Integrated module of oxygen inhalation and negative pressure suction

An integrated module and negative pressure technology, applied in the direction of suction equipment, respirators, valves, etc., can solve problems such as medical accidents, achieve energy saving effects and good economic efficiency, broaden the application field, and improve the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

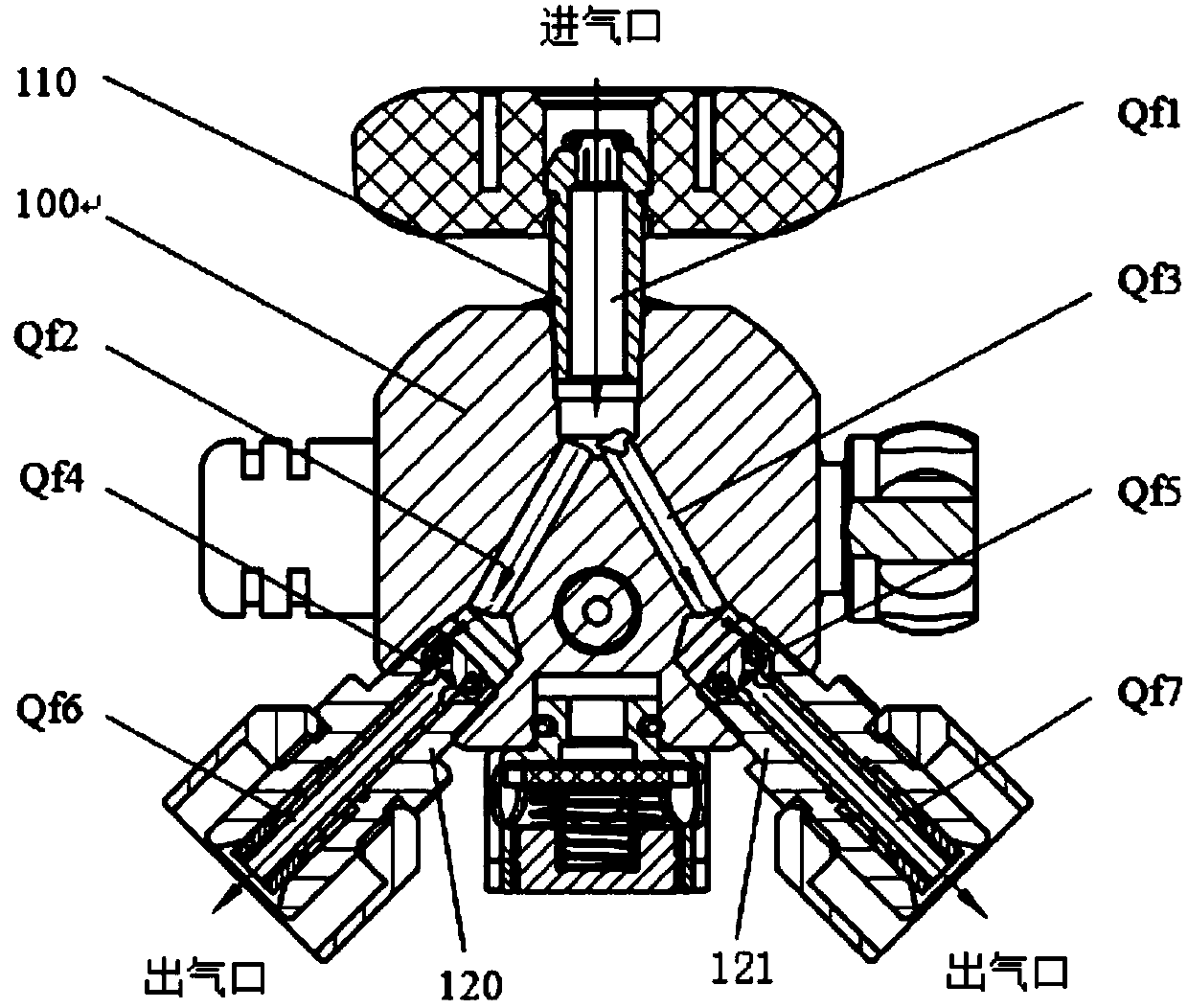

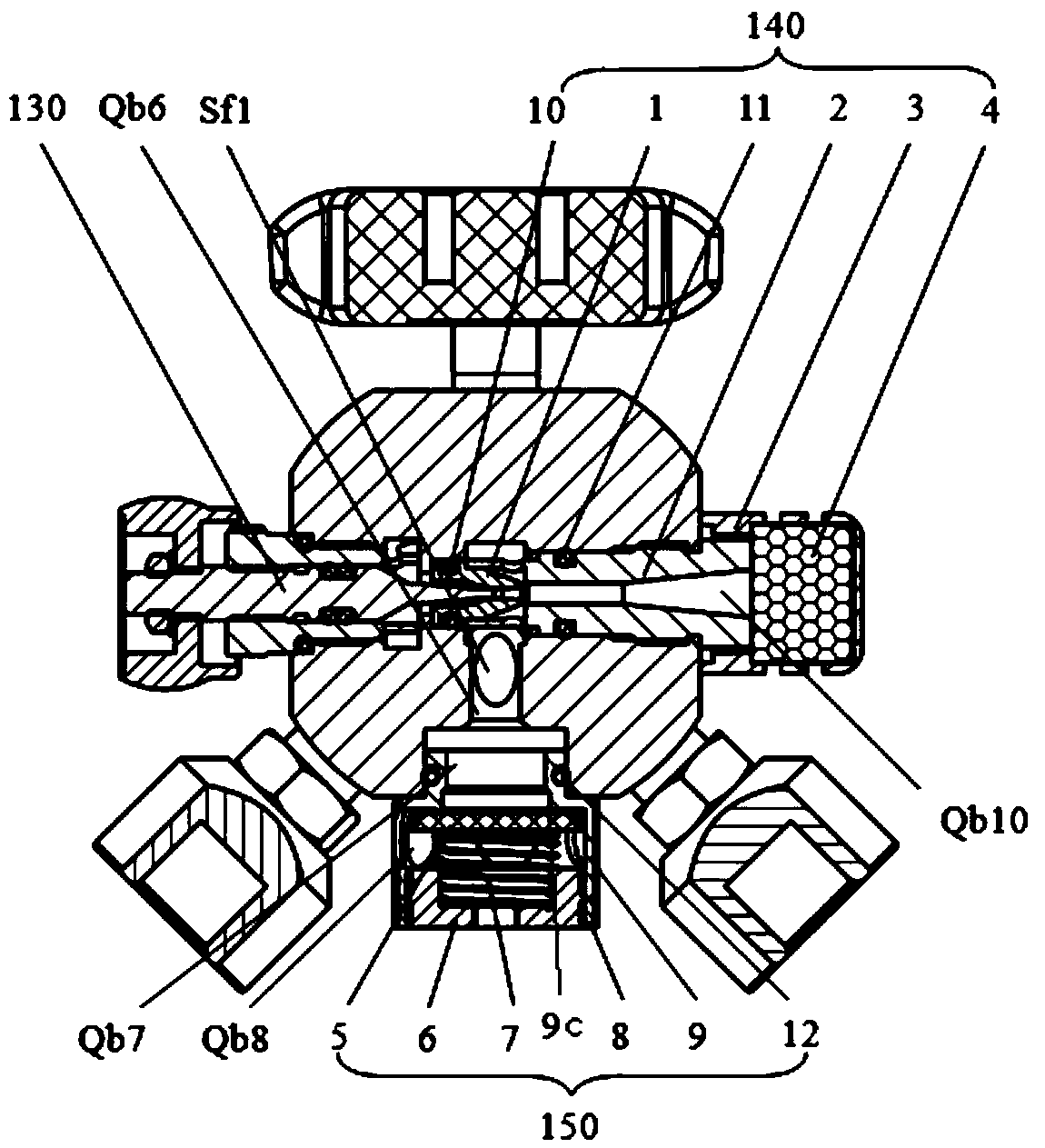

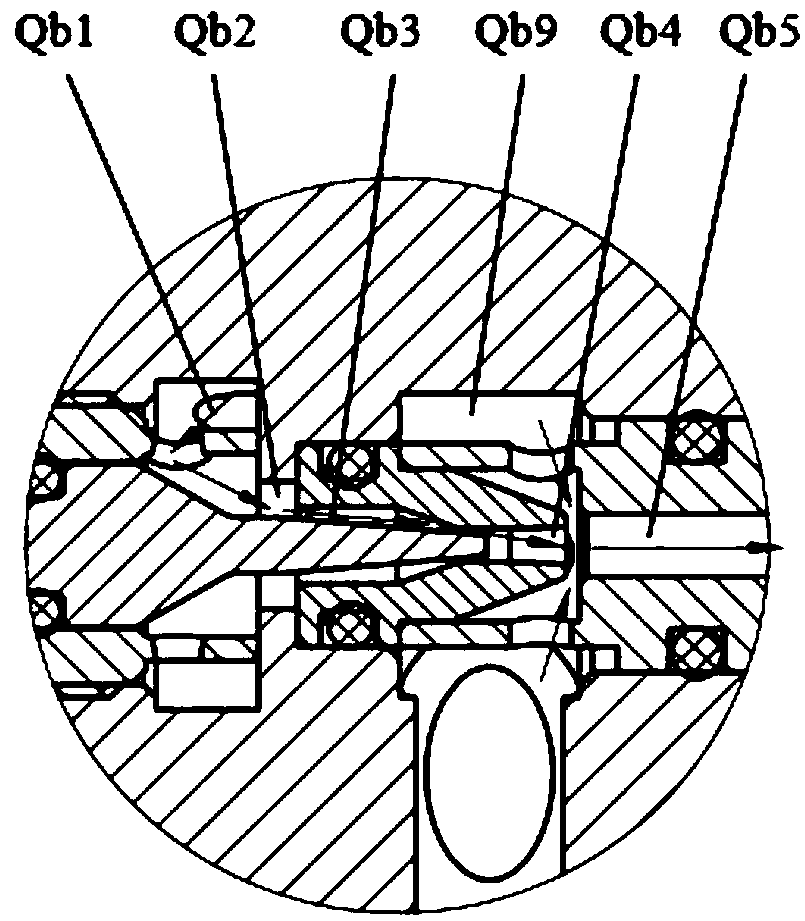

[0035] see Figure 1 to Figure 5 As shown, the present invention discloses an oxygen inhalation and negative pressure suction integrated module, including a valve body 100 and an air inlet joint 110 arranged on the valve body 100, a first air outlet terminal 120, a second air outlet terminal 121, a regulating needle valve 130, Negative pressure generator 140, negative pressure safety valve 150.

[0036] The valve body 100 is provided with an air inlet joint interface, a first air outlet terminal interface, a second air outlet terminal interface, a regulating needle valve interface, a negative pressure generator interface, a negative pressure safety valve interface, a threaded hole Sf1, and a negative pressure suction port (Fig. Not marked above);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap