Process of artificial stone moulding and manufacture for decoration of building

An artificial stone and building technology, applied in building structure, construction, manufacturing tools, etc., can solve problems such as rain sound and noise, and achieve the effect of simple construction, uniform overall thickness and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of artificial stone molding for building decoration and its manufacturing method according to the present invention will be described in detail with reference to the accompanying drawings.

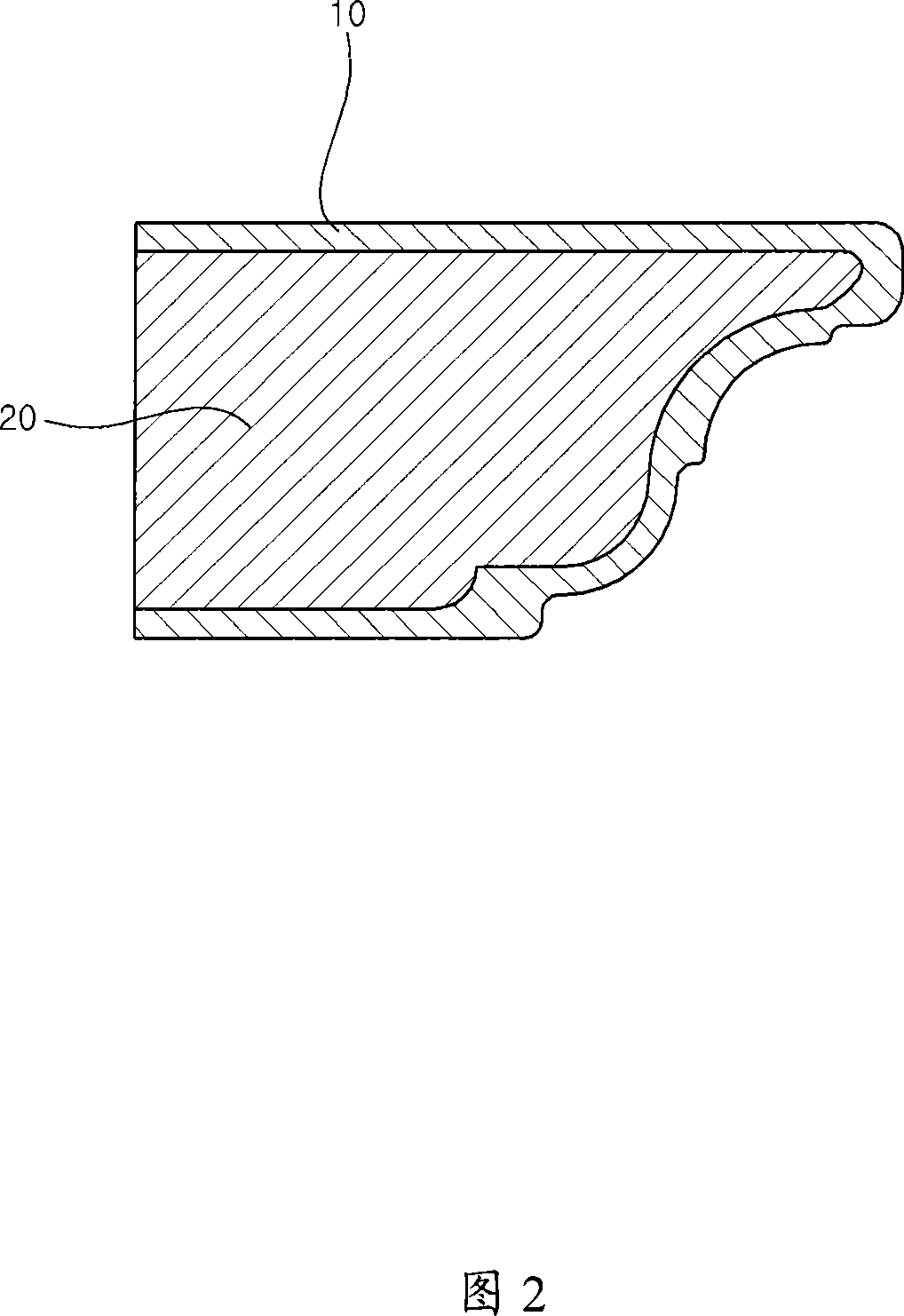

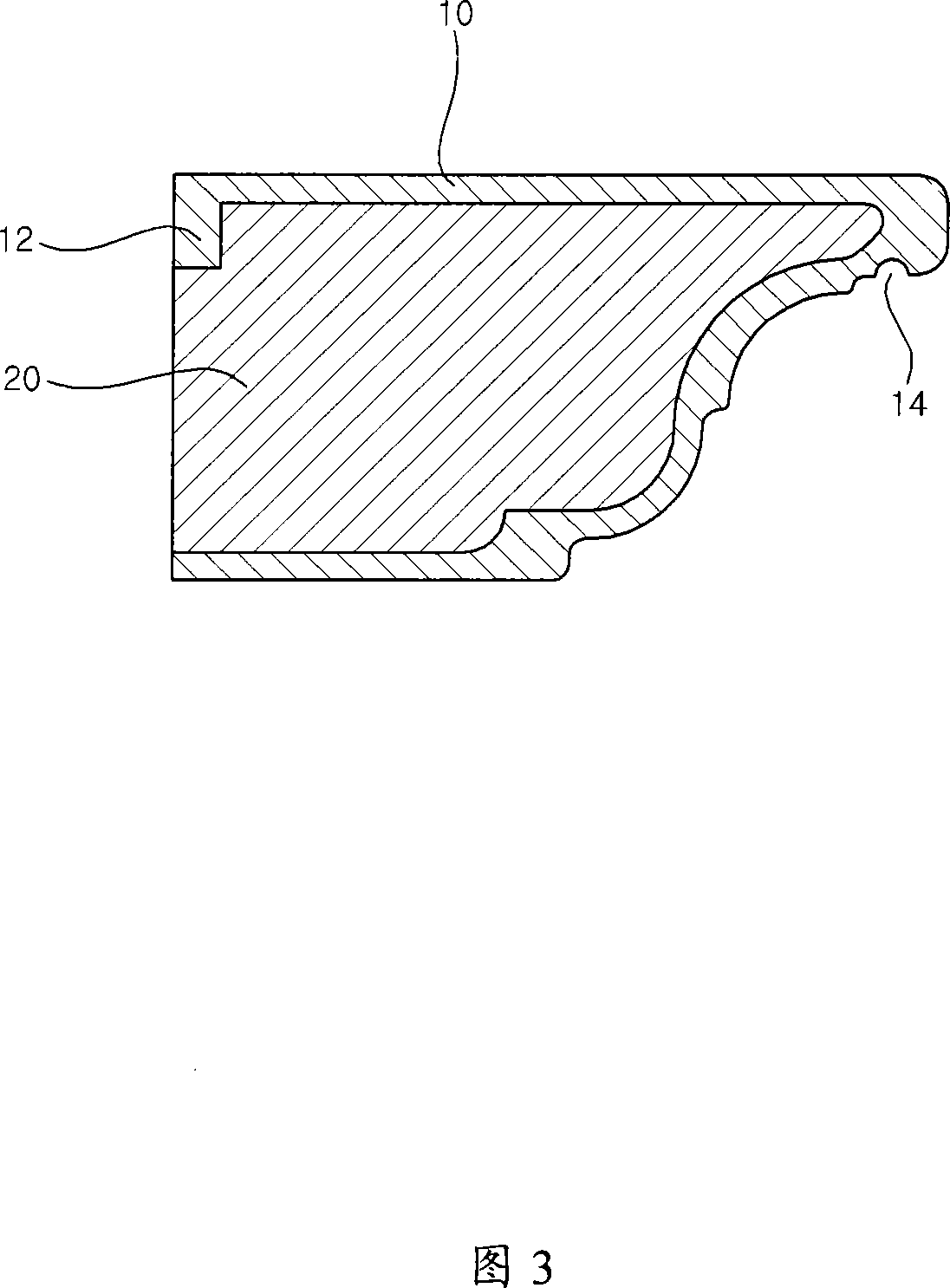

[0049] First of all, the first embodiment of artificial stone molding for building decoration of the present invention is shown in Fig. 1 and Fig. 2, comprising: facing material 10, which is barrel-shaped with one side open and hollow inside, and is formed of artificial stone; The quality filling material 20 is filled in the interior of the decoration material 10 and integrated with it, and is formed into a foam shape.

[0050] The facing material 10 is molded using artificial stone slurry, and the artificial stone slurry is evenly stirred by adding water to the raw material prepared by mixing 40% to 90% aggregate and 10% to 60% cement And made.

[0051] Wherein, the raw materials of the artificial stone slurry can also be mixed with 40% to 80% of ag

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap