Middle distillate desulphurization device

A technology for middle distillate oil and desulfurization device, applied in the field of desulfurization, can solve the problems of high maintenance cost, high cost and high energy consumption, and achieve the effects of less loss of octane number, low processing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

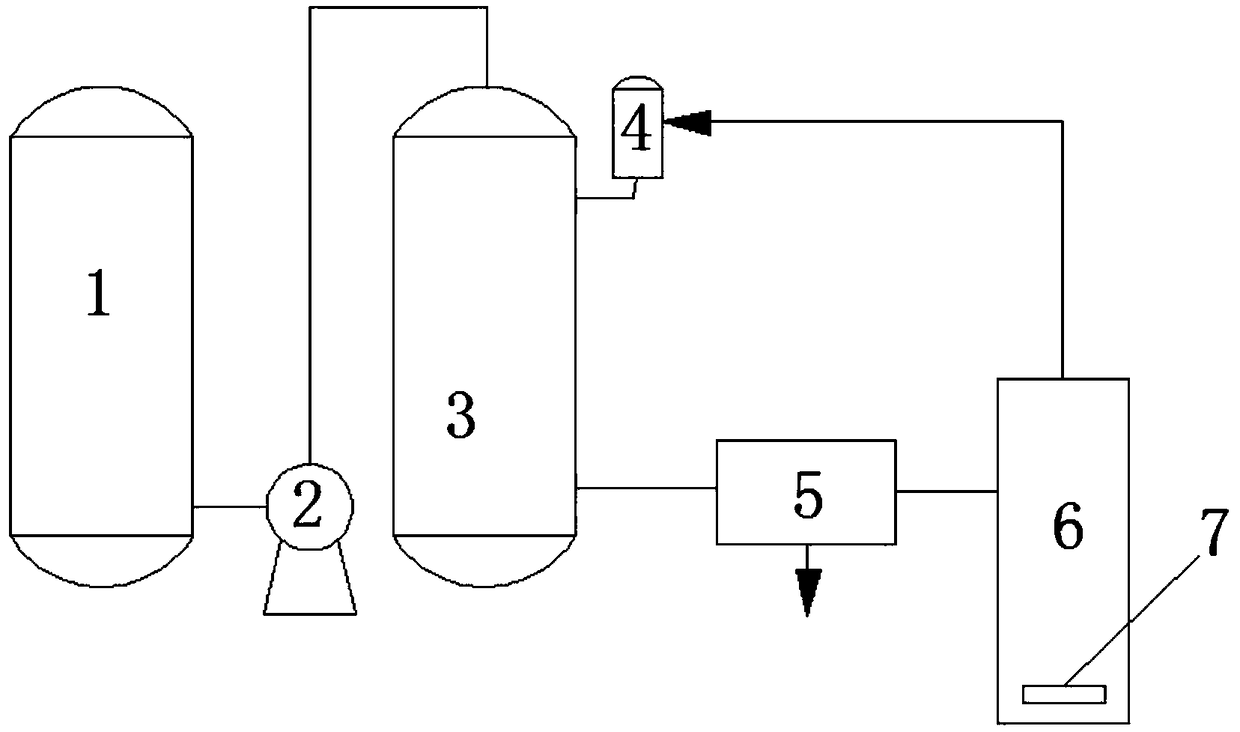

[0014] attached figure 1 It is a specific embodiment of the present invention. The invention is a middle distillate desulfurization device, comprising a crude oil tank, a desulfurization reaction tank and an adsorbent regeneration tank. The crude oil tank is communicated with the desulfurization reaction tank through a crude oil pump, and the desulfurization reaction tank is regenerated with the adsorbent through a solid-liquid separator. The tank is connected, and the desulfurization reaction tank is connected with an adsorbent storage tank.

[0015] Further, an ultrasonic generator is provided at the inner bottom of the adsorbent regeneration tank.

[0016] Further, the raw material composition of the adsorbent in the adsorbent storage tank is as follows: 20-50 parts of molecular sieve particles; 60-95 parts of ethanol solution; 9-16 parts of zinc oxide; 10-20 parts of manganese dioxide solution .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap