Ceramic deflocculating agent and preparation method thereof

A decoagulant and ceramic technology, applied in the field of ceramic decoagulant and its preparation, can solve the problems of side effects, easy coagulation, narrow degumming range, etc., achieve good fluidity and viscosity, simple production process and easy conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

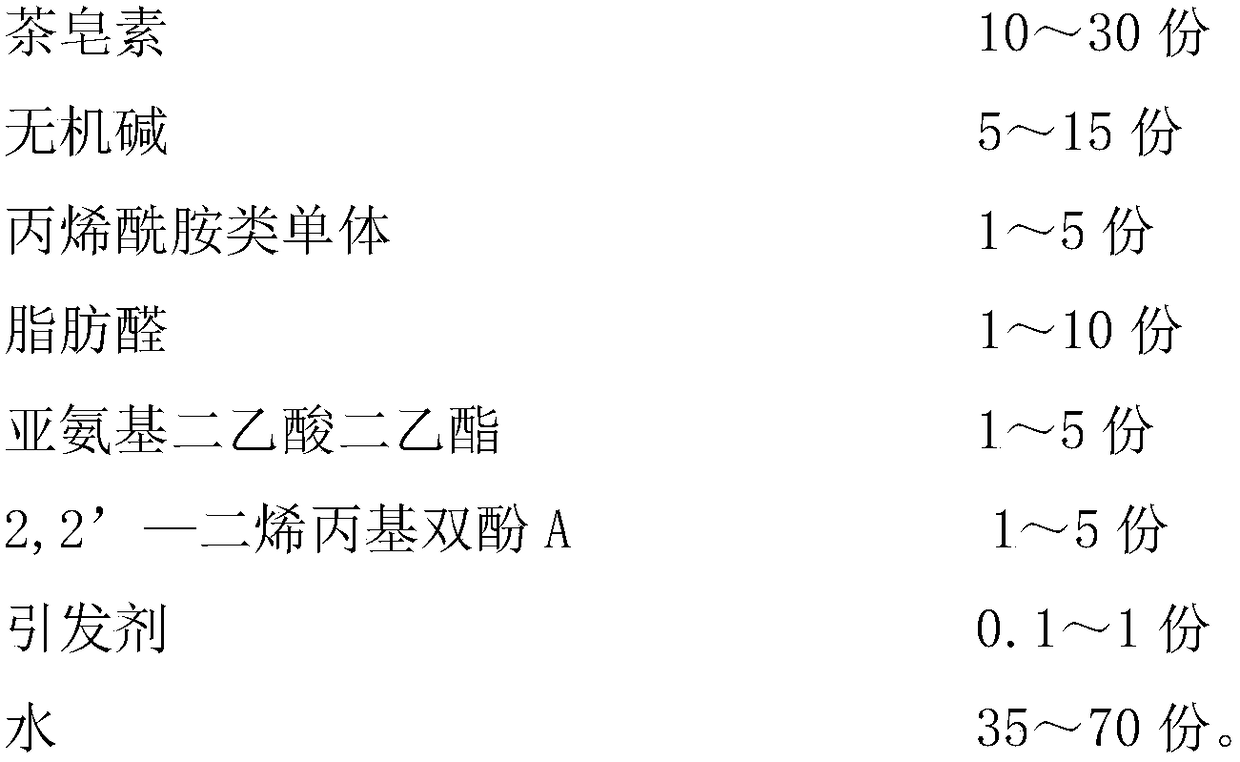

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a ceramic decoagulant is realized through the following steps:

[0027] (1) Add tea saponin, inorganic base, acrylamide monomer, and water into the reaction tank, start stirring and raise the temperature, add fatty aldehyde after the temperature rises to 80°C-150°C, and react for 1-3 hours;

[0028] (2) Then add diethyl iminodiacetate and 2,2'-diallyl bisphenol A, after stirring for 0.5 to 2 hours, add an initiator, and continue to react for 1 to 3 hours;

[0029] (3) Cooling and discharging to obtain the ceramic decoagulant.

Embodiment 1

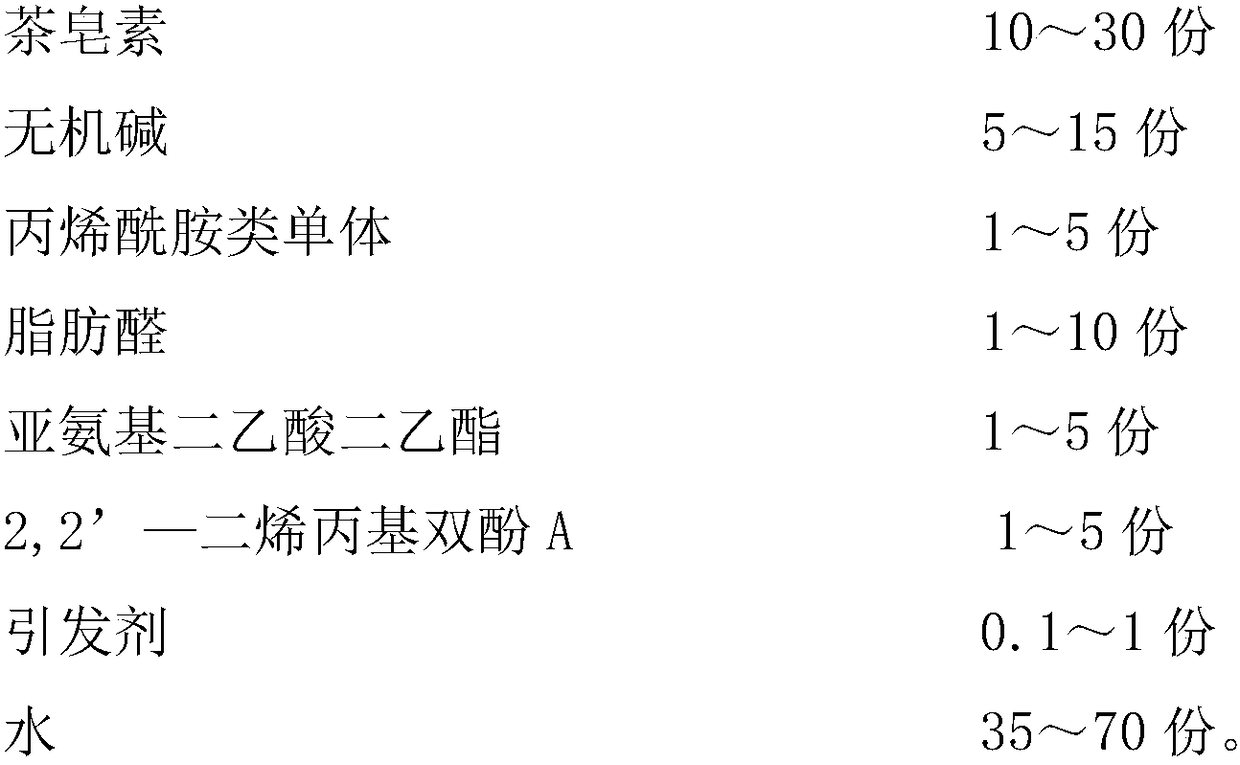

[0032] A kind of ceramic decoagulant of the present invention is made of the raw material components of following mass fraction ratio:

[0033]

[0034] A kind of preparation method of ceramic decoagulant of the present invention is realized by following steps:

[0035] (1) Add 15 parts of tea saponin, 14.5 parts of sodium hydroxide, 1.5 parts of acrylamide, and 63.8 parts of water into the reaction tank, start stirring and raise the temperature. After the temperature rises to 90°C, add 2 parts of formaldehyde and react for 1.5 hours ;

[0036] (2) Then add 2 parts of diethyl iminodiacetate and 1 part of 2,2'-diallyl bisphenol A, after stirring for 1 hour, add 0.2 parts of benzoyl peroxide, and continue the reaction for 1.5 hours;

[0037] (3) Cooling and discharging to obtain the ceramic decoagulant.

Embodiment 2

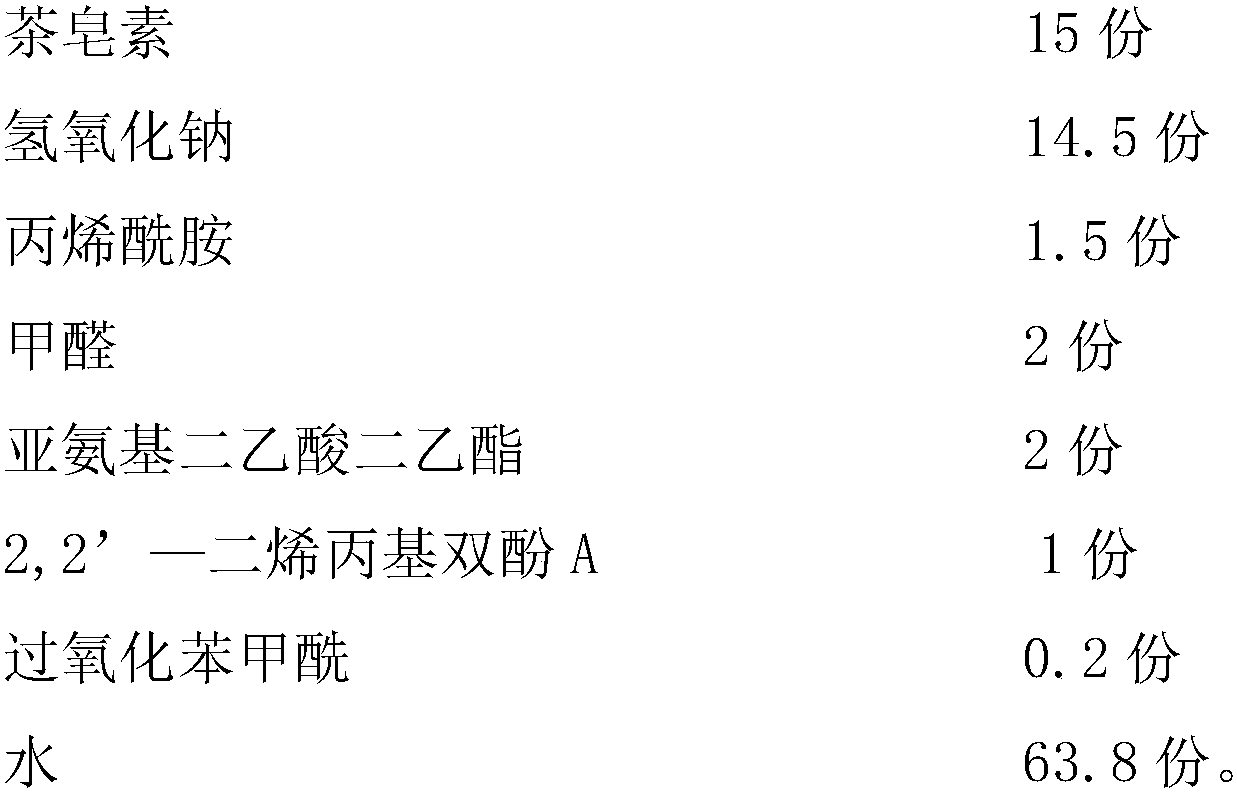

[0039] A kind of ceramic decoagulant of the present invention is made of the raw material components of following mass fraction ratio:

[0040]

[0041] A kind of preparation method of ceramic decoagulant of the present invention is realized by following steps:

[0042] (1) Add 12 parts of tea saponin, 12 parts of sodium hydroxide, 2 parts of methylolacrylamide, and 66.2 parts of water into the reaction tank, start stirring and raise the temperature, and add 3.5 parts of acetaldehyde after the temperature rises to 105°C , react for 2 hours;

[0043] (2) Then add 2.5 parts of diethyl iminodiacetate, 1.5 parts of 2,2'-diallyl bisphenol A, after stirring for 1 hour, add 0.3 parts of dicumyl peroxide, and continue to react for 1.8 hours;

[0044] (3) Cooling and discharging to obtain the ceramic decoagulant.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap