Membrane treatment method for desulfurization wastewater of coal-fired power plant

A desulfurization wastewater and membrane treatment technology, applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost of chemicals, inability to make full use of, and increase in treatment costs, and reduce energy consumption. , huge economic and social benefits, the effect of reducing the amount of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1 according to figure 1 The process flow chart in the middle is to carry out the membrane treatment of desulfurization wastewater concentration and reduction. The specific steps are as follows:

[0024] 1) After the desulfurization wastewater is pretreated in the clarifier, it is passed through the circulating ultrafiltration for filtration, and the recovery rate of the circulating ultrafiltration is 100%;

[0025] 2) After step 1), the circulating ultrafiltration product water is concentrated through the vibrating membrane, the recovery rate is 65%, 65% of the product water is obtained for reuse, and 35% of the concentrated water is obtained and enters the slag spraying system.

[0026] The recovery rate of desulfurization wastewater in this example is 65%.

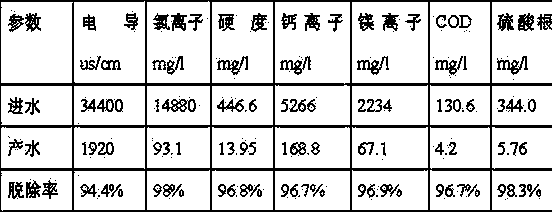

[0027] The water quality indicators before and after desalination wastewater treatment in the example are shown in Table 1

[0028] Table 1. Comparison table of water quality indicators before and after mem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap