Steam turbine equipment related method

An equipment-related, steam turbine technology, applied in the cleaning field, achieves the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

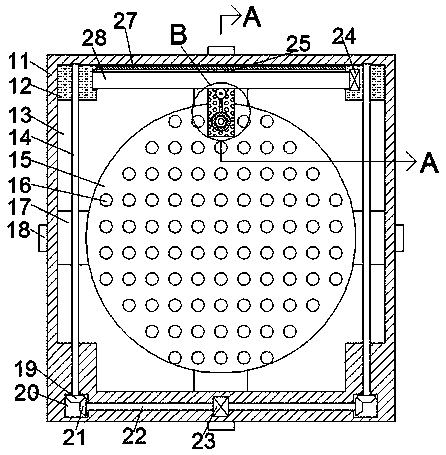

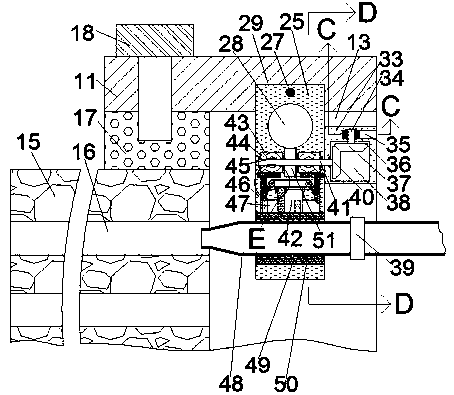

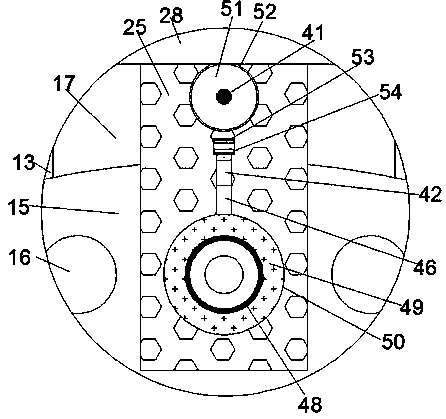

[0021] Such as Figure 1-Figure 6 As shown, a steam turbine equipment related method of the present invention, the equipment used in this method includes a device body 11, a transmission device provided in the device body 11, a telescopic device provided in the device body 11, and The moving device in the device main body 11, the transmission device includes a first cavity 13 arranged in the device main body 11 to penetrate back and forth, and the upper inner wall of the first cavity 13 communicates with each other. There is a second cavity 29, a first sliding block 25 is slidably arranged in the second cavity 29, the lower end of the first sliding block 25 extends into the first cavity 13, and the first A first rotating cavity 52 is provided in a sliding block 25, a turbine 51 is rotatably arranged in the first rotating cavity 52, and a first rotating shaft 41 is fixedly connected to the turbine 51. A second rotating cavity 43 is symmetrically provided in the side inner wall. Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap