Detection apparatus for sliding detection of hood fitting clearances and application method thereof

A technology for testing equipment and installation clearance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of large production error of front hatch cover and easy damage of rotating parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

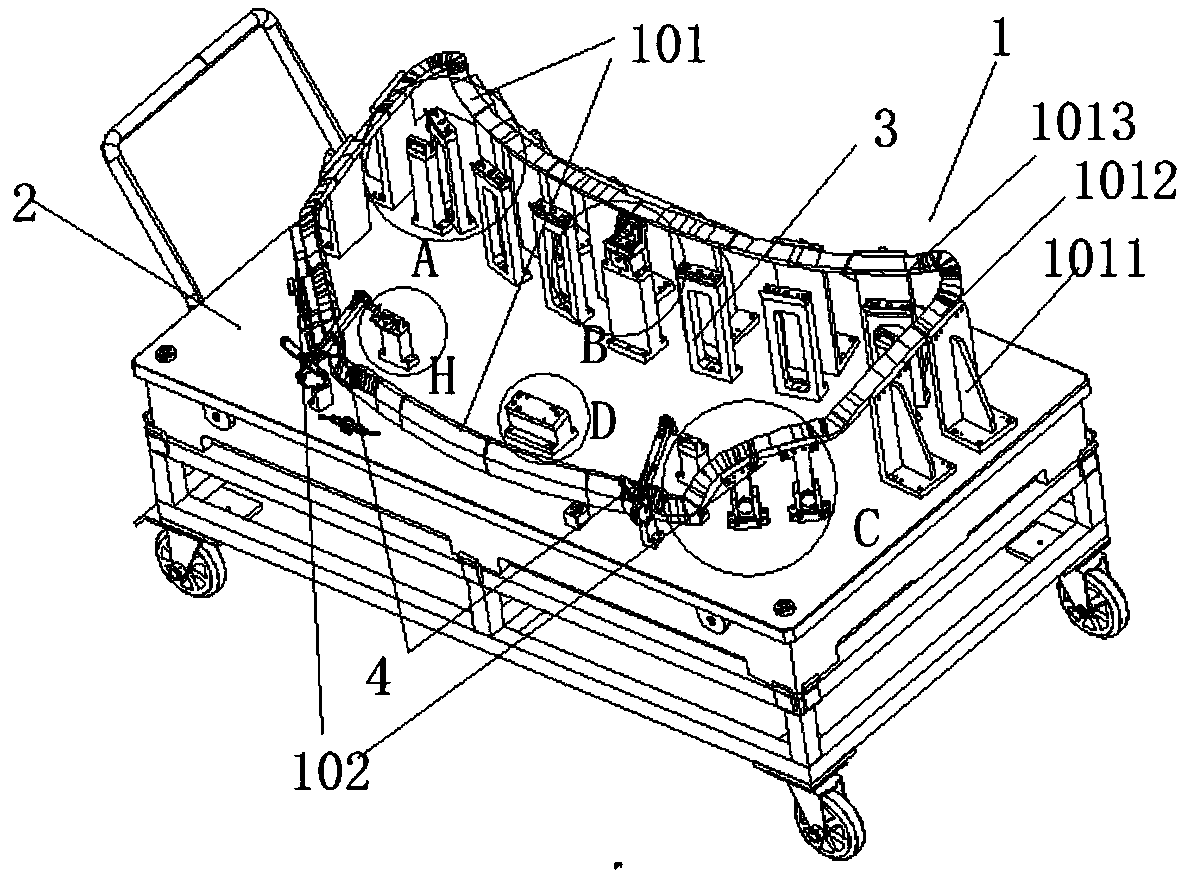

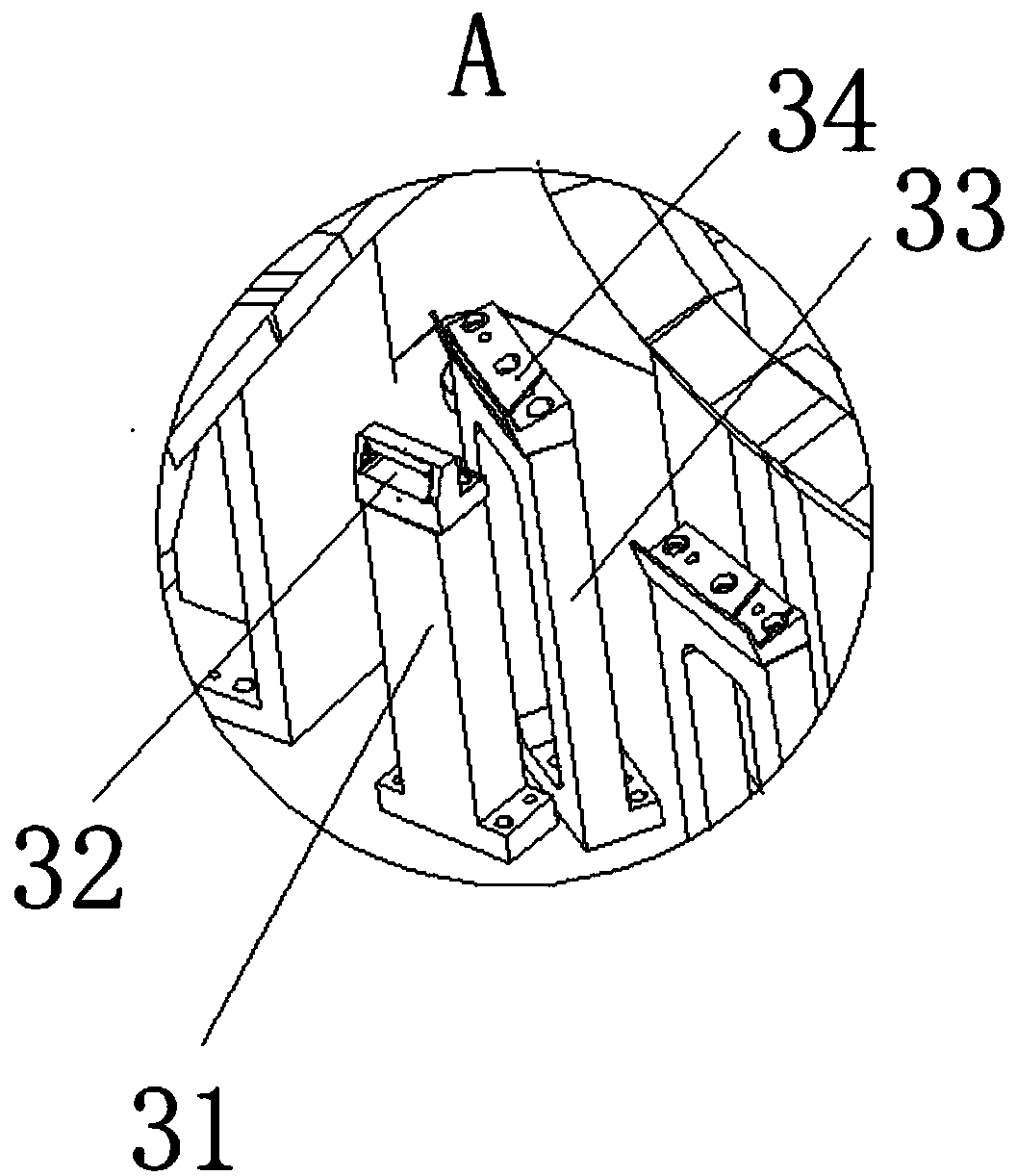

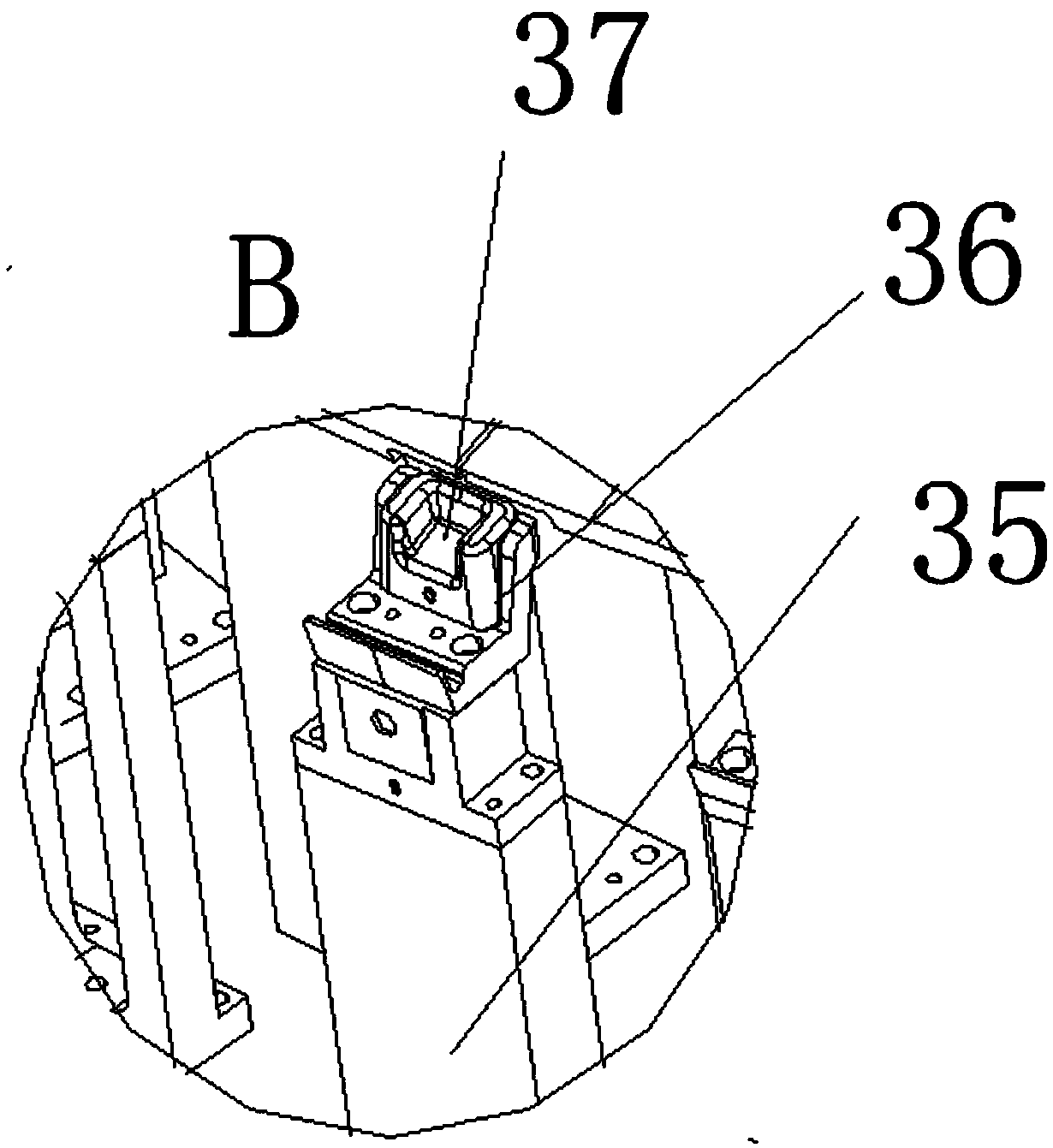

[0040] A detection device for detecting the installation gap of a pull-out front hatch cover. The detection device includes a detection platform 2, on which a support assembly 3 for placing the front hatch cover is provided; The standard detection component 1 of cover installation accuracy; Standard detection component 1 comprises fixed detection component 101 and movable detection component 102; Detection equipment also comprises the distance between fixed standard surface 1013 or movable standard surface 1024 and the front hatch cover to be tested The detection part 5, the present invention provides a kind of detection equipment for detecting the joint gap between the front hatch cover and the adjacent parts when the front hatch cover is installed in the whole vehicle. The placement of the c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap