Combined lock nut

An anti-loosening nut, combined technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of parts or equipment damage, safety accidents, limited use conditions, inability to be widely used, etc., to achieve increased friction, good sealing effect, Good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

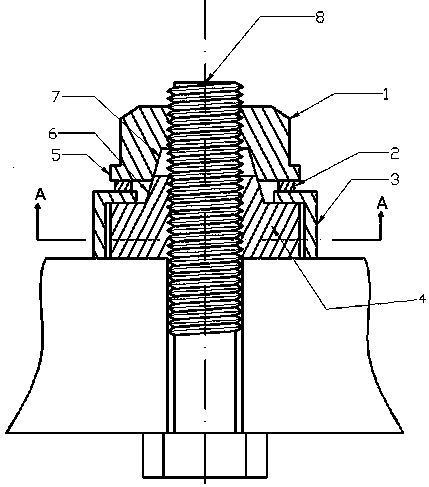

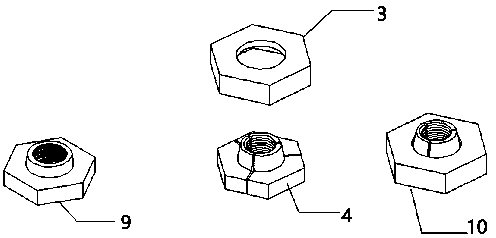

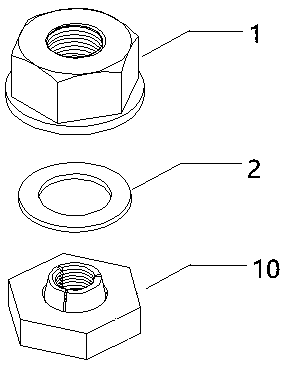

[0023] Such as figure 1 and image 3 As shown, a combined locknut includes a lock nut 1 , a rubber washer 2 and a combined nut 10 . There is a concave round table 7 inside one end of the lock nut 1, and a flange surface 5 outside; the three split nuts 4 of the combined nut 10 are placed in the support sleeve 3 according to the corresponding sequence on the convex nut 9 before being divided, The rotation directions of the threads of each split nut 4 are the same, and there are equal circumferential gaps 11 between every two split nuts 4 , and the split nuts 4 can only Produce the radial displacement along bolt 8; Because the taper of lock nut concave round table 7 is identical with the taper of the convex round table of convex nut 9, so the inner surface of lock nut concave round table 7 and the outer surface of split nut convex table 6 can coincide.

[0024] When assembling, install the combination nut 10 first, then place the rubber gasket 2, and finally install the lock nut

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap