Ore pulverizer for mine exploiting

A pulverizer and ore technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as inability to use, cannot be applied to complex terrain, etc., achieve high practicability, ensure stable long-term work, The effect of ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

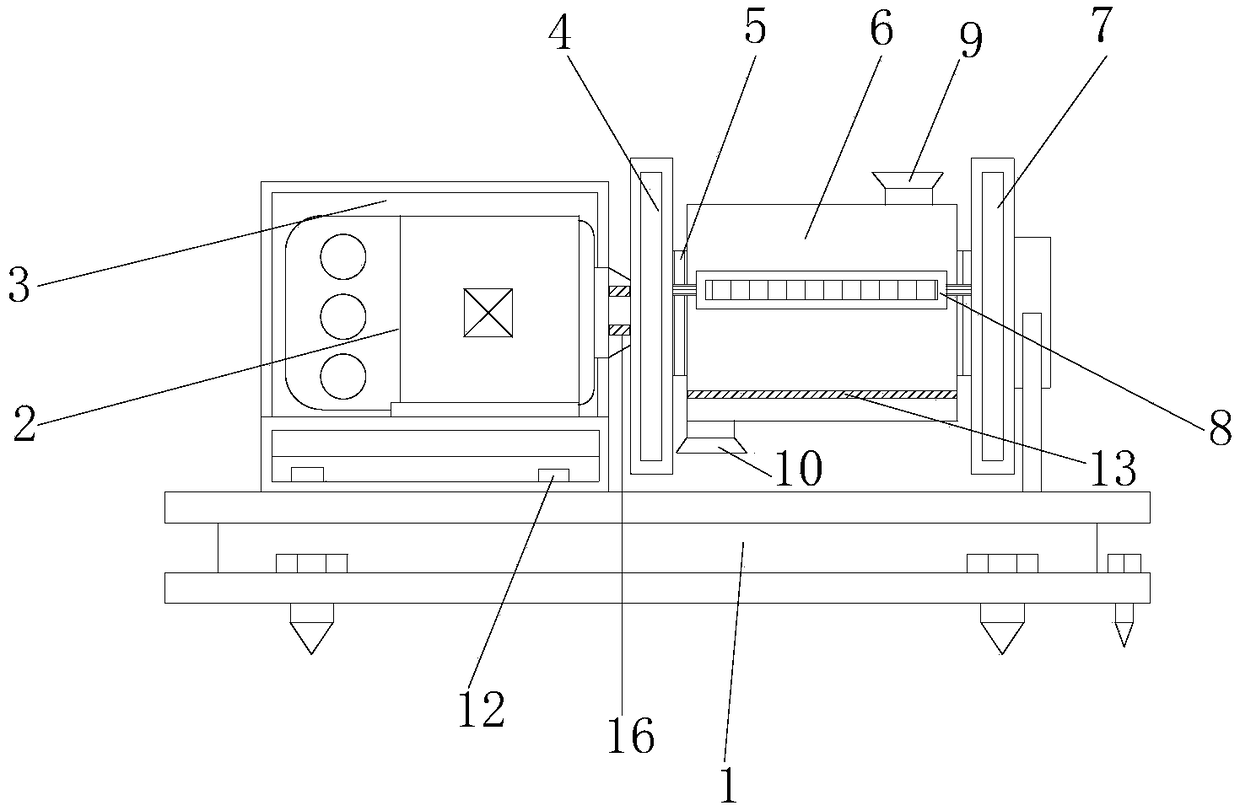

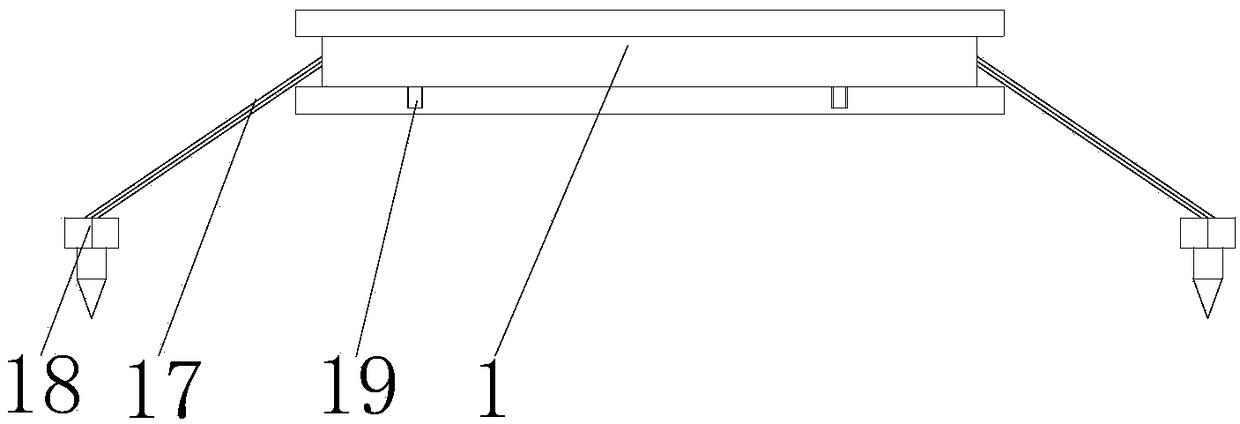

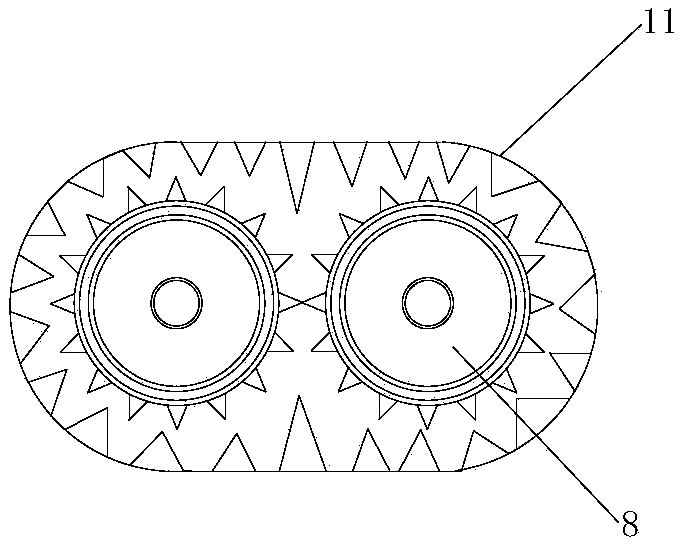

[0023] see Figure 1-5 , the present invention provides a technical solution: an ore crusher for mining, including a base 1, a servo motor 2, a protective cover 3, a left support plate 4, a protection mechanism 5, a crushing mechanism 6, a right support plate 7, and a crushing roller 8. Feed port 9, discharge port 10, crushing chamber 11, connecting nail 12, filter plate 13, baffle plate 15, bearing bush 16, connecting rope 17, reinforcing nail 18,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap