A rail rotary plug-and-pull type socket

A technology of plug-in and plug-in sockets, which is applied in the field of orbital rotary plug-in sockets, can solve the problems of messy use of wiring harnesses, inability to expand sockets, and lack of mobility, etc., and achieve simple appearance, good use effects, and improved use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

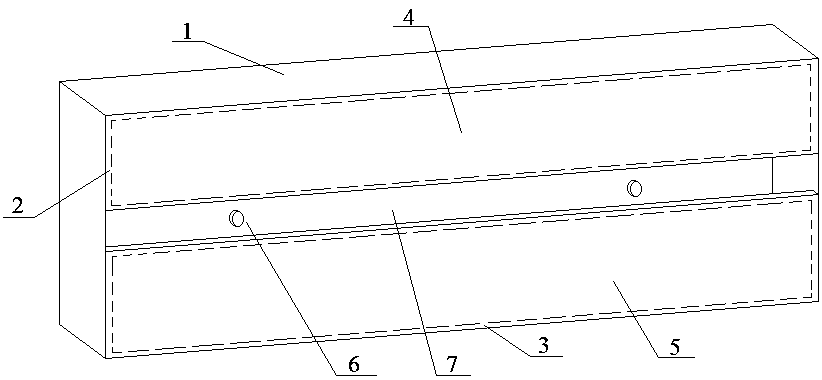

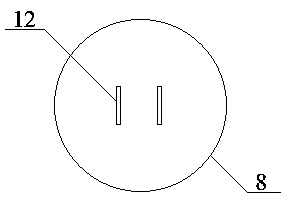

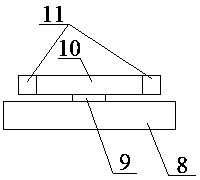

[0021] like figure 1 As shown, the present invention designs an orbital rotary plug-in socket, which includes a base and at least one socket body; wherein, the base includes a base box 1, an upper rectangular cover 2, a lower rectangular cover 3, and an upper conductive plate 4. and the lower conductive plate 5; the base box 1 is in the shape of a cuboid, and one of the sides where the long side and the broad side of the base box 1 are coplanar is set to be open; the thickness of the upper rectangular cover plate 2 is equal to the thickness of the lower rectangular cover plate 3 , the length of the long side of the upper rectangular cover plate 2 and the length of the long side of the lower rectangular cover plate 3 are equal to the length of the upper long side of the base box 1, and the width of the upper rectangular cover plate 2 and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap