Cutting board prefabricating edge trimming and dividing device

A technology of edge cleaning and cutting, applied in sawing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve the problem of polluting the production workshop environment, generating a large amount of debris and dust, and a large number of manual labor, etc. problems, to achieve the effect of reducing manual use, curbing the generation of debris and dust, and improving the speed of edge cleaning and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

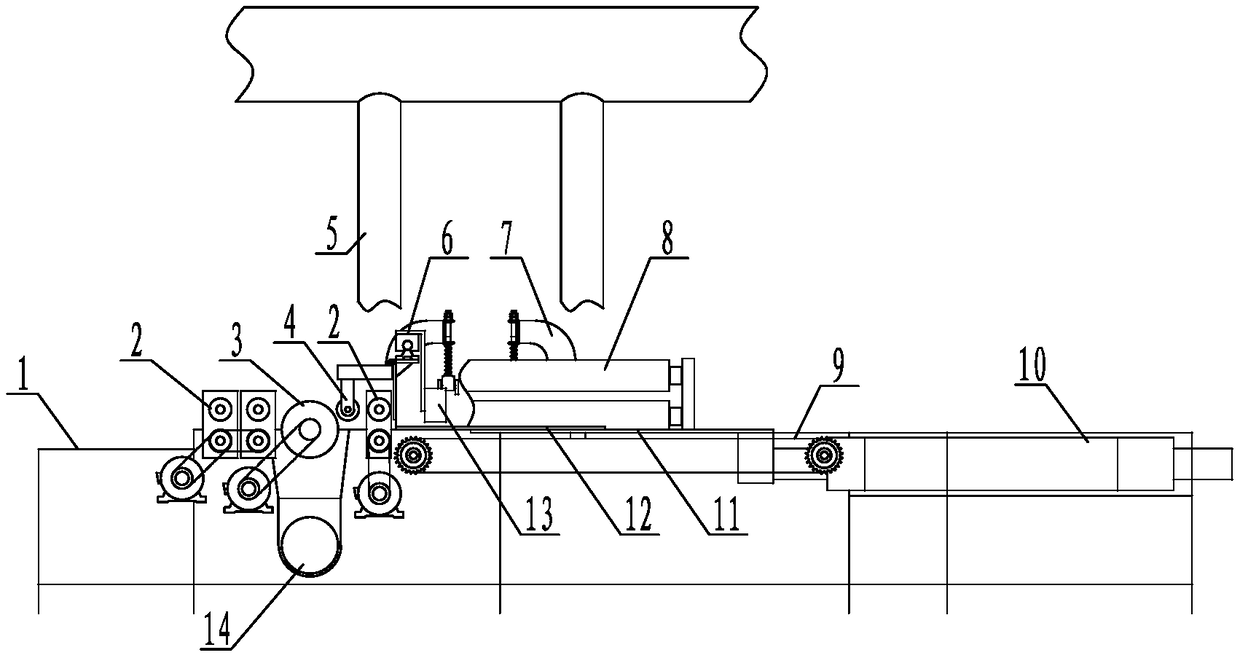

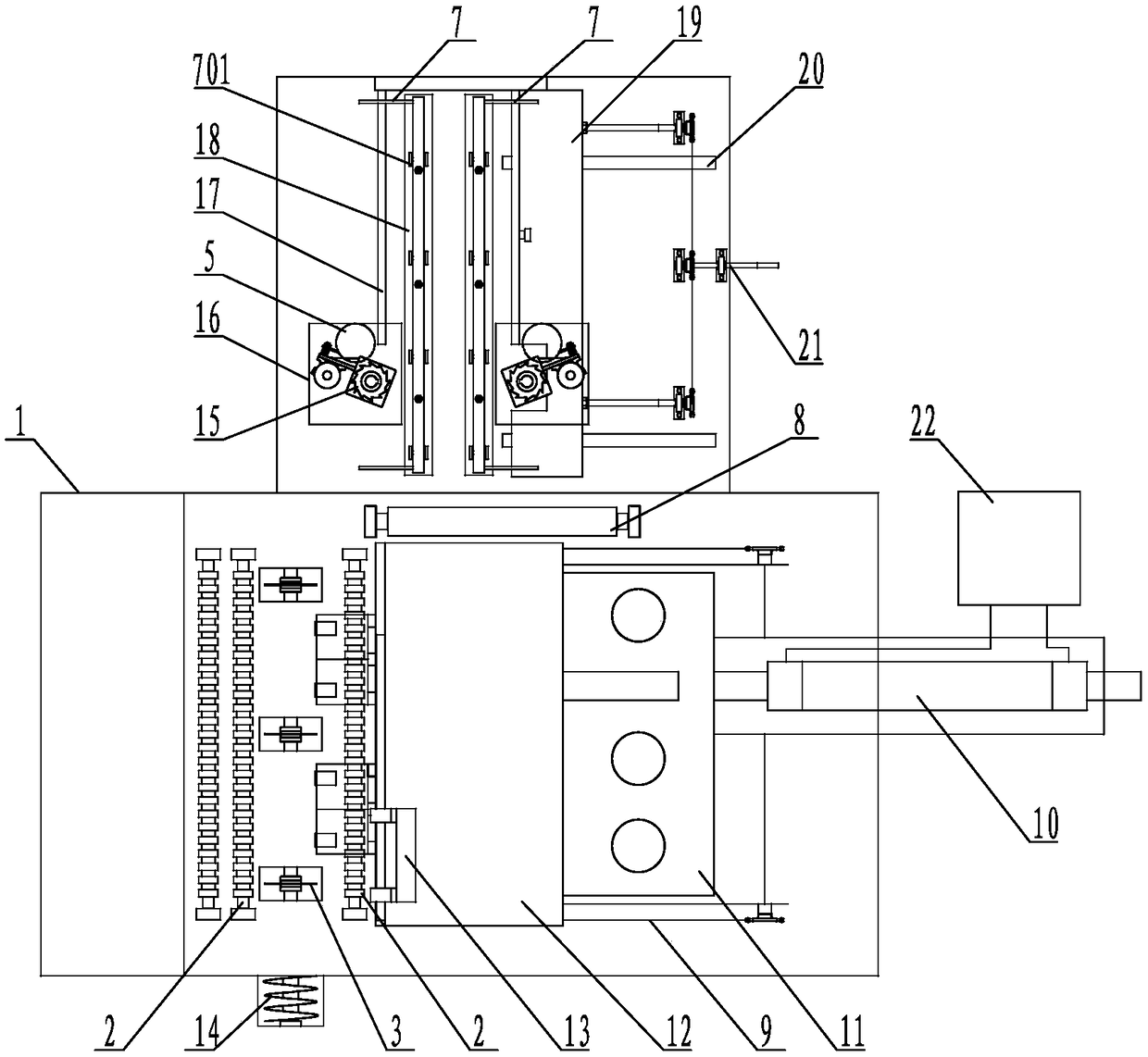

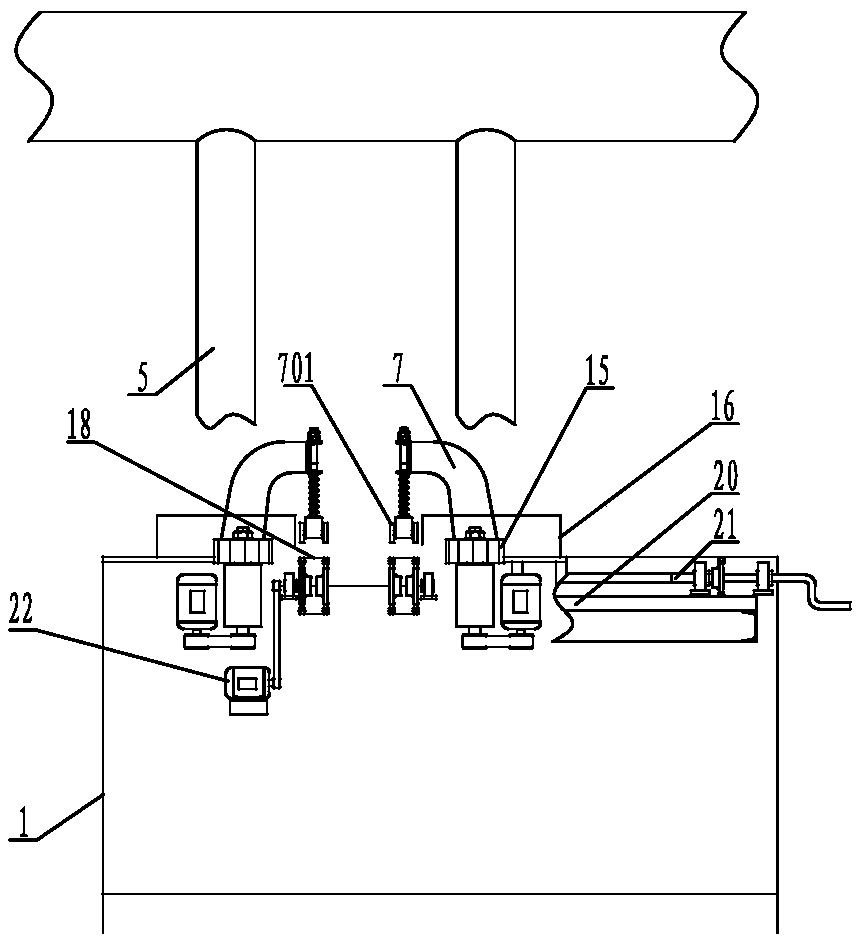

[0021] Below, the present invention will be further described in detail with reference to the drawings and embodiments.

[0022] figure 1 , figure 2 , image 3 Embodiments of the invention are shown. Its composition: consists of frame 1, board delivery roller 2, cutting knife assembly 3, board delivery roller 4, dust suction pipe 5, slider 6, roller bracket 7, board delivery roller 8, push plate Drive mechanism 9, platform drive mechanism 10, movable platform 11, movable push plate 12, length-adjusting top block 13, chip cleaning mixing drum 14, edge cleaning knife 15, dust cover 16, guide plate 17, edge cleaning conveying mechanism 18, The width adjustment plate 19, the adjustment slide rail 20, the adjustment rod 21, the oil pump 22 and the fasteners are assembled and combined.

[0023] The structural features of specific embodiments are:

[0024] A cutting board prefabricated edge clearing and cutting equipment is characterized in that it is composed of an edge clearing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap