Vacuum permanent magnet energy conversion system

A technology of permanent magnetic energy and vacuum, applied in the direction of permanent magnetic clutches/brakes, electrical components, electromechanical devices, etc., can solve problems such as insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

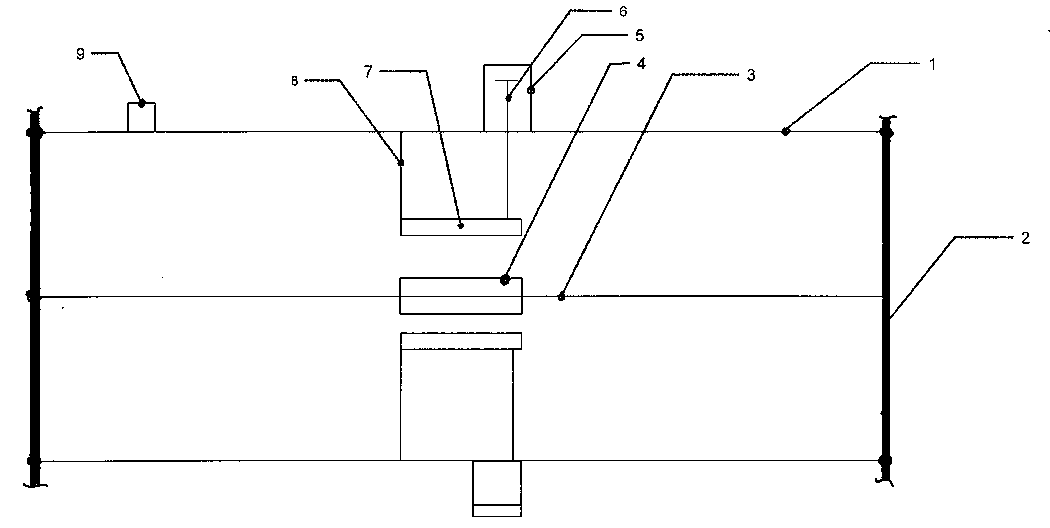

[0013] Refer to the attached drawings: The designed vacuum permanent magnet energy transformation system includes: a walking permanent magnet block 4 connected by a driving link 3, a reciprocating permanent magnet block 7 and a fixed outer frame 1, of which: fixed outer frame 1 and drive shaft 2 The drive shaft 2 is connected with the drive chain 3, the drive chain is connected with the walking permanent magnet block 4. The walking permanent magnet block 4. only travels in a straight line, the high pressure cylinder 5 is connected to the fixed frame 1, the piston connecting rod 6 is connected to the reciprocating permanent magnet block 4. The magnetic block 7 is connected, the reciprocating permanent magnet block 7 is connected with the movable permanent magnet block fixing rod 8, the movable permanent magnet block fixing rod is connected with the fixed outer frame 1, and the vacuum valve 9 is connected with the fixed outer frame 1.

[0014] When working, first fix two reciprocating

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap