Method for improving specific surface area and adsorption performance of opoka

A technology of specific surface area and adsorption capacity, which is applied in the fields of non-metallic mineral processing and environmental engineering, can solve the problems of specific surface area and adsorption performance reduction and loss, and achieve the effect of pore transparency, permeability improvement and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

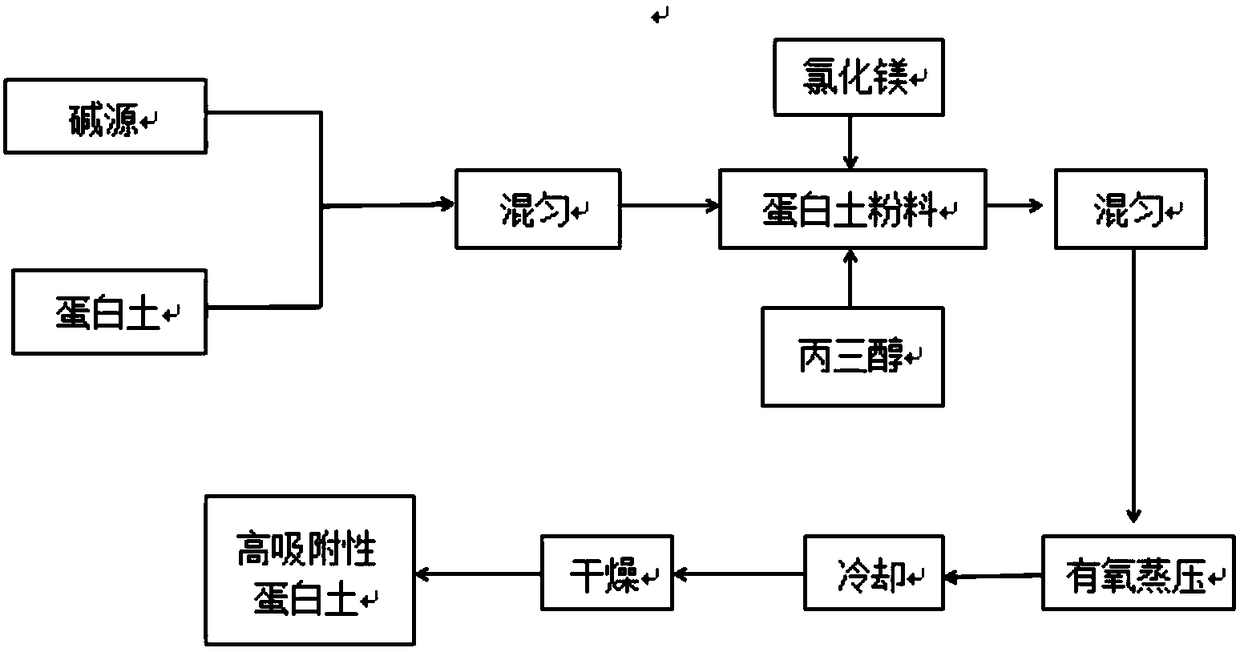

Method used

Image

Examples

Example Embodiment

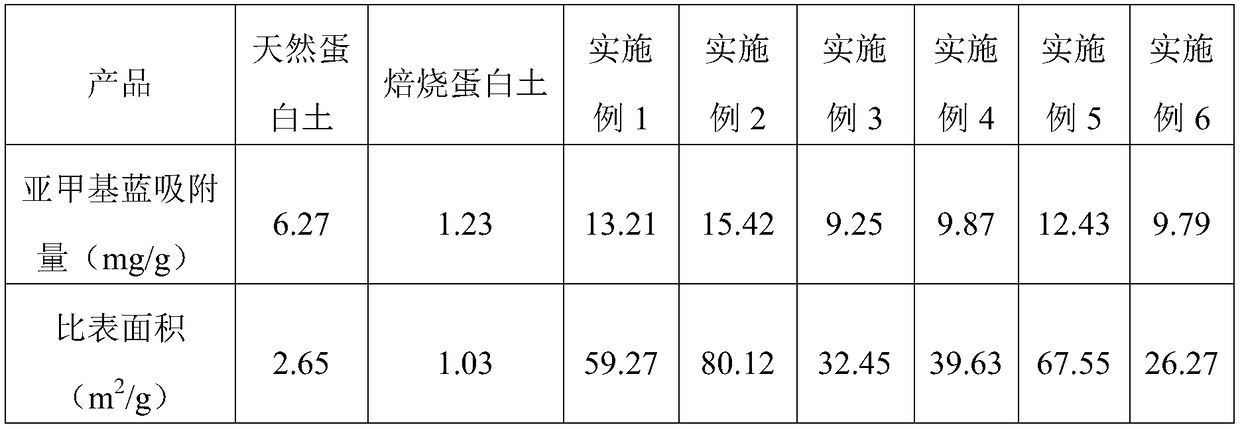

[0017] Example 1

[0018] (1) take by weighing natural protein soil 9g, NaOH 1g respectively, utilize vortex mixer to stir 30min, make it mix well, obtain preliminary protein soil powder;

[0019] (2) Weigh 1.9g MgCl 2 Mix it with 2.7g glycerol to make 1L mixed solution, take 50mL mixed solution, mix it with the preliminary protein soil powder evenly, and then add it into a 75mL ceramic crucible according to the solid-liquid mass ratio of 1:5. Put it in a high-pressure reactor and react at 160 °C for 12 hours; oxygen is not released during the heating process, so as to ensure that the reaction process is in an aerobic environment;

[0020] (3) After the reaction is completed, the protein soil is taken out and cooled to room temperature. After filtration, it is fully dried at 100° C., and pulverized to below 74 μm using a pulverizer to finally obtain protein soil powder with high specific surface area and adsorption performance.

Example Embodiment

[0021] Example 2

[0022] This example is basically the same as Example 1, except that the consumption of natural protein soil is 8.5g, and the consumption of NaOH is 1.5g.

Example Embodiment

[0023] Example 3

[0024] This example is basically the same as Example 1, the difference is: the consumption of natural protein soil is 9.5g, NaOH is replaced with CaO, and its consumption is 0.5g, the autoclave reaction temperature is 180 ℃, and the reaction time is unchanged.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap