Fan direct-driven variable pitch system based on digital twin and optimum design method

A technology of variable pitch and fan, which is applied in the direction of mechanical equipment, wind turbines, engines, etc., can solve the problems of long transmission lines of variable pitch systems, difficulties in optimization and improvement, and many transmission links, so as to improve the effective running time and avoid economical problems. and safety hazards, the effect of excellent economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

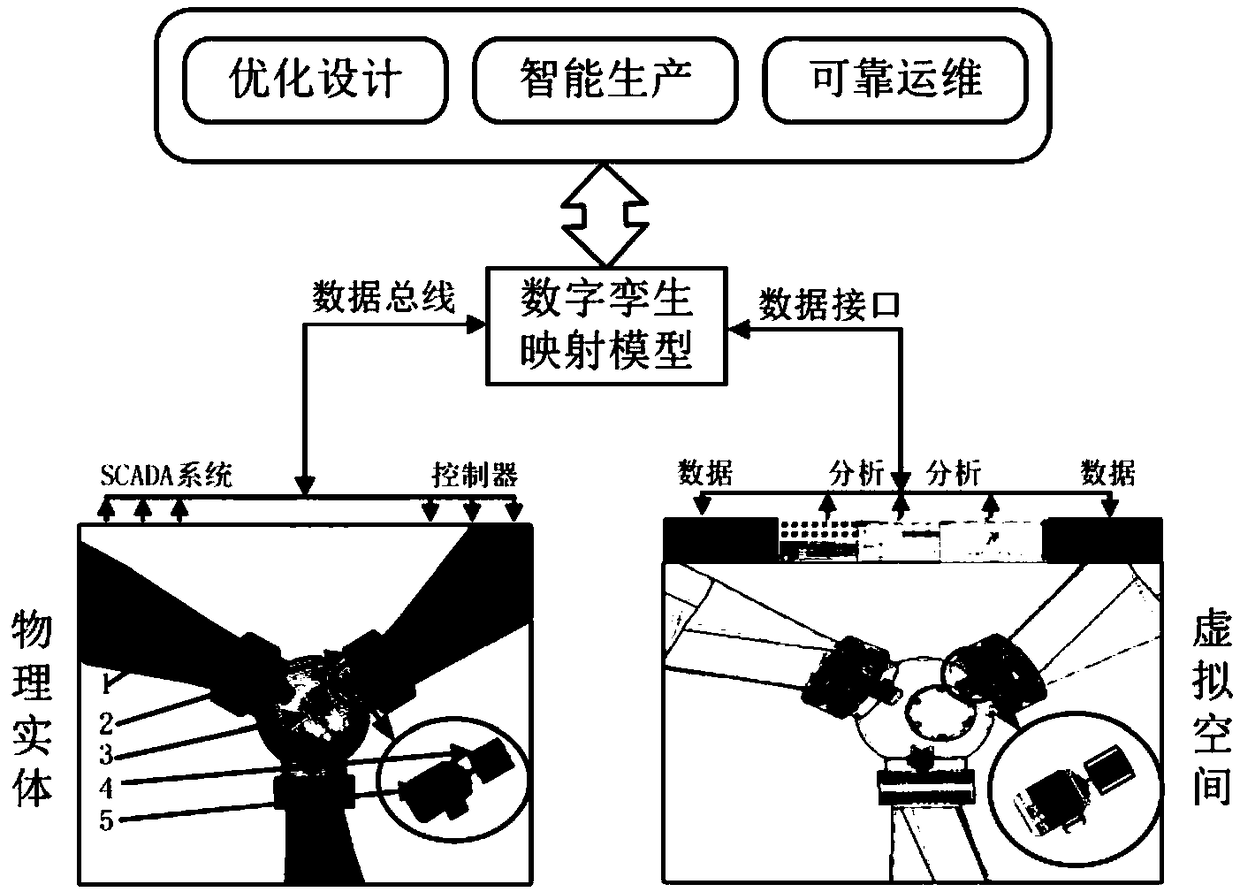

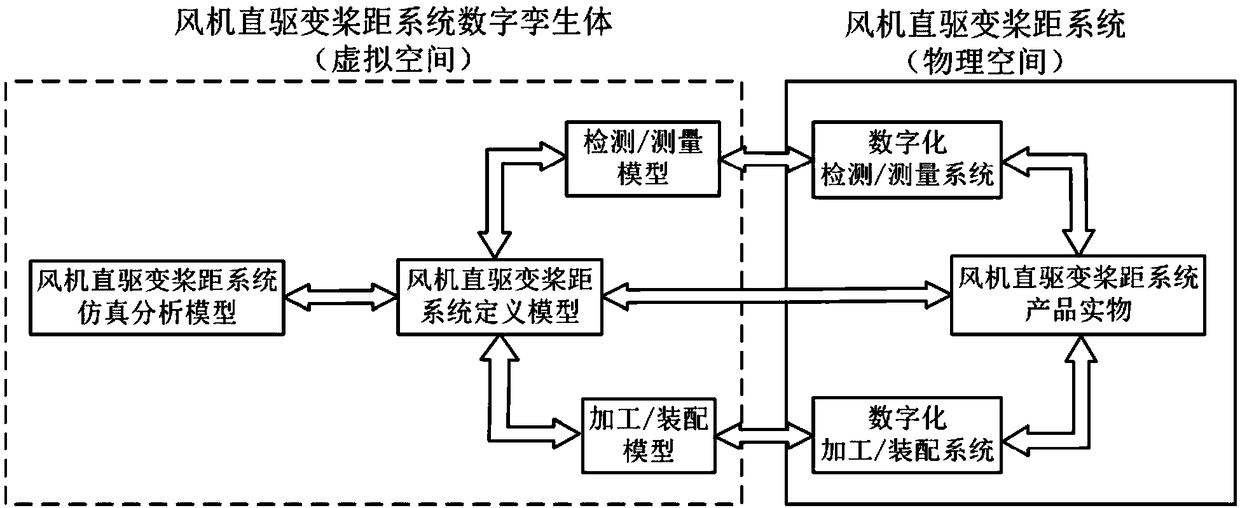

[0036] Example 1: figure 1 Shown is the digital twin product reference system architecture, the wind turbine direct drive pitch system includes: the wind turbine direct drive pitch system mainly includes permanent magnet motor frequency converter 3, permanent magnet synchronous motor 5, pitch pinion 4. The pitch variable gear ring 2 and the blade 1. The permanent magnet synchronous motor directly drives the pitch pinion to rotate as the driving source. The pitch variable pinion drives the pitch variable gear ring to rotate, and the blades also follow Rotation, the permanent magnet motor inverter controls the operation of the permanent magnet synchronous motor, and completes the wind turbine pitch change work under the control of the permanent magnet motor inverter.

[0037] To change the pitch of the wind turbine, the specific steps are as follows:

[0038] A. Through the SCADA system and sensors installed in the physical entity of the wind turbine direct drive variable pitch sy

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap