Moving mechanism of numerical control machine tool and lubricating method thereof

A technology of moving mechanism and numerically controlled machine tools, applied in the field of machine tools, which can solve problems such as the inability to automatically switch between lubricating fluids, uneven addition of lubricating fluids, and inability to ensure stable work, etc., and achieve the effects of wide application range, stable work, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

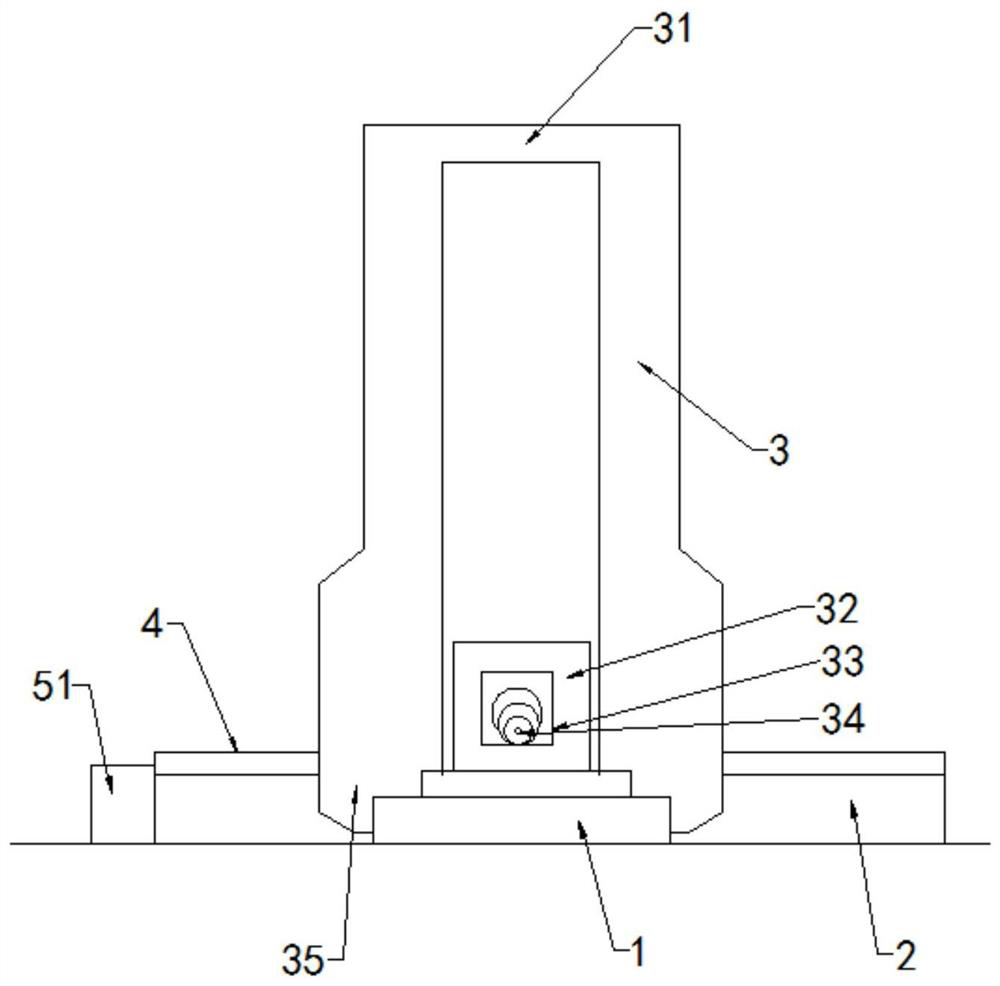

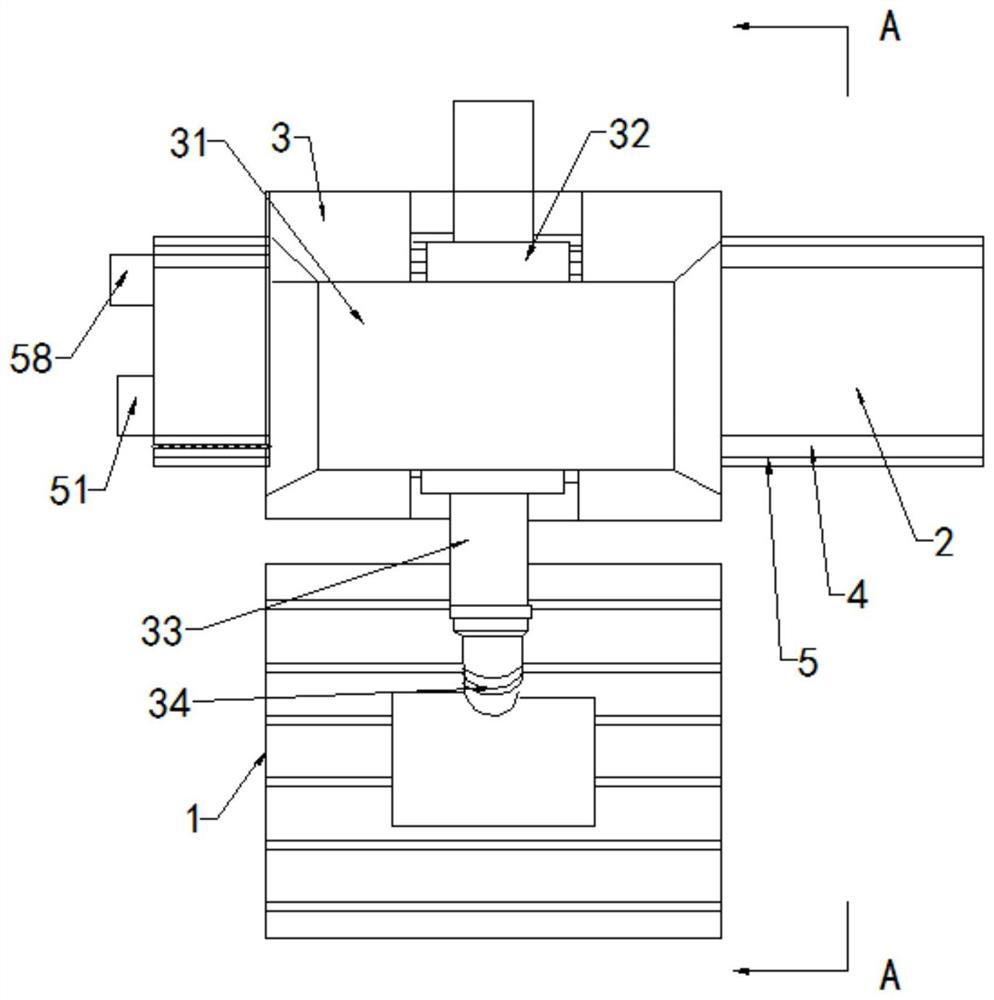

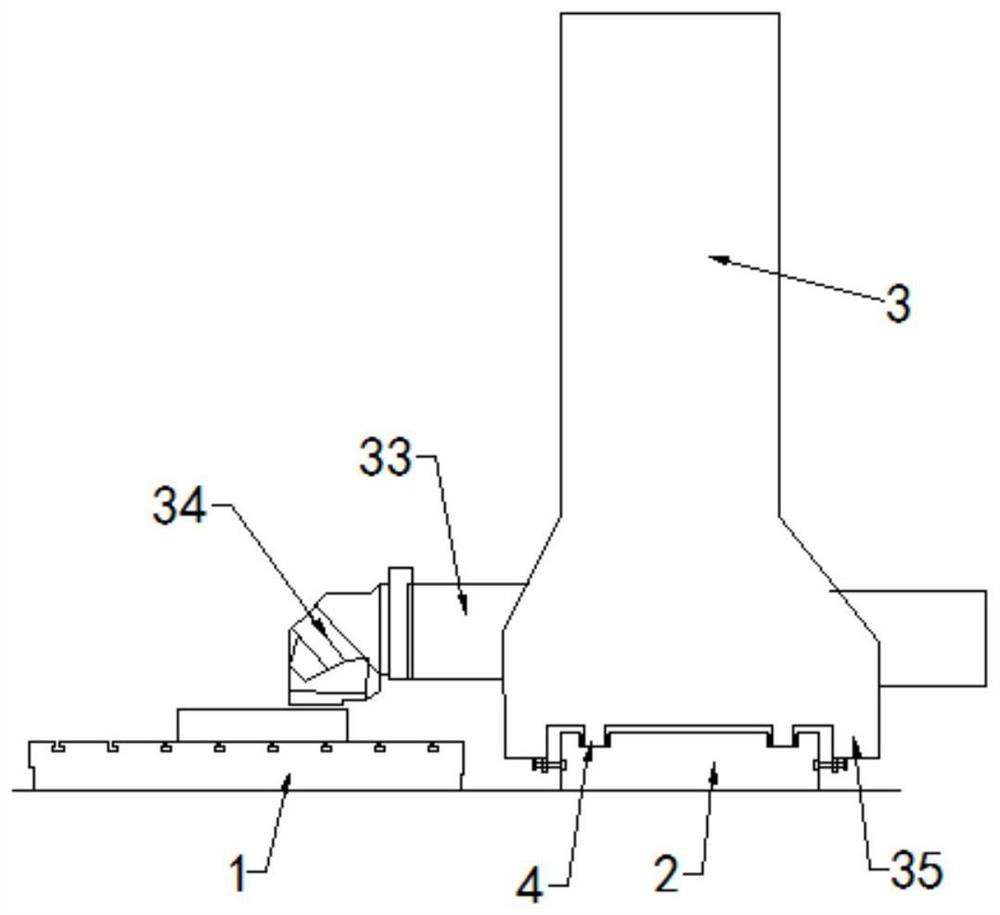

[0039] Such as Figure 1 to Figure 5 As shown, the present invention discloses a moving mechanism of a numerical control machine tool. In a specific embodiment of the present invention, it includes a workbench 1 and a base 2 fixed on the ground, and the base 2 is provided with a column that can slide along it. 3. The column 3 is slidably arranged on the base 2 through the sliding mechanism 4; the column 3 is two, and the upper ends of the two columns 3 are integrally formed by welding the beam 31, and the inner walls of the two columns 3 are provided with movable The slide block 32 that slides vertically on the inner side wall of the column 3 includes a drive mechanism that controls the slide block to move up and down and a drive mechanism that controls the column to move on the base in this embodiment (the drive mechanism is a transmission technology so no more details here. description), one end of the slider 32 is fixed with a slider 33, and the slider 33 can move axially rela

Embodiment 2

[0047] Such as Figure 8 and Figure 9 As shown, the difference between this embodiment and the above-mentioned embodiments is that in this embodiment, several oil storage units 6 are evenly opened on the bottom of the sliding groove 42, and each oil storage unit 6 includes a first oil storage tank 61 and a first oil storage tank 61. The second oil storage tank 62, the first oil storage tank 61 and the second oil storage tank 62 are circular tanks, the first oil storage tank 61 and the second oil storage tank 62 are concentrically arranged, and the diameter of the first oil storage tank 61 It is larger than the second oil storage groove 62; the bottom of the sliding groove 42 is also provided with a first flow groove 63 and a second flow groove 64, and the first flow groove 63 is located at the first oil storage groove 61 and the second oil storage groove 62 Between, the first flow groove is evenly arranged around the circumference of the second oil storage groove, the first flo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap