Method for making black fungus tea

A fungus and tea soup technology, applied in the field of the preparation of fungus tea, can solve the problems of insufficient fusion, monotonous taste, scattered taste, etc., and achieve the effects of improving immunity, strong aroma and bright soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

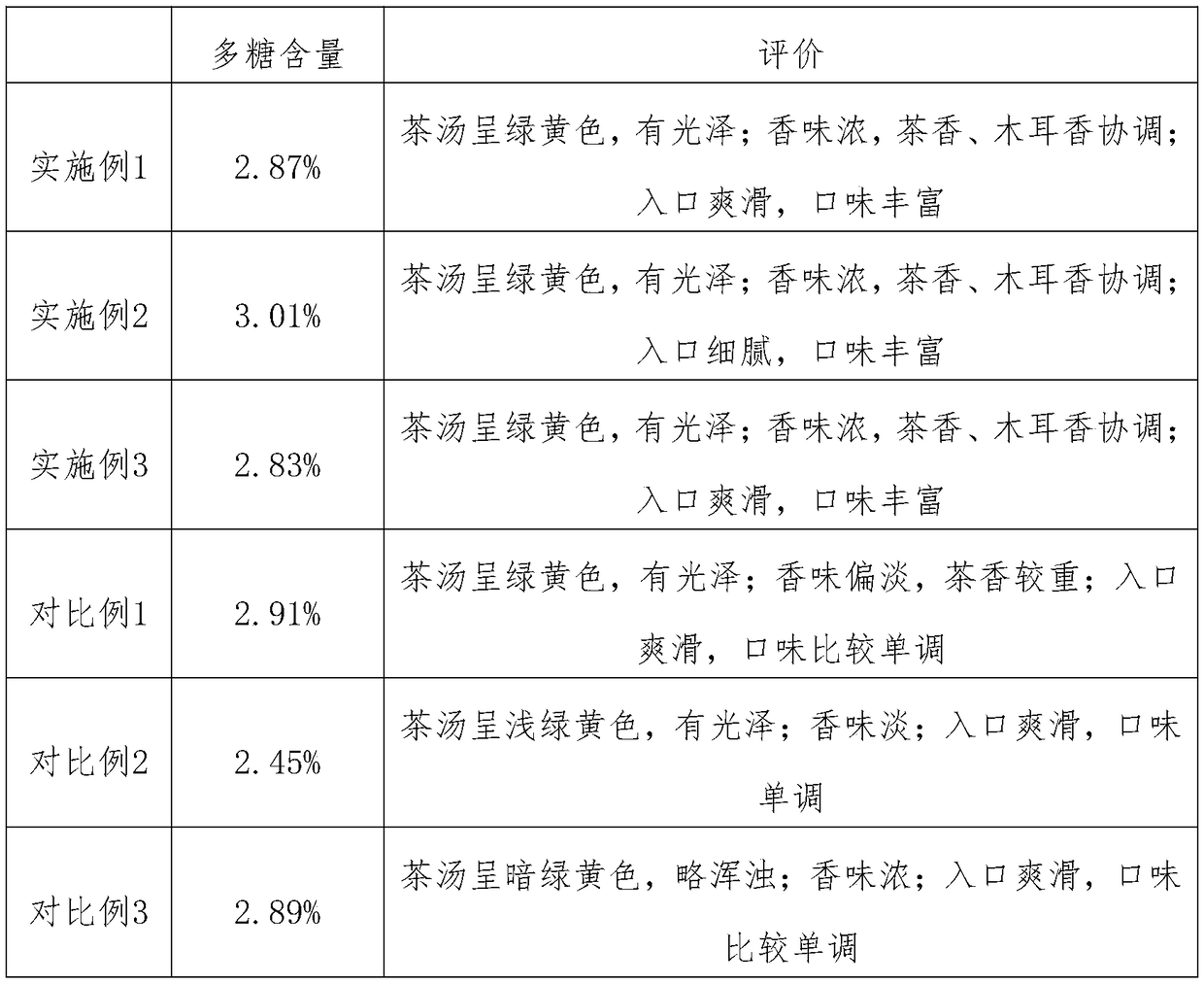

Examples

Embodiment 1

[0022] A preparation method of fungus tea, specifically comprising the following steps:

[0023] (1) Take the finished green tea and pulverize it, pass through a 100-mesh sieve to obtain 100g of green tea powder; add the green tea powder to 1500ml of boiling water and soak for 15 minutes to obtain tea soup;

[0024] (2) Take dried fungus, add it to tea soup, soak at 30-35°C for 4 hours, pass through a 60-mesh sieve, and obtain wet fungus and filter residue solution;

[0025] (3) Add the obtained filter residue solution into a steamer to make steamer water. After the wet fungus is drained, spread it evenly on a steaming plate, cover the pot, steam for 6 hours, cool down, and remove from the pot;

[0026] (4) drying the steamed fungus until the water content is 50-60%;

[0027] (5) Take 500g of fresh tea leaves and place them in a ventilated place until the water content is 65-70%, and then fix them at 220°C for 30s to obtain the finished leaves;

[0028] (6) After mixing the fun

Embodiment 2

[0031] A preparation method of fungus tea, specifically comprising the following steps:

[0032] (1) Grind the finished green tea, pass through a 100-mesh sieve to obtain 100 g of green tea powder; add the green tea powder to 1800 ml of boiling water and soak for 15 minutes to obtain tea soup;

[0033] (2) Take dried fungus, add it to tea soup, soak at 30-35°C for 9 hours, pass through a 60-mesh sieve, and obtain wet fungus and filter residue solution;

[0034] (3) Add the resulting filter residue solution into a steamer to make steamer water. After the wet fungus is drained, spread it evenly on a steaming plate, cover the pot, steam for 6 hours, cool down, and remove from the pot;

[0035] (4) drying the steamed fungus until the water content is 50-60%;

[0036] (5) Take 500g of fresh tea leaves and spread them in a ventilated place until the water content is 65-70%, and then fix them at 210°C for 35s to obtain the finished leaves;

[0037] (6) After mixing the fungus obtained

Embodiment 3

[0040] A preparation method of fungus tea, specifically comprising the following steps:

[0041] (1) Take the finished green tea and pulverize it, pass through a 100-mesh sieve to obtain 100g of green tea powder; add the green tea powder to 2000ml of boiling water and soak for 20min to obtain tea soup;

[0042] (2) Take dried fungus, add it to tea soup, soak for 6 hours at 30-35°C, pass through an 80-mesh sieve, and obtain wet fungus and filter residue solution;

[0043] (3) Add the obtained filter residue solution into a steamer to make steamer water. After the wet fungus is drained, spread it evenly on a steaming plate, cover the pot, steam for 6.5 hours, cool down, and remove from the pot;

[0044] (4) drying the steamed fungus until the water content is 50-60%;

[0045] (5) Take 500g of fresh tea leaves and place them in a ventilated place to spread until the water content is 65-70%, and then fix them at 200°C for 40s to obtain the finished leaves;

[0046] (6) After mixing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap