Multilayer special-shaped cosmetic filling system

A filling system, cosmetic technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of single material body, single color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

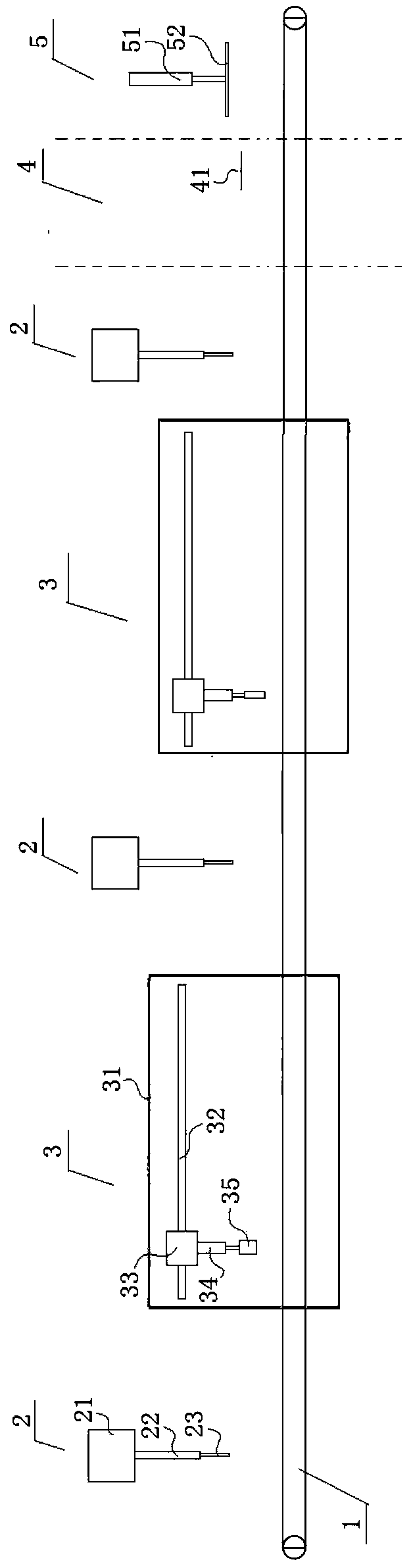

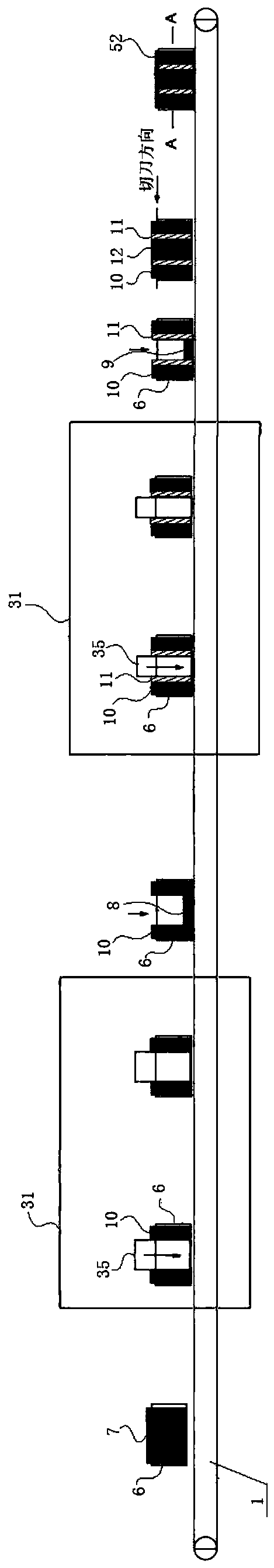

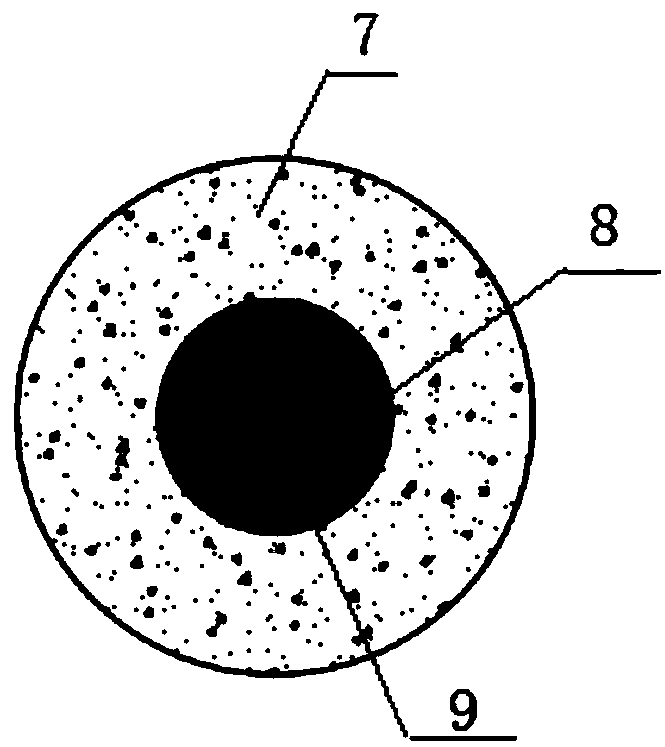

[0028] A multi-layer special-shaped cosmetic filling system, such as Figure 1~2 As shown, it is used to form multi-layer special-shaped cosmetics in wide-mouth packaging material 6. Multi-layer special-shaped cosmetics are composed of a plurality of special-shaped cosmetic layers arranged sequentially from outside to inside. It is characterized in that the system includes a transmission mechanism 1, along A plurality of filling stations 2 arranged sequentially in the conveying direction of the conveying mechanism 1 and freezing plug mold stations 3 respectively arranged between two adjacent filling stations 2;

[0029] The transmission mechanism 1 is used to carry and transmit the wide-mouth packaging material 6;

[0030] A plurality of filling stations 2 are used to pour the materials of various cosmetic layers into the wide-mouth packaging material 6 sequentially from the outer layer to the inner layer;

[0031] Freezing plug mold station 3 is used to insert a special-shaped

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap