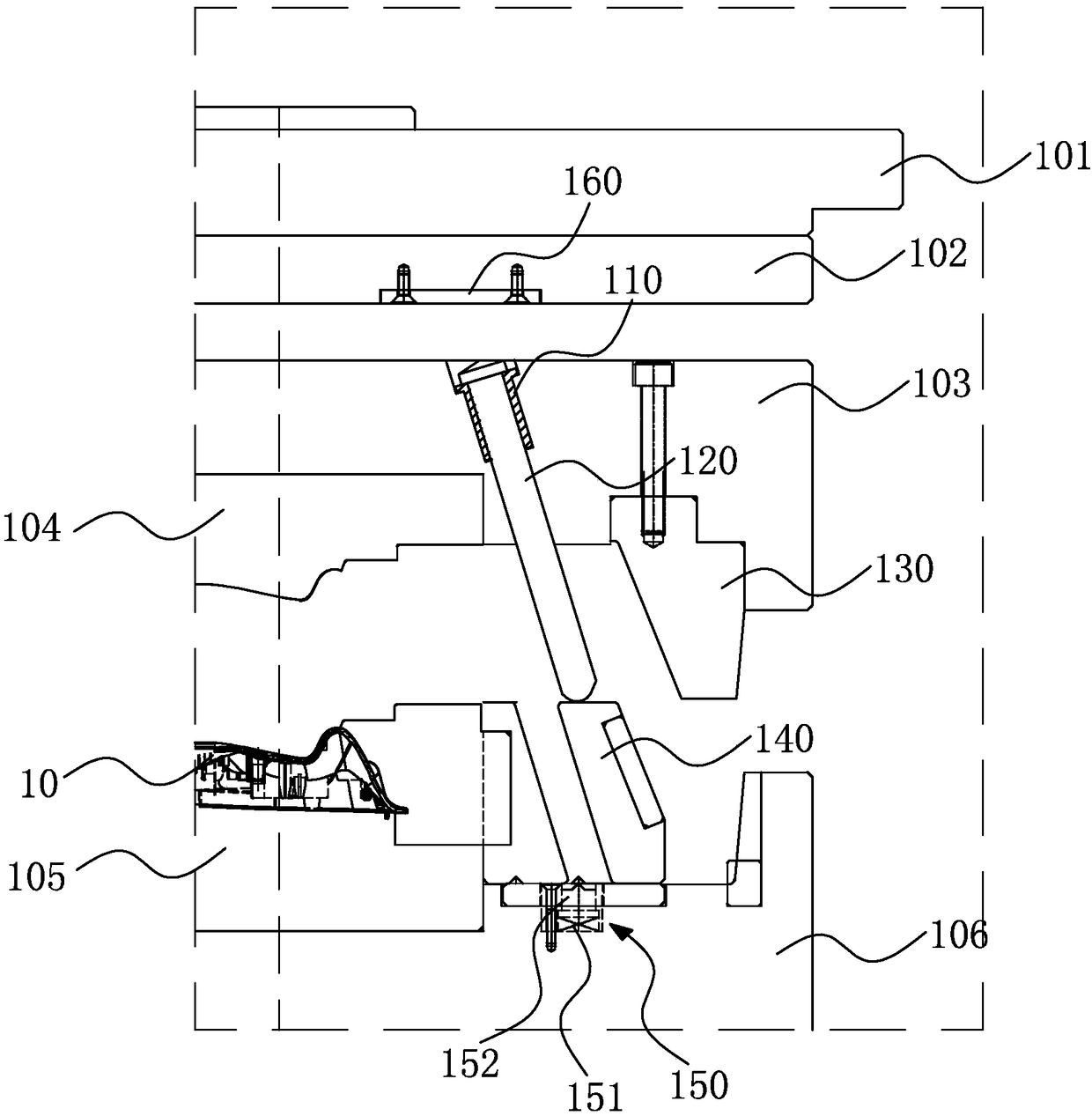

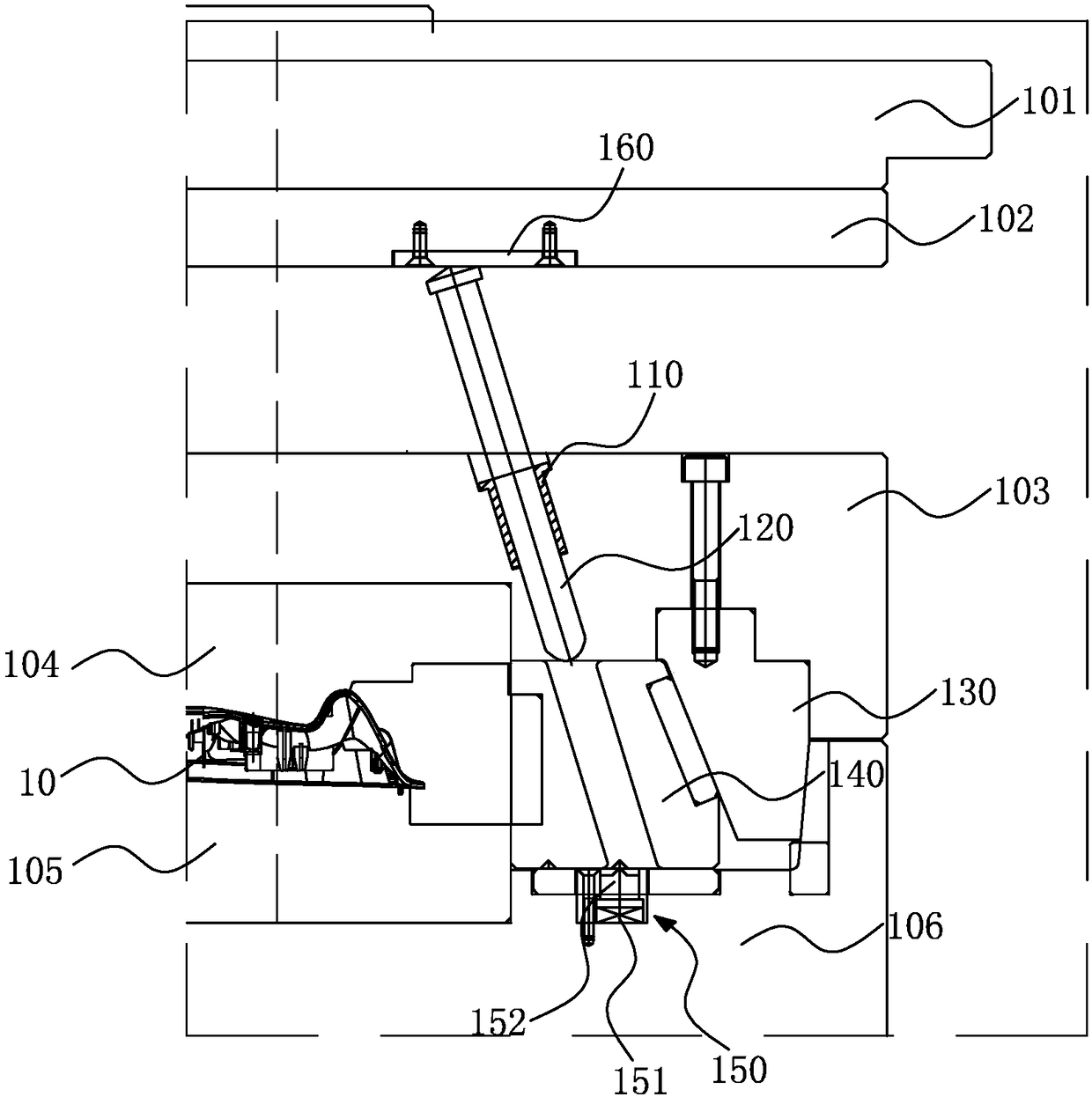

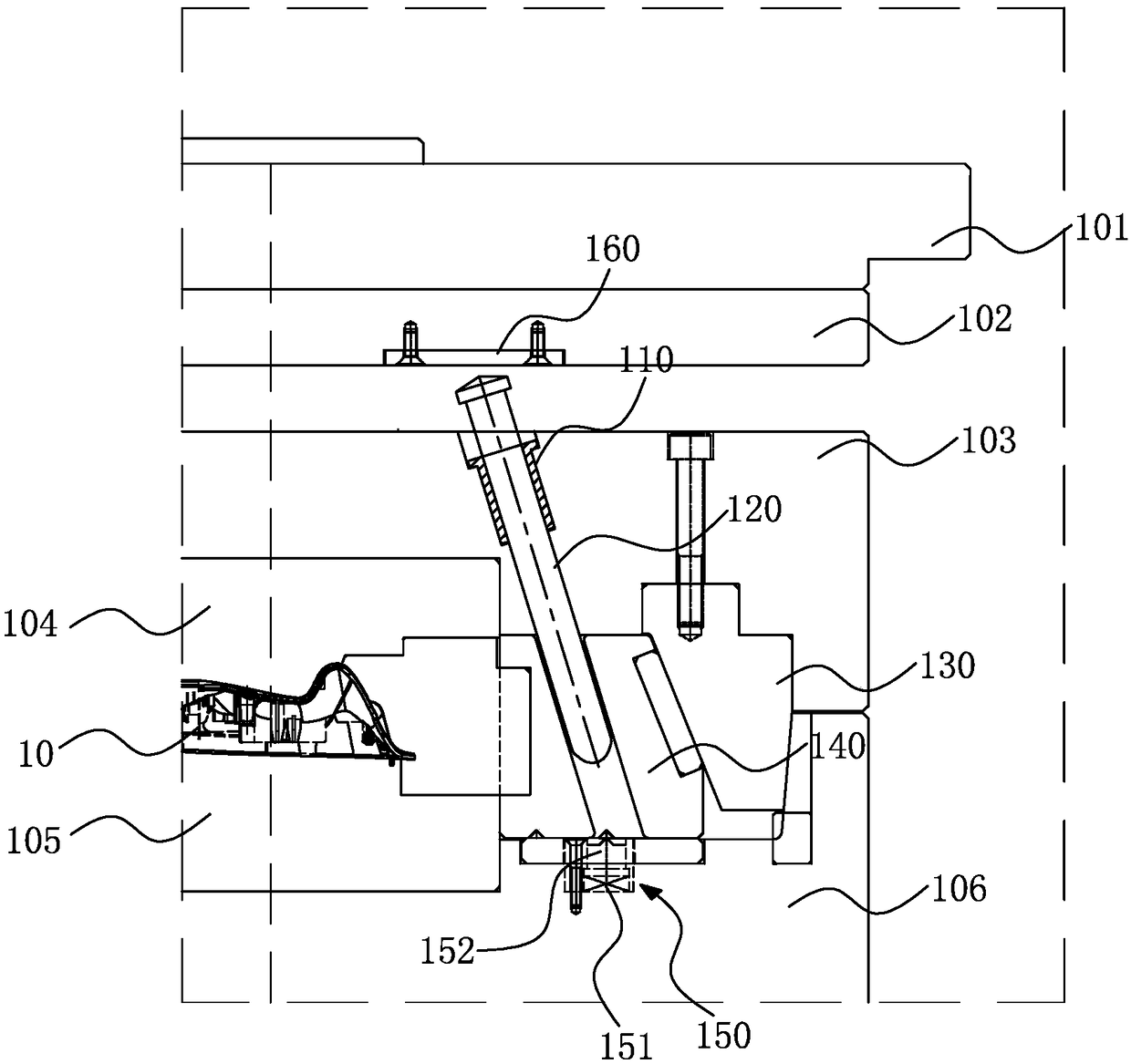

[0026] Please refer to figure 1 , figure 1 It is a schematic cross-sectional structure diagram of the ejection mechanism of the slider of the two-color mold of the present invention. The two-color mold slider withdrawal mechanism 100 of the present invention is applied to a mold for forming a product 10, and the mold includes an upper fixing plate 101, a stripping plate 102, a female template 103, a female mold core 104, a male mold core 105 and a male mold core 105. Template 106, the two-color mold slider ejection mechanism 100 includes:

[0027] An inclined guide sleeve 110, which is arranged on the upper end of the mother template 103, and the inside of the inclined guide sleeve 110 is a hollow structure;

[0028] an oblique guide post 120, which is slidably sleeved in the oblique guide sleeve 110;

[0029] A bundle block 130,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap