Making method of sauce-flavor beef granules

A production method and technology of beef granules, which are applied in food science, application, food ingredients, etc., can solve the problems of monotonous taste, reduce the taste experience of users, and single manufacturing process of beef sauce, so as to achieve pure aroma, remove bad smell, and unique flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

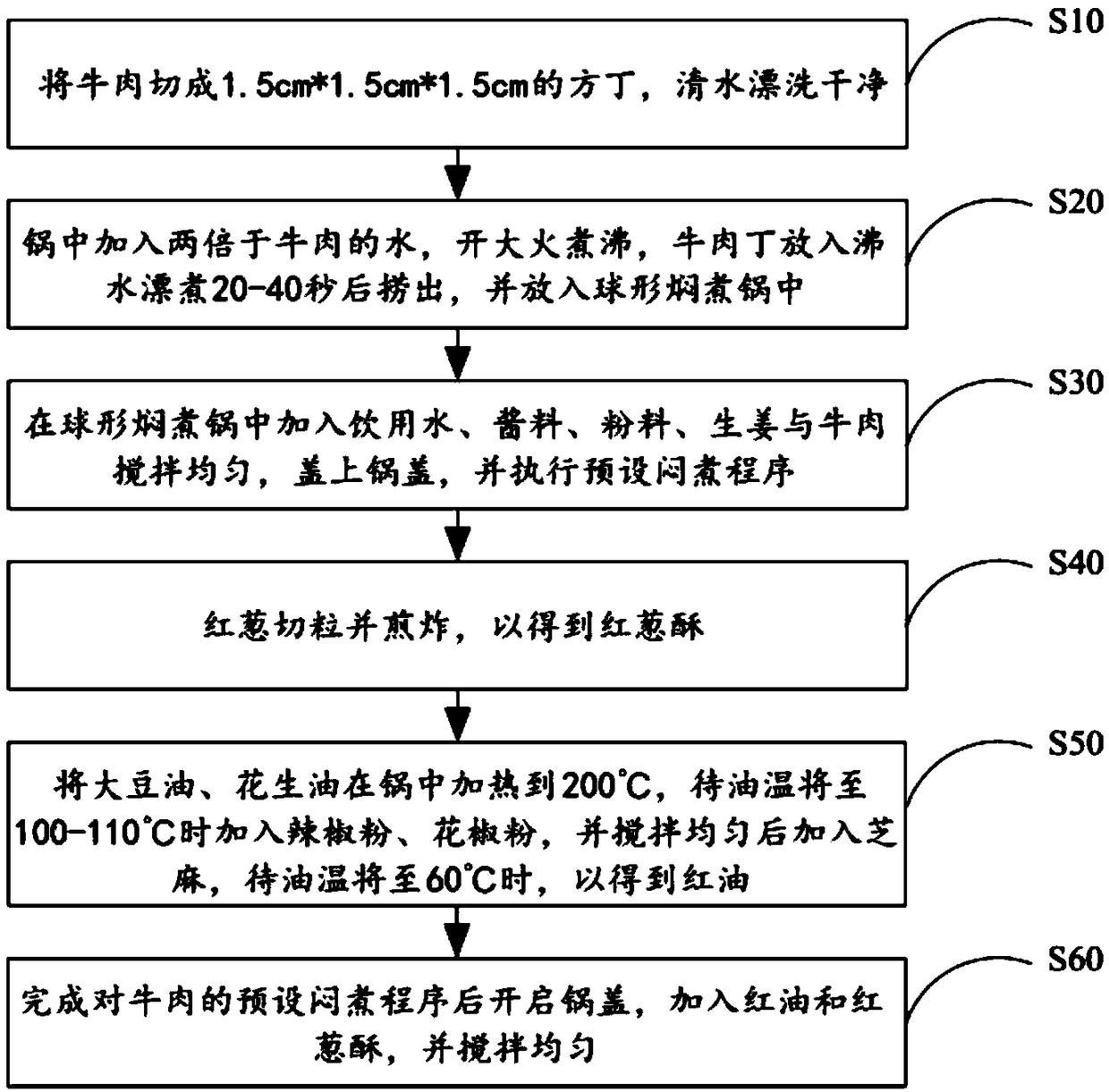

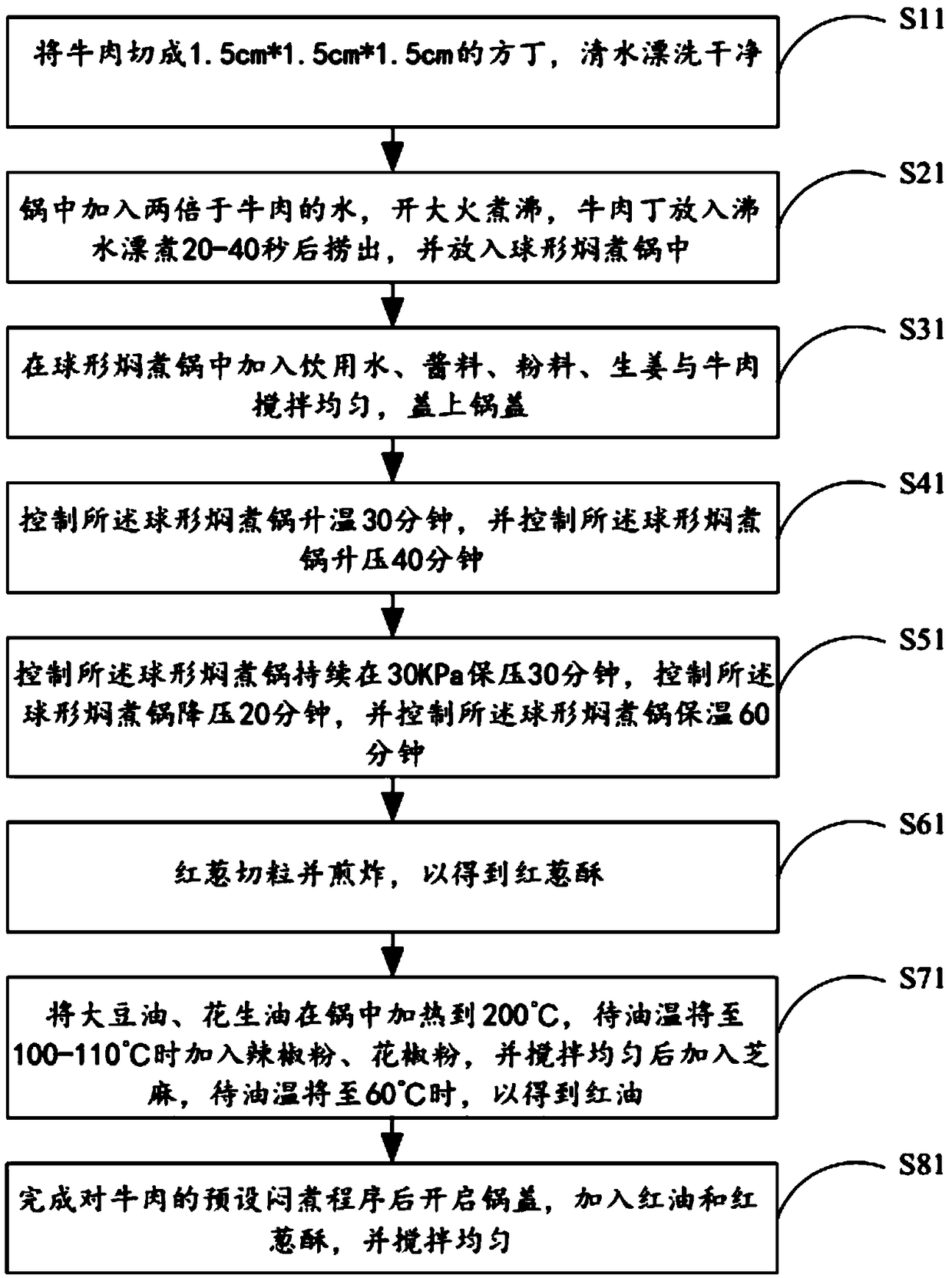

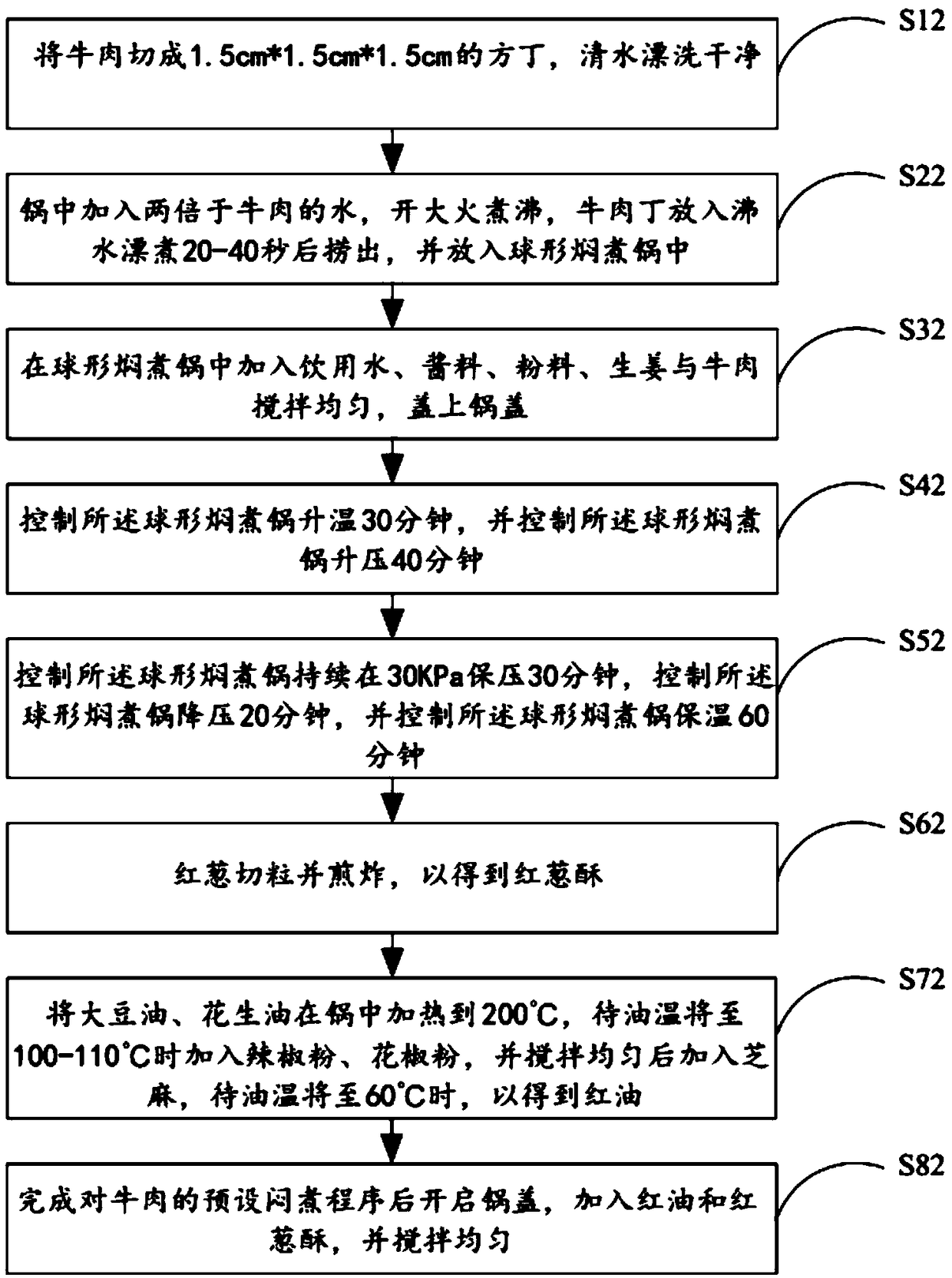

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate a better understanding of the present invention, the present invention will be further explained below in conjunction with the accompanying drawings of related embodiments. Embodiments of the invention are shown in the drawings, but the invention is not limited to the preferred embodiments described above. Rather, these embodiments are provided so that the disclosure of the invention will be more thorough.

[0030] In the description of this specification, descriptions with reference to the terms "one embodiment", "some embodiments", "example", "specific examples", or "some examples" mean that specific features described in connection with the embodiment or example , structure, material or characteristic is included in at least one embodiment or example of the present invention. In this specification, schematic representations of the above terms do not necessarily refer to the same embodiment or example. Furthermore, the specific features, structur

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap