Purifying method for crude dioxane

A purification method, the technology of dioxane, applied in the direction of organic chemistry, etc., can solve the problems of low recycling rate, inability to achieve purity, pollution, etc., and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

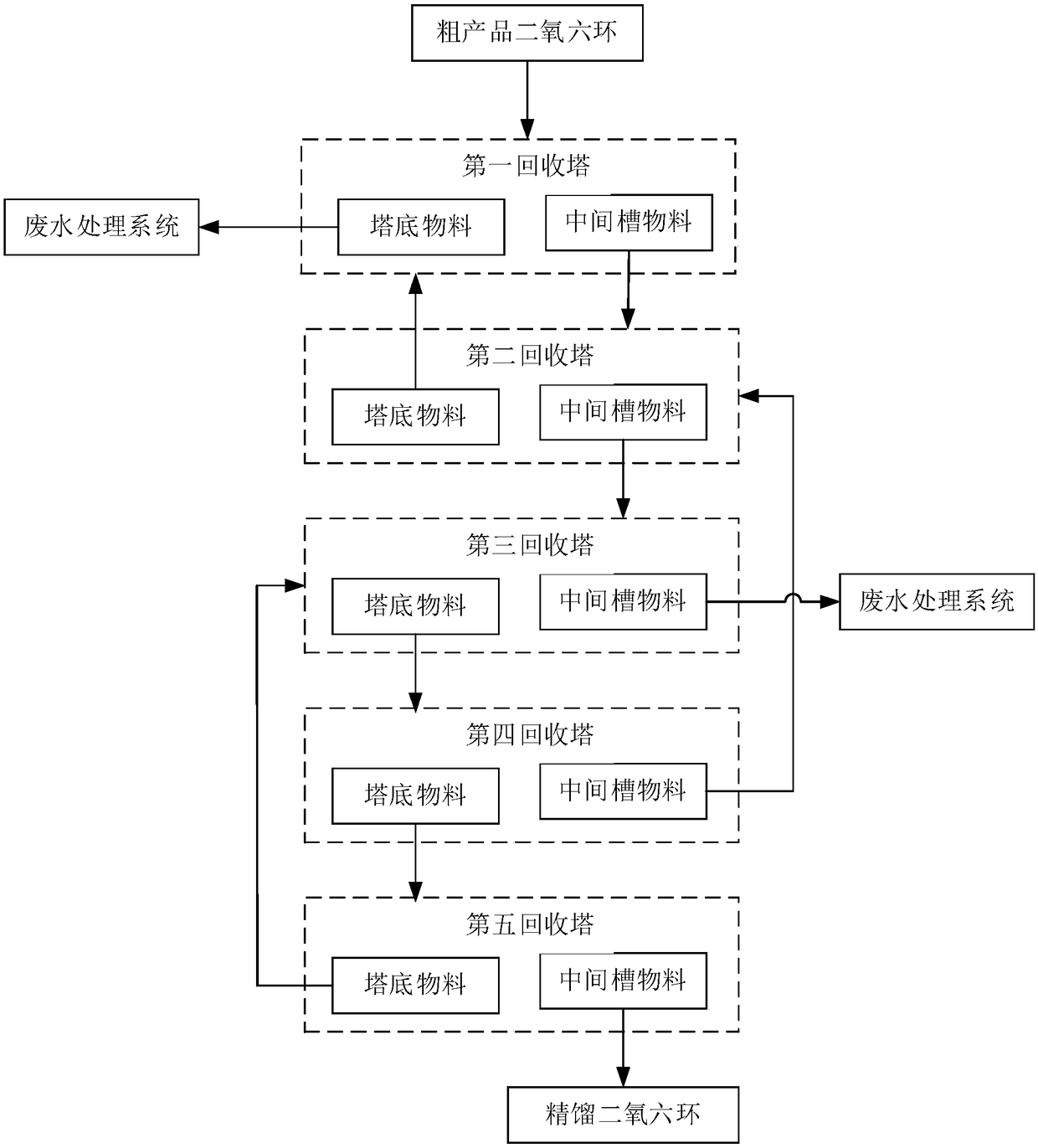

[0018] Such as figure 1 As shown, the present embodiment 1 provides a method for purifying the crude product dioxane, comprising: at least 5 recovery towers; the crude product dioxane is suitable for successively passing through each recovery tower for gradual purification. The recovery towers are all atmospheric towers. The specific purification process is as follows:

[0019] The first step of purification: the crude product dioxane (the content of dioxane is about 3-8%) is transported to the first recovery tower (independent gap operation), the temperature is controlled at 90-110°C, and the gas phase at the top of the tower passes through the condenser After condensation, it is collected in the middle tank of the first recovery tower (the content of dioxane is about 20%), and a certain reflux ratio is controlled; the bottom material (basically water) can be treated as wastewater.

[0020] The second step of purification: pump the material in the middle tank of the first r...

Embodiment 2

[0026] On the basis of embodiment 1, present embodiment 2 provides a kind of dioxane purification system, comprising:

[0027] At least 5 recovery towers.

[0028] For the specific structure and implementation process of the recovery tower, please refer to the relevant discussion of Embodiment 1, and details will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap