Construction method of tunnel center inspection well lid adaptive to heavy traffic rolling

A tunnel center and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as subsidence, hidden dangers, edge peeling, etc., to achieve large bearing capacity, improve bearing capacity, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

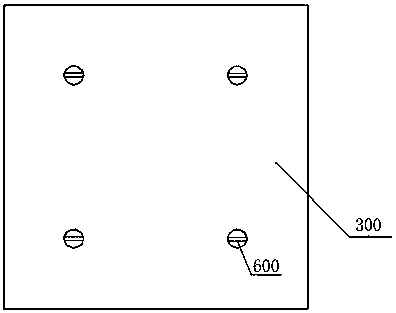

[0046] A certain expressway tunnel is separated, with a design speed of 80 km / h. The left and right tunnels are both 11,200 meters long, with a clear height of 5 meters and a clear width of 10.25 meters. The design drawing of the inspection well cover in the center of the tunnel is as follows: Figure 8 shown, from Figure 8 It can be seen that the original design of the cover plate 300 is thin (20 cm thick), the concrete grade is low (C25), and the bottom bearing part of the cover plate 300 has not been specially treated; at the same time, the gap between the cover plate 300 and the concrete pavement panel is made of ordinary Mortar filling, no special treatment. according to Figure 7 According to the design and construction shown, 3 to 5 months after the tunnel is opened to traffic, under the repeated impact of heavy vehicles, the cover plate 300 will gradually appear peeling, cracking and sinking at the corners, seriously affecting the normal traffic of the road and Ther

Embodiment 2

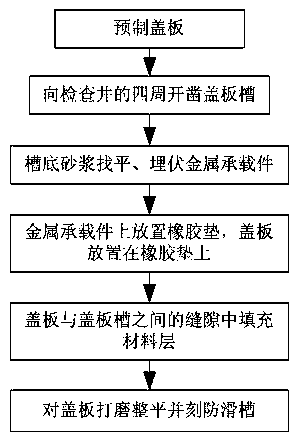

[0050] Such as figure 1As shown, the tunnel center manhole cover construction method suitable for heavy traffic rolling includes the following steps:

[0051] Step 1, prefabricated cover plate 300;

[0052] Step 2. Centering on the midpoint of the inspection well, drill the cover groove 2 around the inspection well;

[0053] Step 3: level the bottom of the cover plate groove 2 with mortar, and ambush the metal carrier before the mortar is solidified; in step 3, the thickness of the mortar is slightly larger than that of the metal carrier.

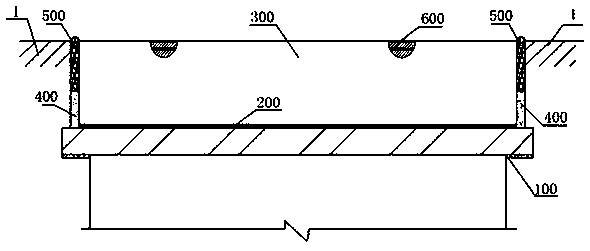

[0054] Step 4, place the rubber pad 200 on the metal carrier, and then place the cover plate 300 prefabricated in step 1 in the cover plate groove 2 in step 2, so that the surface of the rubber pad 200 is in contact with the bottom surface of the cover plate 300;

[0055] Step five, filling the material layer in the gap between the cover plate 300 and the cover plate groove 2 (ie, the pavement panel);

[0056] Step 6: Grinding and leveling

Embodiment 3

[0065] The traditional manhole cover for inspection wells in the center of the highway tunnel has a low label, thin thickness and a suspended base, and its bearing capacity is obviously insufficient. In addition, the gap between the traditional manhole cover and the concrete road surface is filled with mortar. Under the repeated action of vehicle dynamic load, It is constantly loosened and hollowed out, and then the overall sinking or damage occurs, endangering driving safety.

[0066] The design concept of this embodiment is: one, increase the thickness of the cover plate 300, improve the concrete grade, and improve the self-rigidity; two, bedding the channel steel 700 under the cover plate 300 to improve the bearing capacity; three, install the rubber pad 200 under the cover plate 300, Adapt to the dynamic load of the vehicle; 4. Fill the gap between the manhole cover and the concrete pavement panel with asphalt to adapt to the flexible extrusion caused by the driving of the veh

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap