Water chilling unit provided with super-cooler and lubricating oil cooler

A chiller and lubricating oil technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as excessive lubricating oil temperature, abnormal operation of expansion valves, and large space occupied by condensers, so as to improve temperature accuracy, Good supercooling effect and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

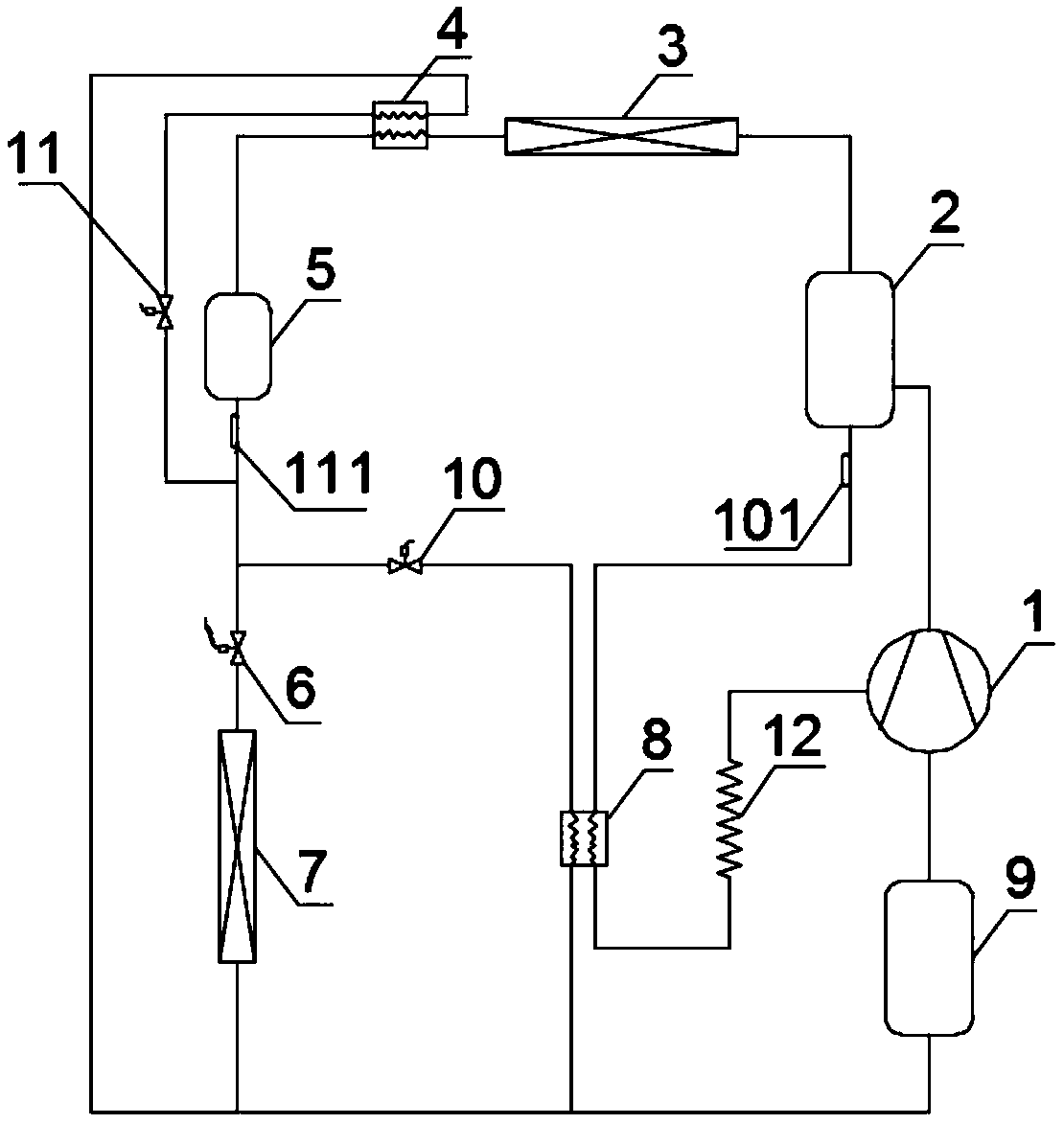

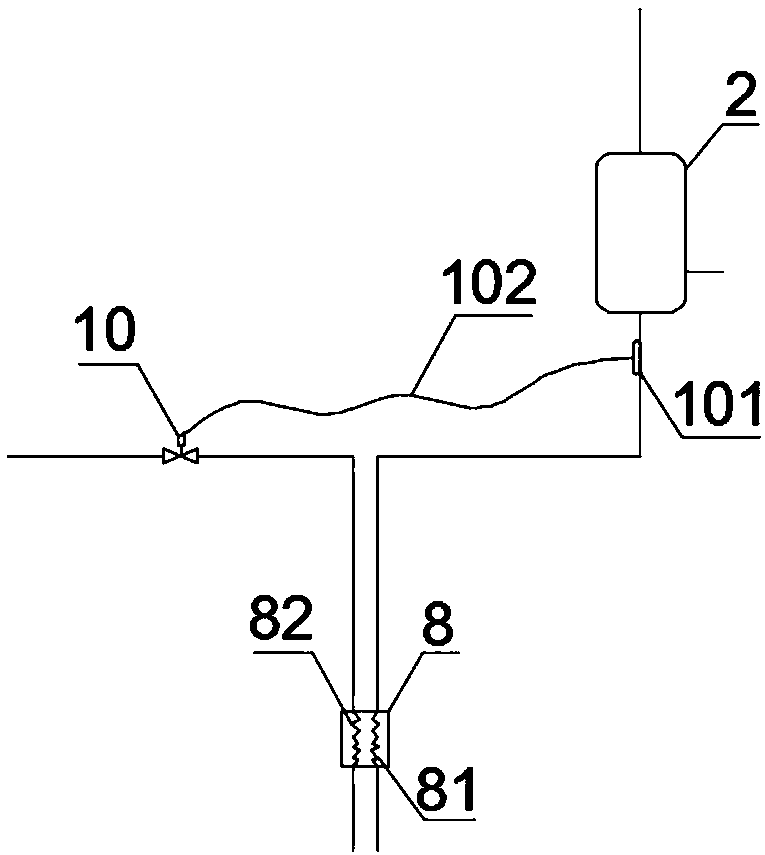

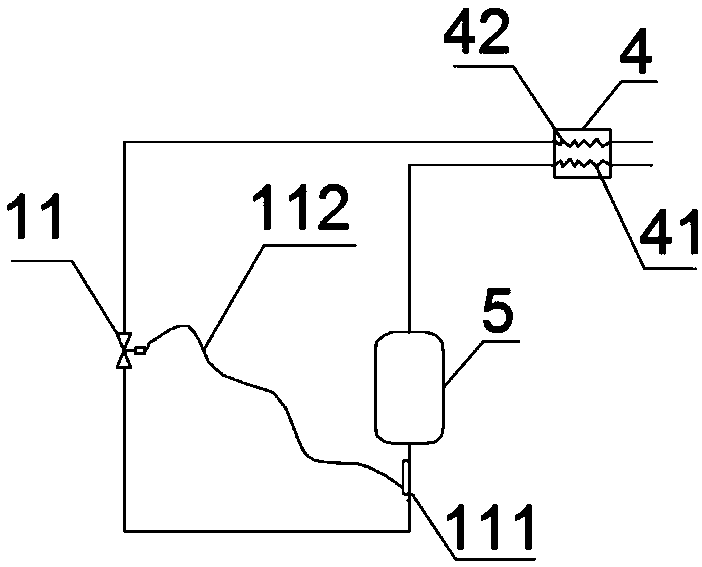

[0024] see figure 1 , figure 2 , image 3 with Figure 4 , the water chiller provided with subcooler and lubricating oil cooler in this embodiment includes compressor module 1, condenser 3 and evaporator 7; the chiller also includes: oil separator 2, subcooler 4, liquid storage device 5, thermal expansion valve 6, lubricating oil cooler 8, gas-liquid separator 9, and a first control valve 10 and a second control valve 11 with auxiliary control functions.

[0025] Such as figure 1 As shown, an oil separator 2 is arranged at the outlet end of the compressor module 1, and the refrigerant gas outlet end of the oil separator 2 is sequentially connected to the condenser 3, the subcooler cooling passage 41 of the subcooler 4, and the liquid accumulator 5 , thermal expansion valve 6, evaporator 7, gas-liquid separator 9, and return to the suction end of the compressor module 1, constituting the main passage of the chiller.

[0026] figure 1 Also shown in the figure: between the ou

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap